Selecting Different Shapes of Neodymium Magnets

Introduction

Neodymium magnets, known for their exceptional strength and versatility, come in various shapes and sizes to meet the demands of diverse applications. The shape of a neodymium magnet often determines its suitability for specific tasks. Let’s learn about the common shapes of neodymium magnets and their typical uses:

1. What are the common shapes of neodymium magnets?

Block (Rectangular) Magnets

Block magnets are shaped as rectangular or square prisms. Their large surface area and strong magnetic properties make them suitable for a variety of industrial uses.

Applications:

- Motors and Generators: Integral in the construction of electric motors and wind turbines.

- Holding and Mounting: Used in fixtures, jigs, and magnetic mounting systems.

- Automotive: Found in various sensors and electric vehicle motors.

Neodymium Disc Magnets

Neodymium disc magnets are circular and flat, available in various diameters and thicknesses. These magnets have a large pole area due to their wide, flat surface, which significantly increases their magnetic pull strength. The thickness of a neodymium disc magnet typically does not exceed its diameter, making it thin and effective for various applications.

Applications:

- Electronics: Used in speakers, headphones, and hard drives due to their compact size and strong magnetic field.

- Medical Devices: Essential in MRI machines and various medical instruments.

- Consumer Products: Common in magnetic fasteners for bags, jewelry, and clothing.

Cylinder (Rod) Magnets

Cylinder magnets have a cylindrical shape with a length greater than their diameter. This shape provides a focused magnetic field along the length of the cylinder.

Applications:

- Sensors and Actuators: Used in devices requiring precise magnetic fields.

- Industrial Applications: Employed in magnetic separators and lifting devices.

- Scientific Equipment: Utilized in mass spectrometers and electron microscopes.

Neodymium Ring Magnets

Neodymium ring magnets are donut-shaped, featuring a hole in the center. This design allows for a concentrated magnetic field around the ring.

Applications:

- Magnetic Couplings: Used in magnetic couplings for pumps and motors.

- Loudspeakers: Provide efficient magnetic fields for sound production.

- Scientific Applications: Employed in certain types of research equipment requiring specific magnetic configurations.

Neodymium Sphere Magnets

The magnet is spherical in shape, also known as a ball magnet. The polarity configuration of these magnets is similar to that of Earth, with higher concentrations of magnetic fields at the north and south poles. This design ensures that the magnetic strength is focused at these points, making spherical magnets particularly effective for educational and demonstration purposes.

Applications:

- Educational and Scientific Experiments: Used in demonstrations and experiments to illustrate magnetic fields.

- Novelty and Art Projects: Popular in magnetic toys and art installations for their unique shape and properties.

Custom Shapes

Custom-designed shapes tailored to specific industrial or scientific applications are also available. They find wide use in developing new technologies and innovative applications. Stanford Magnets specializes in supplying high-quality permanent magnets and magnetic products. We offer neodymium disc magnets, samarium cobalt magnets, alnico magnets, ceramic magnets, and magnetic assemblies. Customization of magnets based on client requirements and designs is also available. For more information, please check the homepage.

