Magnet Grades: A Deep Dive into Pull Force, Gauss, and N Numbers

Magnets play a crucial role in various industries and applications, from electronics to medical devices. However, understanding the nuances of magnet grades, pull force, and Gauss can be daunting. In this article, we will demystify these concepts and provide insights into choosing the right magnet grade for your specific needs.

-

Magnet Grades: What Are They and Why Do They Matter?

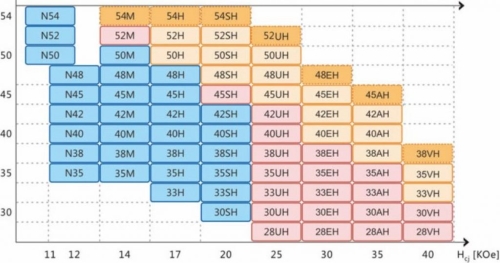

Magnet grades represent the strength and performance characteristics of a magnet. Commonly denoted by a letter (N, S, E, W) followed by a number, such as N35 or N52, these grades indicate the maximum energy product, a measure of magnetic strength. The higher the number, the stronger the magnet. For instance, an N52 magnet is stronger than an N35 magnet. The choice of grade depends on the specific application requirements, considering factors like temperature sensitivity and magnetic strength.

Related reading: Neodymium Magnet Grades

-

Pull Force: What Does It Mean?

Pull force, also known as magnetic strength or holding force, is the measure of how much weight a magnet can support when adhered to a flat, ferrous surface. It represents the force required to pull a magnet directly away from a flat, thick, and ground steel plate. Pull force is influenced by the grade, size, and shape of the magnet. Applications requiring a stronger hold or attachment benefit from higher pull force magnets. It is crucial to consider pull force when selecting a magnet for a particular application, ensuring it can withstand the required load.

-

How Many Gauss Is a Magnet?

Gauss is the unit of measurement for magnetic flux density. The higher the Gauss value, the stronger the magnetic field. When discussing magnets, Gauss is often used to quantify their strength. Understanding the Gauss rating is essential for applications where precise magnetic strength is critical.

-

Decoding N Numbers: Where Do They Come From?

The "N" in magnet grades stands for "Numerical." The number following the "N" represents the maximum energy product, which is a mathematical product of magnetism and magnet dimensions. For instance, an N52 magnet has a higher maximum energy product than an N35 magnet, indicating superior magnetic strength.

Here is a table illustrating the pull force and Gauss of standard neodymium magnets.

|

Shape & Size |

Gauss (Surface Field Streng -th) |

Pull Force (kg) |

|

|

N35 |

10mm x 3mm |

11700 |

1.5 |

|

N42 |

10mm x 3mm |

12800 |

2 |

|

N48 |

10mm x 3mm |

13600 |

2.5 |

|

N52 |

10mm x 3mm |

14500 |

3 |

|

N35 |

20mm x 3mm |

11700 |

3.6 |

|

N42 |

20mm x 3mm |

12800 |

4.5 |

|

N48 |

20mm x 3mm |

13600 |

5.5 |

|

N52 |

20mm x 3mm |

14500 |

6 |

Appendix: BH Curve - A Technical Insight

The BH Curve is a graphical representation of the relationship between magnetic flux density (B) and magnetic field strength (H) in a material. It provides valuable information about the magnetic properties of a material, helping engineers and researchers understand how a magnet will perform under different conditions. For more information and data, please check Stanford Magnets.

Neodymium Magnet Grades

Neodymium Magnet Grades

Understanding how neodymium magnet grades compare to other magnet types

Understanding how neodymium magnet grades compare to other magnet types involves exploring their characteristics in relation to ceramics, alnico, and samarium cobalt magnets.

Neodymium Magnets (NdFeB)

- Strength: Neodymium magnets boast the highest magnetic strength among commercially available magnets. Their exceptional power makes them ideal for applications where a strong magnetic field is crucial.

- Temperature Sensitivity: Neodymium magnets are sensitive to high temperatures and may experience a reduction in magnetic performance when exposed to elevated temperatures.

- Applications: Widely used in applications requiring strong, compact magnets, such as electric motors, headphones, and magnetic fasteners.

Ceramic Magnets (Ferrite)

- Strength: Ferrite magnets, while not as powerful as neodymium magnets, offer good magnetic strength for various applications.

- Temperature Sensitivity: Ferrite magnets exhibit excellent stability at high temperatures, making them suitable for applications involving elevated temperatures.

- Applications: Commonly used in motors, speakers, and refrigerator magnets due to their cost-effectiveness and adequate magnetic strength.

Alnico Magnets

- Strength: Alnico magnets provide strong magnetic fields and have good temperature stability.

- Temperature Sensitivity: Alnico magnets can withstand higher temperatures compared to neodymium magnets, making them suitable for high-temperature applications.

- Applications: Found in applications such as sensors, guitar pickups, and medical devices due to their combination of strength and temperature resistance.

Samarium Cobalt Magnets (SmCo)

- Strength: Samarium cobalt magnets exhibit high magnetic strength, second only to neodymium magnets.

- Temperature Sensitivity: SmCo magnets have excellent temperature stability and maintain their magnetic properties at elevated temperatures.

- Applications: Used in aerospace, medical devices, and high-temperature industrial applications where both strength and temperature resistance are critical.

Comparison summary

- Strength: Neodymium magnets lead in magnetic strength, followed closely by samarium cobalt magnets and alnico magnets. Ferrite magnets offer moderate strength.

- Temperature Sensitivity: Neodymium magnets are more sensitive to high temperatures, while alnico and samarium cobalt magnets demonstrate better temperature stability. Ferrite magnets also perform well in elevated temperatures.

- Applications: Neodymium magnets are favored in applications demanding maximum strength in a compact size. Ferrite magnets find use in cost-effective applications, while alnico and samarium cobalt magnets excel in specific high-temperature scenarios.

Related reading: Permanent Magnets Types, Pros & Cons

Conclusion: Choosing the Right Magnet Grade

Selecting the appropriate magnet grade is crucial for achieving optimal performance in your application. Consider factors such as pull force, Gauss rating, and the specific requirements of your project. Whether you're in the electronics industry or developing medical devices, understanding magnet grades is the key to harnessing the full potential of magnetic technology.

Remember, each magnet grade has its strengths and limitations, so take the time to assess your needs and choose accordingly. With this knowledge, you can navigate the world of magnets confidently and make informed decisions for your unique applications.