Typically, the cost of a torque coupling or linear coupling exceeds the cost of common mechanical solutions, so couplers are often used in an aggressive environment where mechanical linkages are not feasible, such as:

- -High pressure

- -Temperature Extremes

- -Caustic liquids or gasses

- -High degree of particulates or fouling agent

Linear Couplers

A linear coupler is simpler compared with a torque couplers. It can be two magnets or comprised of engineered arrays containing multiple magnets of various configurations. The required coupling force and the operating environment are the prime design variables.

There are many variations of Linear Couplers. The fundamental similarity is that the coupler’s "halves" are "linked" through a gap. One "half" can propagate the other "half" without contact. All of the common and unique designs for Linear Couplers try to minimize cost, increase performance, and make use of the application-specific geometry.

One common style of Linear Couplers is simple magnets on a backing-plate. The magnets are sized based on the gap and desired force to be transferred.

Torque Coupling

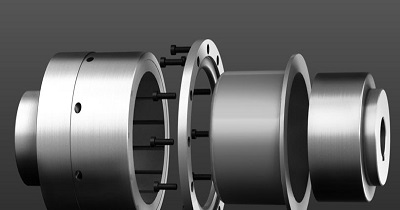

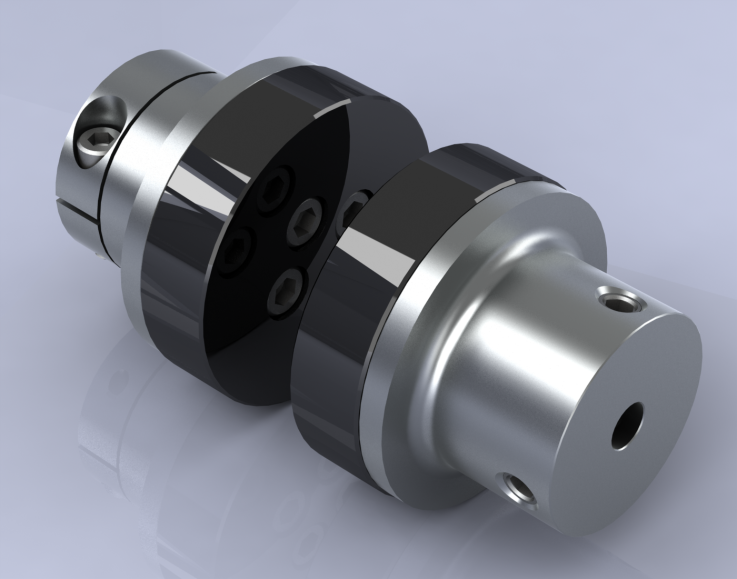

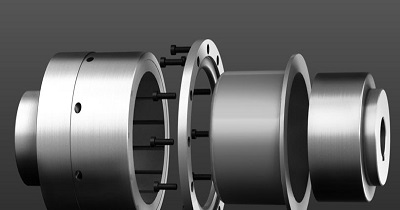

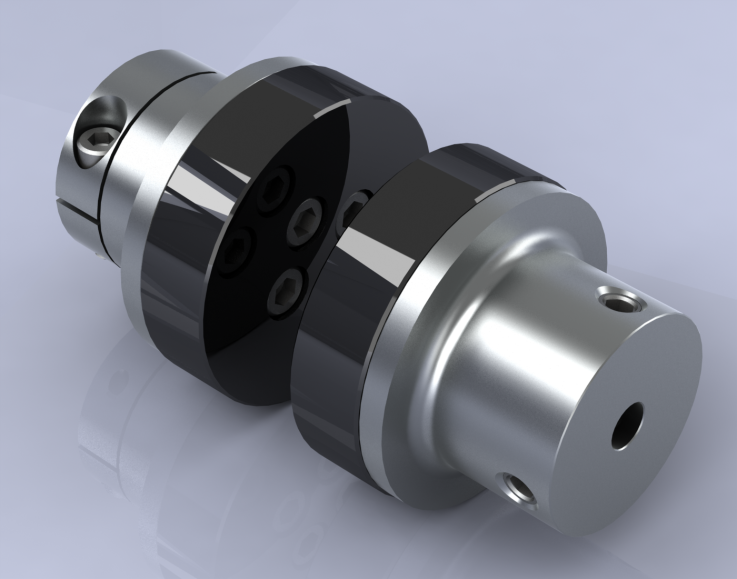

Two versions of the synchronous style of torque coupling: "Face to Face" and "Coaxial".

- Face-to-Face: Face-to-Face torque coupling is comprised of disc-shaped assemblies. This torque coupling is a good low-cost solution when the required torque, speed, and size restraints are moderate.

- Coaxial: Coaxial torque coupling is comprised of an inner assembly (half) and an outer assembly (half). It usually costs more than Face to Face torque coupling but requires less space.