Radial vs Axial Flux Motor: Which Is Suitable for the Future of Electric Machines?

Electric motors are the cornerstone of many technologies from industrial machinery to electric vehicles (EVs), drones, and renewable energy systems. In response to increasing demand for high efficiency, reduced weight, and smaller machines, engineers and designers are more and more confronted with a decision between two predominant motor architectures, the radial flux motor, and the axial flux motor.

While both types do essentially the same fundamental job—converting electrical power into mechanical movement—their structures, working nature, and applicability to specific purposes differ radically. Let us compare their efficiency, cooling mechanism, materials, and applications.

[1]

[1]

Knowing the Fundamentals

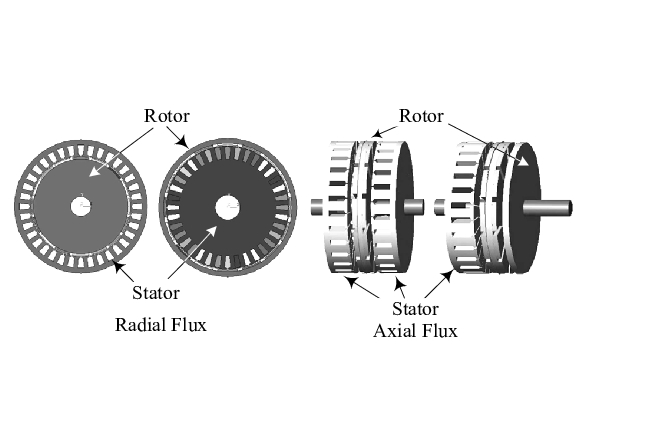

The core of all motors is the magnetic circuit along which magnetic flux flows from stator to rotor to create torque. The only difference between radial and axial flux motors is the path that magnetic flux follows.

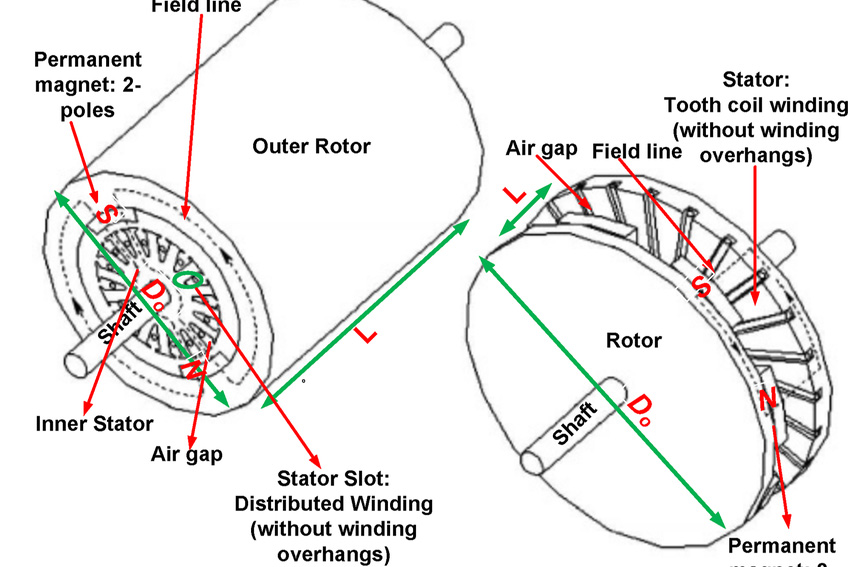

In radial flux motors, the magnetic flux moves radially—either radially outward from the rotor center towards the stator or radially inward. This arrangement has been the industry standard in electric motors for over a century and reigns supreme in electric cars today due to its simplicity and established production infrastructure.

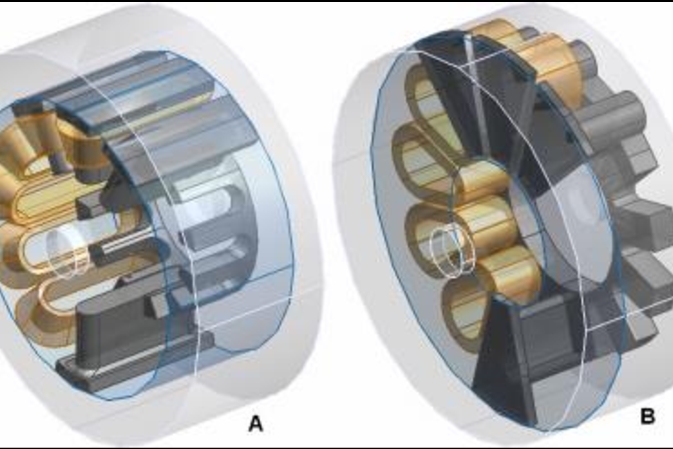

Axial flux motors, however, are so constructed that the magnetic flux is aligned parallel to the axis of rotation. These motors are pancake-shaped with both the rotor and stator being discs. Because of the axial construction, there is a reduced and straight flux path between the poles, and that's a significant contributor towards its improved performance in several areas.

Related reading: An Overview of Axial Flux Motor: Benefits, Types, and Uses

[2]

[2]

Magnetic Path and Efficiency

In radial type machines, the flux path is very long. It originates from a rotor pole, travels to a stator tooth, then to the stator back iron, then around to the next tooth, and finally ends up in the other rotor pole. This long path results in increased magnetic reluctance and loss of energy.

Axial flux motors, nevertheless, have a much reduced and direct flux path. The flux travels straight across the stator disc and rotor disc air gap. This configuration reduces energy loss and increases magnetic efficiency, allowing axial machines to have greater power densities and efficiencies—often over 96% in top-of-the-range applications.

