Choosing the Right Adhesive Magnet for Your Needs

Adhesive magnets are a versatile solution for various applications, from industrial use to household and DIY projects. Whether you need them for crafting, signage, or securing objects, selecting the right adhesive magnet is crucial for ensuring durability, effectiveness, and ease of use.

This article will discuss the key factors to consider when choosing an adhesive magnet, including material type, adhesive strength, size, and specific applications.

Introduction to Adhesive Magnets

Adhesive magnets are magnetic materials with a sticky backing that allows them to be attached to surfaces without additional glue or fasteners. They come in various shapes, sizes, and materials, each offering unique benefits depending on the intended use. The two primary components of adhesive magnets are the magnetic material and the adhesive backing.

Related reading: What Are Adhesive Magnets Used For?

Types of Magnetic Materials

The magnetic portion of adhesive magnets is typically made from one of the following materials:

- Flexible Magnetic Sheets and Strips

- Made from ferrite powder and rubber polymers, these are flexible and easy to cut.

- Ideal for lightweight applications like fridge magnets, signage, and craft projects.

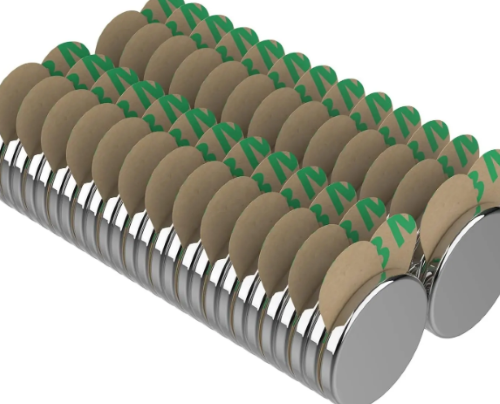

- Neodymium (Rare Earth) Magnets

- These are the strongest commercially available magnets.

- Ideal for applications requiring a strong hold, such as industrial and engineering uses.

- Often used in electronics, medical devices, and high-performance applications.

- Ceramic (Ferrite) Magnets

- More brittle but cost-effective and resistant to corrosion.

- Suitable for medium-strength applications like magnetic closures and educational tools.

Types of Adhesives Used in Adhesive Magnets

The adhesive backing is just as important as the magnet itself. The type of adhesive will determine how well the magnet sticks to different surfaces and how long it remains secure.

- Foam Tape Adhesive

- Provides a cushioned bond that works well on uneven surfaces.

- Ideal for mounting lightweight objects and craft applications.

- Acrylic-Based Adhesive

- Offers strong adhesion and durability.

- Suitable for outdoor and high-temperature applications.

- Rubber-Based Adhesive

- Flexible and easy to apply.

- Best for temporary applications and indoor use.

- 3M High-Performance Adhesive

- Premium adhesive with excellent durability and long-term holding power.

- Ideal for industrial, automotive, and high-strength applications.

Factors to Consider When Choosing an Adhesive Magnet

1. Application Purpose

- Determine whether you need the adhesive magnet for home, office, industrial, or commercial use.

- For light-duty applications like attaching papers to a refrigerator, a flexible magnetic strip will suffice.

- For heavy-duty applications, such as securing metal tools, a neodymium magnet with strong adhesive backing is required.

2. Surface Type

- Ensure the adhesive is compatible with the surface material (metal, plastic, glass, wood, etc.).

- Smooth surfaces require strong adhesives, while rough surfaces may benefit from foam-based adhesives.

3. Weight and Load Capacity

- Heavier objects require stronger magnets, such as neodymium magnets, with industrial-grade adhesive.

- Always check the weight rating before purchase.

4. Environmental Conditions

- If using outdoors, choose weather-resistant adhesive and corrosion-proof magnets.

- For high-temperature environments, use acrylic-based adhesives as they are heat-resistant.

5. Ease of Application and Removal

- Some adhesive magnets are permanent, while others allow for repositioning.

- Consider whether you need a temporary or long-term bond before selecting your adhesive magnet.

Common Uses for Adhesive Magnets

Adhesive magnets serve a wide range of functions across various industries and personal projects. Some common applications include:

- Crafting and DIY Projects: Create custom fridge magnets, magnetic labels, and decorative items.

- Signage and Displays: Secure posters, banners, and business signage without damaging surfaces.

- Home Organization: Attach lightweight tools, spice jars, or office supplies to metal surfaces.

- Automotive and Industrial Applications: Secure panels, trim pieces, and lightweight components.

- Educational and Office Use: Make magnetic learning aids, whiteboard accessories, and office organization tools.

Conclusion

Choosing the right adhesive magnet requires careful consideration of factors like magnetic material, adhesive type, intended use, and environmental conditions. By understanding the different options available, you can ensure a secure and lasting hold for your specific application.

Whether you're working on a DIY project, organizing your space, or implementing an industrial solution, selecting the best adhesive magnet will help you achieve your desired results with efficiency and reliability. For more information, please check Stanford Magnets.