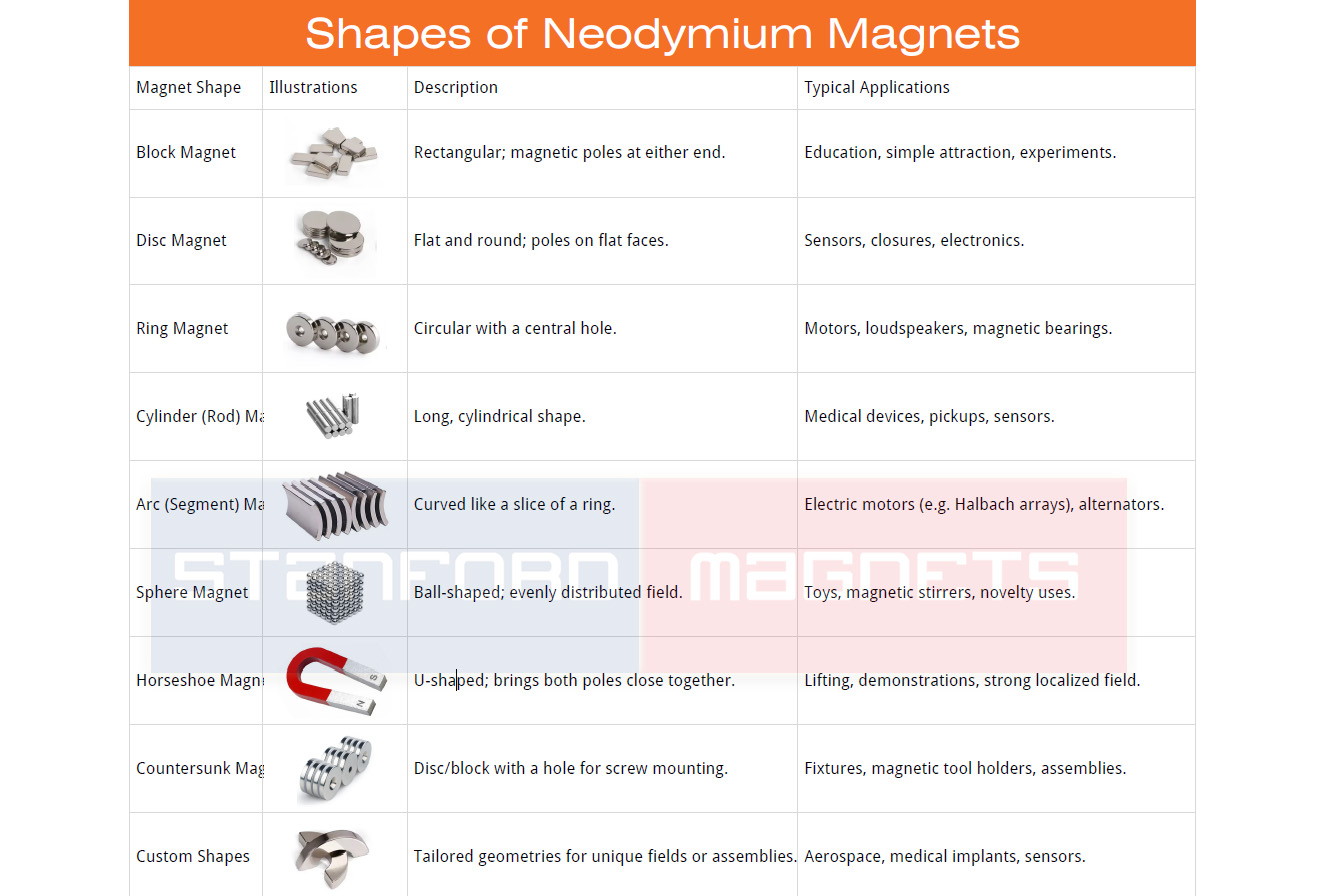

Table 1 Shapes of Neodymium Magnets

2. What factors should be considered when choosing the shape of a magnet?

- Application Requirements: Determine the specific magnetic field distribution and strength needed.

- Space Constraints: Choose a shape that fits within the design of the device or application.

- Magnetic Strength: Consider the strength required for the application and the shape that best provides it.

- Temperature Resistance: Ensure the shape and material can withstand the operating temperatures.

- Cost: Evaluate the cost-effectiveness of different shapes for the intended use.

Related reading: The Numerous Shapes of Neodymium Magnets

3. How are neodymium magnets manufactured in different shapes?

Neodymium magnets are manufactured through a process called sintering. This involves:

- Powder Preparation: Mixing neodymium, iron, and boron powders.

- Pressing: Compressing the powder into the desired shape.

- Sintering: Heating the compressed powder to form a solid magnet.

- Coating: Applying a protective layer to prevent corrosion and enhance durability.

- Machining: Further shaping and sizing through precise cutting and grinding.

4. What are some innovative uses of different magnet shapes?

Neodymium disc magnets are widely used in compact electronic devices and medical imaging equipment due to their strong magnetic pull and small size. Cylinder magnets are ideal for precision sensors and high-efficiency industrial machines, offering a focused magnetic field along their length. Block magnets are essential in powerful electric motors and renewable energy generators, providing a large surface area for high torque and efficient energy conversion. Ring magnets are crucial for magnetic couplings in high-performance pumps and motors, enabling efficient torque transfer with their concentrated magnetic field. Sphere magnets, or ball magnets, are popular in educational kits and creative sculptures, offering an omnidirectional magnetic field for demonstrations and artistic projects.

Conclusion

Neodymium magnets come in a variety of shapes, each tailored to optimize performance in specific applications. From neodymium disc magnets and cylinder magnets in electronic devices to arc and ring magnets in electric motors and scientific equipment, the shape of a neodymium magnet plays a crucial role in its functionality.

As technology continues to evolve, the demand for different shapes of neodymium magnets will continue to grow, driving advancements across multiple industries.