Different Samarium Cobalt Magnets Series: SmCo 1-5 and SmCo 2-17

SmCo 1-5

--Composition and Features:

For samarium cobalt magnets Series 1-5 which is shortened as SmCo5, they have one atom of rare earth Samarium and five atoms of Cobalt. By weight this samarium cobalt magnet alloy will typically contain 36% Samarium with the balance Cobalt. The energy products of these samarium cobalt alloys range from 16 MGOe to 25 MGOe. These Samarium Cobalt magnets generally have a reversible temperature coefficient of -0.05%/°C. Saturation magnetization can be achieved with a moderate magnetizing field. This series of Samarium Cobalt magnet is easier to calibrate to a specific magnetic field than the SmCo 2-17 series magnets.

--Magnetization and Machining

In the presence of a moderately strong magnetic field, unmagnetized magnets of this series will try to align its orietation axis to the magnetic field. Unmagnetized magnets of this series when exposed to moderately strong fields will get slightly magnetized. This can be an issue if post processing requires that the magnet be plated or coated. The slight field that the magnet picks up can attract debris during the plating or coating process causing for a potential plating or coating failure or a mechanically out of tolerance condition.

Machining or grinding this magnet by the user is discouraged. This material must be ground using diamond cutting and grinding tools and a significant amount of water based coolant. Dry ground powder can ignite spontaneously with a small spark. The coercivity is controlled by a process known as "nucleation".

SmCo 2-17

--Composition and Features

For samarium cobalt magnets Series 2-17 which is shortened as Sm2Co17, they are an age hardening type with a composition of two atoms of rare earth Samarium Cobalt and 13-17 atoms of transition metals (TM). The TM content is rich in cobalt, but contains other elements such as iron and copper. Other elements like zirconium, hafnium and such may be added in small quantities to achieve better heat treatment response. By weight the alloy will generally contain 25% of Samarium.

The maximum energy products of these alloys range from 20 MGOe to 32 MGOe. These alloys have the best reversible temperature coefficient of all rare earth alloys, typically being -0.03%/°C. The "second generation" Samarium Cobalt materials can also be used at higher temperatures. The most advanced Samarium Cobalt material has a guaranteed maximum energy product of 29.5 MGOe minimum. All the SmCo alloys with energy products that are 22 MGOe and higher are made from the Series 2-17 alloy.

--Magnetization and Machining

SmCo 2-17 magnets, composed of approximately 25% samarium and 75% cobalt with trace elements like iron and copper, are magnetized by aligning powdered material in a magnetic field during compaction, sintering it at high temperatures, and then exposing it to a strong magnetic field of around 30-40 kOe. These magnets can be isotropic (magnetized in any direction) or anisotropic (with a preferred magnetization direction).

Machining SmCo 2-17 magnets is challenging due to their brittleness and requires diamond grinding or wire EDM, with precautions such as using coolant and slow feed rates to avoid damage. Post-machining, the magnets are often coated to enhance durability. These magnets are ideal for high-temperature applications in aerospace, automotive, and industrial sectors due to their high coercivity and resistance to demagnetization.

SmCo 1-5 and SmCo 2-17, Which Is Better?

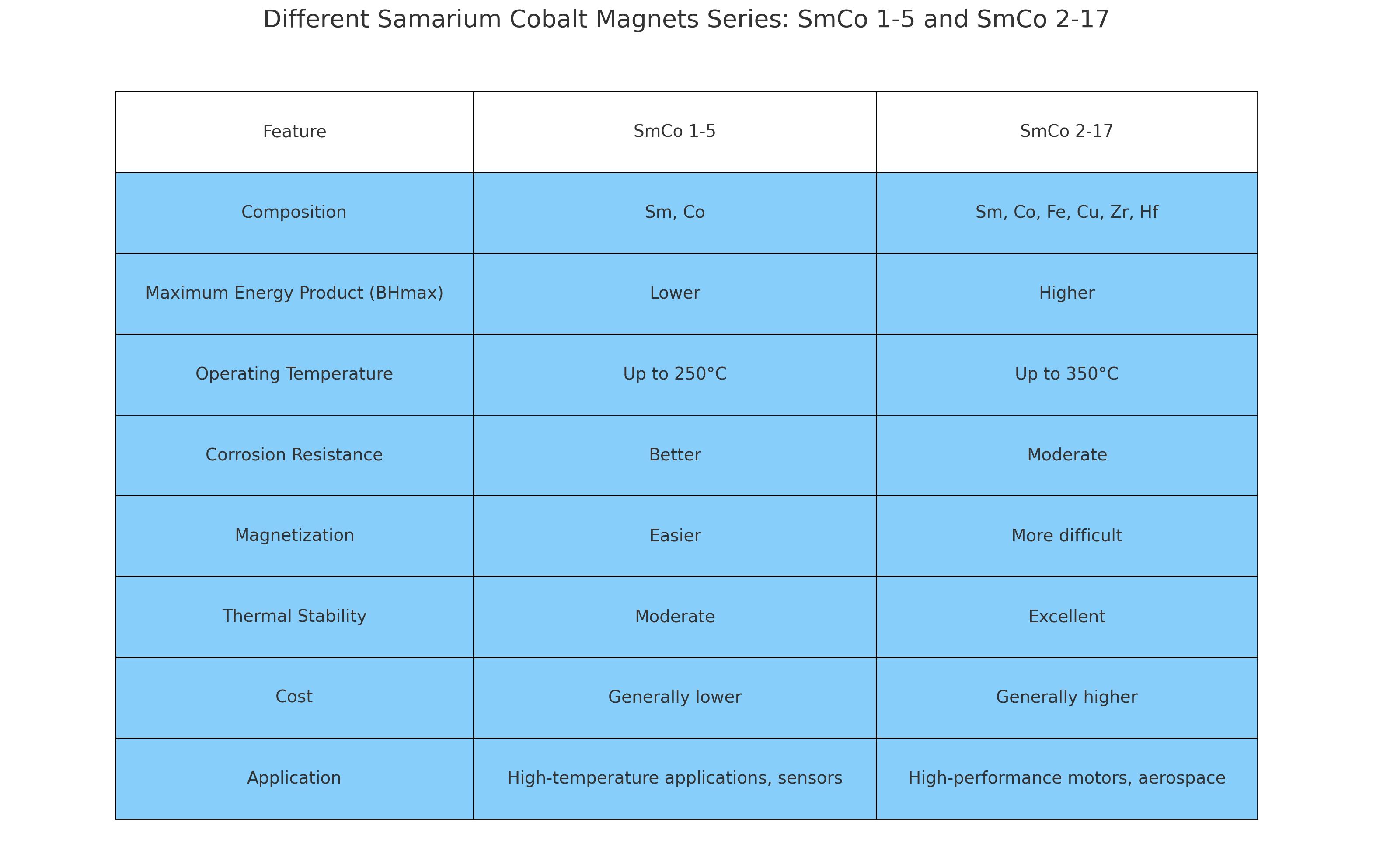

Let's compare SmCo 1-5 and SmCo 2-17 in a table format to highlight their differences and advantages:

- SmCo 1-5: Known for its simplicity in composition and better corrosion resistance. It is easier to magnetize and typically used in applications where moderate performance and better corrosion resistance are needed, such as sensors and other high-temperature applications.

- SmCo 2-17: Offers higher energy products and excellent thermal stability, making it suitable for high-performance applications like aerospace and high-performance motors. It can operate at higher temperatures but is generally more expensive and harder to magnetize.

Both types have their own specific advantages and are chosen based on the requirements of the application. For more information about SmCo Magnets, please check Stanford Magnets.