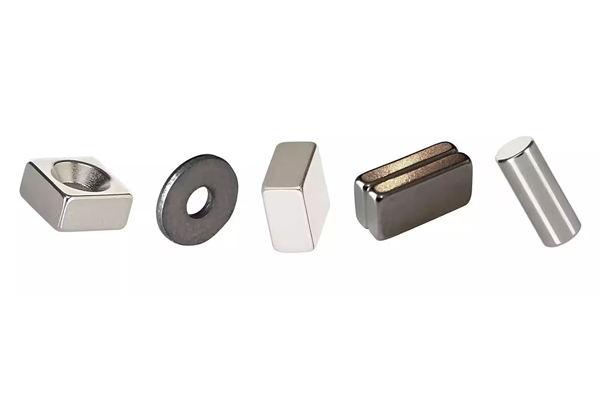

Protective Coatings/Surface Finish for Neodymium Magnets

A Neodymium magnet does not corrode and will retain its performance theoretically forever in a dry environment (if not subjected to excessive heat, radiation, or strong external magnetic fields). However, if it is placed in a wet environment, the result may be the opposite. The within-structure Iron can 'rust' and cause a permanent structural change in NdFeB, which will result in a permanent weakening of the magnetic performance; the worst-case scenario is a total loss of magnetism. Therefore, it is recommended to apply a coating on the magnet surface to protect the magnet from moisture (e.g. encasing, modified coatings such as zinc plus rubber, etc). The coating/surface finish should be for best corrosion protection; scratched or damaged surfaces may render the affected region more prone to corrosion. Marine environments (salt sprays, seawater) are particularly corrosive and far from ideal for NdFeB. It is the application and the overall design that determines how well the magnet will perform in damp environments.

Main Coating Types

| COATING APPLIED | NICKEL | EPOXY RESIN | Ni + EPOXY | |||

| Electroless | Powder Spray | E-Coating | Nickel plating | |||

| Coating | + Epoxy E-Coating | |||||

| Homogeneity | Excellent | Good | Poor | Excellent | Good | Good |

| Effectiveness Versus Magnet Size | Small (<20 grams) | Excellent | Good | Fair | Good | Good |

| Large (>20 grams) | Fair to Good | Good | Fair | Good | Good | |

| Hours before coating is likely to fail | Temp. & Humidity | >2500 | >500 | >1500 | >2500 | |

| (60°C, 95%RH) | ||||||

| Temp. & Humidity | >500 | >100 | >300 | >500 | ||

| (85°C, 85%RH) | ||||||

| Salt Spray | >48 | <24 | >100 | >200 | ||

| (35°C, 5% NaCl) | ||||||

| Coating Color | Silver | Silver | Black | Black | Black | |

| Heat Cycle | Fair | Fair | Fair | Fair | Fair | |

| Heat Resistance | Poor | Poor | Poor | Poor | Poor | |

| Collision Test | Fair | Fair | Fair | Fair | Fair | |

| Film to Material Adhesion test | Fair | Fair | Fair | Fair | Fair | |

| Glue Adhesion Test | Fair | Fair | Fair | Fair | Fair | |

| Tolerance Accuracy | Excellent | Excellent | Fair | Fair | Fair to Poor | |

| Additional Remarks | 15-30 microns Ni-Cu-Ni Standard coating | Epoxy resins are not hermetic | Thickness buildup can be a problem | |||