Rare-Earth Consumption: A Global Perspective

Introduction

In the ever-evolving landscape of modern technology and sustainable energy solutions, rare-earth elements (REEs) stand out as unsung heroes. These elements, often hidden within the devices and technologies that power our daily lives, are crucial for the advancement and efficiency of a wide array of applications.

From the robust magnets in wind turbines and electric vehicles (EVs) to the catalysts that reduce harmful emissions from cars, rare-earth elements are indispensable. Yet, as demand for these materials continues to surge, understanding the nuances of rare-earth consumption becomes essential for navigating future challenges and opportunities.

Trends in Production and Consumption

The lanthanide series, commonly referred to as rare-earth elements (REEs), are not as scarce as their name might suggest. Their abundance contrasts with their historical rarity in separation, owing to their similar chemical properties.

These elements are crucial in both established and emerging industries. In traditional sectors like catalysts, glass production, lighting, and metallurgy, lanthanum and cerium make up around 80% of the REEs utilized. Meanwhile, in burgeoning areas such as battery alloys, ceramics, and the creation of permanent magnets, Dysprosium, Neodymium, and Praseodymium represent approximately 8% of the REE consumption.

From 1990 to 2006, the global mining output of rare earth oxides (REOs) saw a swift annual increase of about 7%. Post-2008, this growth moderated, with a noticeable dip in 2007, attributed to global economic downturns. The expansion in REO production reflects a parallel rise in consumption, driven by both traditional uses (like automotive catalytic converters, glass and metallurgical processes, and phosphor for lighting) and the surge in demand from high-tech applications. These newer uses are primarily linked to the alternative energy sector, including batteries for hybrid vehicles, and to permanent magnets used in electric motors, stereo speakers, and wind turbines.

In 2008, global consumption of REOs reached 129,000 metric tons, as noted by Cordier and Hedrick (2010). Mature markets were responsible for about 60% of this figure, with the dynamic, rapidly growing sectors accounting for the remaining 40%, according to Bade (2010).

The consumption patterns of REEs vary significantly across different market sectors. Next, let’s have a more granular analysis of how these consumption trends manifest across various industries.

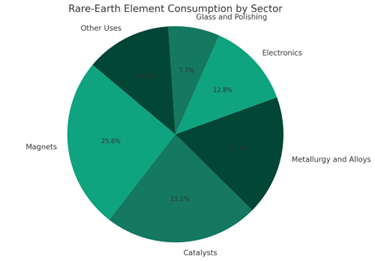

Overview of Rare-Earth Consumption by Sector:

As of the last update in April 2023, detailed and specific global consumption data for rare-earth elements (REEs) by sector or application can vary significantly, reflecting the dynamic nature of the market, technological advancements, and shifts in industrial demand.

1. Magnets (Neodymium, Praseodymium, Dysprosium, Terbium): Approximately 20-30%

- Permanent magnets represent the largest single use of rare-earth elements. These magnets are crucial for wind turbines, electric vehicles (EVs), hard disk drives, and various types of motors and generators.

2. Catalysts (Lanthanum, Cerium, Neodymium): Approximately 20-25%

- REEs are used as catalysts in petroleum refining and automotive catalytic converters to reduce emissions. Lanthanum and cerium are the primary elements used in these applications.

3. Metallurgy and Alloys (Cerium, Lanthanum, Neodymium): Approximately 15-20%

- Rare-earth elements are added to metals to improve their strength, workability, and resistance to corrosion. These alloys are used in the manufacturing of batteries, lightweight materials for aerospace and automotive industries, and in the production of specialty glasses.

4. Electronics (Various REEs): Approximately 10-15%

- REEs are used in the manufacturing of electronic components such as capacitors, fluorescent lamps, and displays. They are integral to the functionality of smartphones, computers, and other consumer electronics.

5. Glass and Polishing (Cerium, Lanthanum, Neodymium): Approximately 5-10%

- Rare earths are used in the production of glass, both for coloring and to produce special optical properties. Cerium, for example, is widely used in glass polishing applications.

6. Other Uses (Various REEs): Approximately 10-15%

- This category includes various applications such as phosphors for lighting and displays, ceramics, medical devices (e.g., MRI contrast agents), and military technology. The use of REEs in these applications is diverse and covers a wide range of specific elements.

In a word, Magnets and Catalysts are the leading sectors in rare-earth consumption, driven by the push for cleaner energy and more efficient vehicles. The sector diagram and table below clearly show how these critical elements are utilized.

Table 1. Rare-Earth Consumption by Sector

|

Sector |

REEs Used |

Consumption (%) |

Applications |

|

Magnets |

Neodymium, Praseodymium, Dysprosium, Terbium |

20-30% |

Wind turbines, EVs, hard disk drives, motors, and generators. |

|

Catalysts |

Lanthanum, Cerium, Neodymium |

20-25% |

Petroleum refining, automotive catalytic converters. |

|

Metallurgy and Alloys |

Cerium, Lanthanum, Neodymium |

15-20% |

Batteries, aerospace/auto materials, and specialty glasses. |

|

Electronics |

Various REEs |

10-15% |

Capacitors, lamps, displays, smartphones, and computers. |

|

Glass and Polishing |

Cerium, Lanthanum, Neodymium |

5-10% |

Glass coloring and polishing. |

|

Other Uses |

Various REEs |

10-15% |

Lighting and displays, ceramics, medical devices, and military technology. |

Global Dynamics and the Road Ahead

The consumption of rare-earth elements paints a picture of a world deeply reliant on these materials for technological progress and environmental stewardship. However, this reliance brings to light several critical considerations:

1. Supply Chain Vulnerabilities

The global supply of rare-earth elements is predominantly controlled by China, presenting significant vulnerabilities, including supply chain disruptions and geopolitical tensions. This concentration of supply underscores the need for diversifying sources and enhancing recycling efforts to ensure a stable and secure supply of REEs.

2. Sustainability and Environmental Impact

The extraction and processing of rare earths pose considerable environmental challenges, highlighting the importance of developing more sustainable practices. As the demand for these elements grows, propelled by the clean energy sector, the industry faces increasing pressure to minimize its environmental footprint.

3. Innovation and Recycling

Addressing the challenges associated with rare-earth consumption necessitates innovation and investment in recycling technologies. By prioritizing the efficient recovery of REEs from electronic waste and end-of-life products, the industry can reduce its reliance on primary sources and make strides toward a more circular economy.

Conclusion

As the world continues to advance technologically and seeks greener pathways for energy and industry, the role of rare-earth elements becomes ever more critical. Efforts by entities like Stanford Magnets highlight the industry's move towards sustainable sourcing of REEs. Balancing the growing demand with the need for environmental sustainability and supply chain resilience will require concerted efforts from governments, industries, and research institutions worldwide. Together, we are paving the way toward a future that is both sustainable and efficient with REEs and other advanced materials.

Reference:

[1] Rare-earth element. (2024, March 16). In Wikipedia. https://en.wikipedia.org/wiki/Rare-earth_element#