The permanent magnets are coated with a thin layer of heavy rare earth metal (HRE) and then undergo special heat treatment. This allows us to create smaller and thinner magnets that have higher resistance to opposing magnets or coils without the risk of demagnetization. Grain Boundary Diffusion (GBD) process is an effective approach for enhancing coercivity with low material cost.

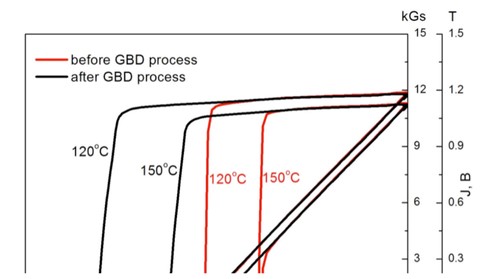

Figure 1. 1 H curves before and after GBD

Stanford Magnets adopts the following two methods:

Enhanced Diffusion Rates: Grain boundary diffusion occurs at a significantly faster rate compared to lattice diffusion (diffusion within the grains) because the atomic packing is less dense at the grain boundaries. This can be advantageous in processes like sintering, where rapid diffusion can lead to faster and more efficient densification of powders.

Material Strengthening: The process can be exploited to improve the mechanical properties of materials. For example, by diffusing alloying elements into the grain boundaries, one can enhance the strength and hardness of the material through mechanisms such as grain boundary strengthening and the formation of precipitates that impede dislocation movement.

Temperature Dependence: The rate of grain boundary diffusion increases with temperature, making it a critical factor in high-temperature applications. Understanding how diffusion behaves at different temperatures helps in designing materials that can withstand high-temperature environments, such as in aerospace and power generation industries.

Impurity Segregation: Grain boundary diffusion also influences the segregation of impurities to the grain boundaries, which can either be beneficial or detrimental to the material's properties. Controlled segregation can improve corrosion resistance and strength, while uncontrolled segregation can lead to embrittlement and decreased ductility.

Phase Transformations: The movement of atoms along grain boundaries can lead to changes in the microstructure, such as phase transformations, that significantly affect the material's overall properties. This is crucial in metallurgical processes and in the development of advanced materials with tailored properties.

Grain boundary diffusion is exploited in various applications, including materials processing and fabrication techniques, to achieve desired material characteristics. For instance, it plays a key role in the heat treatment of metals, ceramic processing, and the manufacturing of semiconductors and electronic components. Additionally, understanding and controlling grain boundary diffusion is essential in the development of high-performance materials for specific applications, such as thermal barriers, superalloys, and nanostructured materials.

Send us an Inquiry now to find out more Information and the latest prices, thanks!

United States

Drop files here or