In addition, the unidirectional flux path of axial machines enables the use of grain-oriented electrical steel, possessing much higher magnetic permeability and less core loss. Radial machines cannot apply this material because of the multi-directional flux flow. The result is that axial flux motors can be supplied with up to 2% increased efficiency, a valuable margin in electric powertrains and aeronautical applications.

[3]

[3]

Torque and Power Density

One of the most impressive benefits of axial flux motors is that they are very high in torque density. Because torque is proportional to rotor radius, those configurations involving axial flux—having intrinsically larger rotor diameters—are endowed with more torque for the same axial length. This renders them ideal for applications where there is little room but performance must not be compromised.

Radial motors are typically easier to manufacture and typically have lower torque density and larger overall length. They are best applied to applications in which space is available axially, like industrial motors, fans, and conveyor systems.

Cooling and Thermal Management

Cooling is one place where axial flux motors have a clear advantage. Windings of axial configurations are often placed near the outer surface of the motor, where they have direct thermal contact with very conductive materials like aluminum. This allows for more effective and space-saving cooling systems.

In radial flux motors, windings are buried more significantly into the stator, and heat must pass through the stator core—frequently steel, a less effective thermal conductor—before it can transfer to external cooling devices. This less direct route can limit performance, particularly at steady state high load conditions.

Winding Design and Copper Utilization

Axial flux motors also provide for more efficient winding configurations. The planar topology can fit shorter overhangs and a higher active-to-idle ratio of copper. More windings directly add to torque output, and the shorter end-turns reduce resistive loss and heat. Also, the disk-shaped stator configuration gives engineers the capability of adding turns per coil, boosting torque with no added heat production.

In radial configurations, longer end windings and curved slot topographies lead to greater copper loss and reduced efficiency in tight designs.

Manufacturing Complexity and Cost

Although having the technical advantages, axial flux motors are harder to manufacture. Their double-sided stators require more precise alignment, and the increased diameter brings about mechanical and structural challenges. Moreover, the value chain of axial flux motors is less mature, hence being expensive to manufacture, especially in large quantities.

Radial flux motors benefit from over one hundred years of industrial development. Their design is completely known, component vendors are widespread, and manufacturing techniques are highly sophisticated and cost-effective. This puts radial motors well ahead in the high-volume market where cost and economies of scale rule.

Applications and Market Trends

Radial flux motors are already an industry standard in electric vehicles used by Tesla, Volkswagen, GM, and the like. They are also common in industrial automation, home appliances, robots, and HVAC applications due to their reliability and integration ease.

Axial flux motors are gaining traction in high-end, high-performance applications. YASA Motors, which has now become a part of Mercedes-Benz, is designing axial flux machines for high-end electric supercars such as Ferrari SF90 Stradale and AMG One, where torque density, compactness, and weight reduction are paramount. Axial motors are ideal for eVTOL aircraft, drones, and mobile robotics, where space is constrained and grams count.

Summary Data Table

|

Aspect |

Axial Flux Motor |

Radial Flux Motor |

Comments / Use Case Examples |

|

Magnetic Flux Direction |

Parallel to the axis (axial) |

Perpendicular to the axis (radial) |

Determines overall geometry and torque density |

|

Shape |

Flat, disc-like |

Cylindrical |

Axial: pancake-style, Radial: classic cylindrical motor |

|

Torque Density |

High (up to 30–50% higher) |

Moderate to High |

Axial flux benefits from larger rotor diameter |

|

Power Density |

Higher (for short axial length) |

Slightly lower |

Important for compact applications |

|

Cooling Efficiency |

Better (shorter thermal path) |

Moderate |

Axial motors often have shorter thermal paths |

|

Efficiency |

>96% possible |

~90–95% typically |

Axial flux can reduce core and copper losses |

|

Motor Length |

Short |

Long |

Axial is compact along its axis |

|

Complexity of Manufacturing |

Higher (tight tolerances, double-sided stators) |

Lower |

Radial motors are widely manufactured |

|

Cost |

Often more expensive |

Cost-effective |

Radial flux motors benefit from mature supply chains |

|

Use in EVs |

Emerging (e.g., YASA motors in Ferrari, Mercedes) |

Dominant (Tesla, GM, VW, etc.) |

Radial motors are mainstream; axial used in high-performance EVs |

|

Best For |

High-torque, space-constrained designs |

General-purpose motors with established supply chains |

Axial: aerospace, high-performance EVs; Radial: industry standard |

For more information, please check Stanford Magnets.

Conclusion

Both axial and radial flux motors possess strong strengths. Radial flux motors are ideal for applications in contexts where existing technology, scalability, and cost are most critical. Axial flux motors' increased torque density, improved efficiency, and compact size make them ideal for future electric mobility, aerospace, and performance-centric systems.

As manufacturing, materials, and thermal management technologies develop, axial flux motors will play an increasing role in the electric propulsion future. However, radial motors will remain the backbone of traditional motor technology for the foreseeable future since they offer a balance of performance, cost, and reliability.

Reference:

[1] Habib, Asiful & Zainuri, Muhammad & Che, Hangseng & Ibrahim, Ahmad & Abd Rahim, Nasrudin & Alaas, Zuhair & Ahmed, Professor. (2022). A systematic review on current research and developments on coreless axial‐flux permanent‐magnet machines. IET Electric Power Applications. 16. n/a-n/a. 10.1049/elp2.12218.

[2] Dusane, Prathamesh. (2016). Simulation of BLDC Hub Motor in ANSYS - Maxwell. 10.13140/RG.2.1.2601.1764.

[3] Khan, Jahangir & Iqbal, M. Tariq & Quaicoe, John. (2006). Simplified Parameter Estimation Technique of Brushless DC Generators.