Advantages and Disadvantages of Axial Flux Motors

What is an Axial Flux Motor?

An axial flux motor is an electric motor where the magnetic flux is aligned parallel to the rotation axis, rather than radially. The design is other than the common radial flux motors. Axial flux motors have become increasingly well-liked because they are able to pack much power in small space, hence they are in high demand when space and efficiency are essential as in the cases of electric vehicles (EV), aerospace, among others.

Structure of an Axial Flux Motor

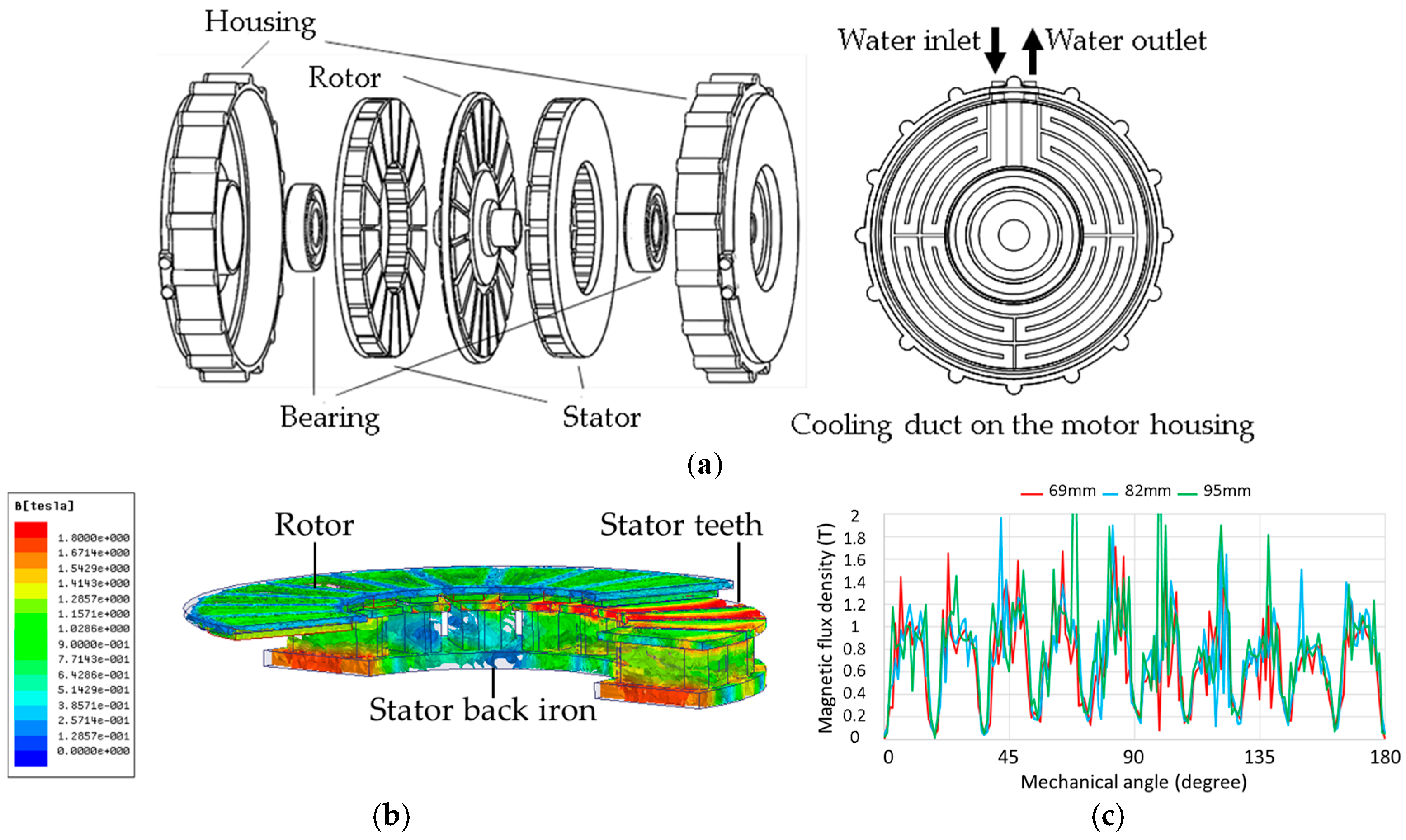

The internal structure of an axial flux motor varies. It can consist of:

• Disc-shaped rotors: Positioned on either side of a central stator, or vice versa.

• Stator: A flat, circular member packed with conductive wire coils.

• Permanent magnets: Mounted on the rotor discs.

• Air gap: A narrow gap between the rotors and stator that is extremely crucial in magnetic coupling.

This disk-shaped construction allows a more compact axial length and larger diameter, which all contribute towards a very high torque output from the motor.

Fig. 1 Structure of An Axial Flux Motor [1]

Working Mechanism of an Axial Flux Motor

Axial flux motors operate on the same basic principles as all other electric motors: when electric current flows through the stator windings, it induces a magnetic field. This field interacts with the magnetic field of the permanent magnets on the rotors, creating torque and causing the rotor to turn.

As the magnetic flux flows parallel to the axis of rotation, the resulting force is directed on the stator and rotor flat face, enabling greater torque production per volume and weight unit.

Further reading: An Overview of Axial Flux Motor: Benefits, Types, and Uses

Materials Used in Axial Flux Motors

To achieve optimal performance and efficiency, axial flux motors rely on carefully chosen materials. Copper is used in the stator windings due to its excellent electrical conductivity, which helps minimize resistive losses and improve overall efficiency. Laminated silicon steel is incorporated into the stator and rotor cores to reduce eddy current losses, enhancing magnetic performance and reducing heat buildup. High-strength neodymium-iron-boron (NdFeB) magnets are used in the rotor to generate strong magnetic fields, which are essential for producing high torque and power density. Additionally, composite materials are sometimes used in the motor’s structural components and housing. These materials help reduce overall weight while maintaining the mechanical strength needed for demanding applications.

Advantages of Axial Flux Motors

Axial flux motors offer several obvious advantages over traditional radial flux designs, including power density, structural efficiency, and design flexibility.

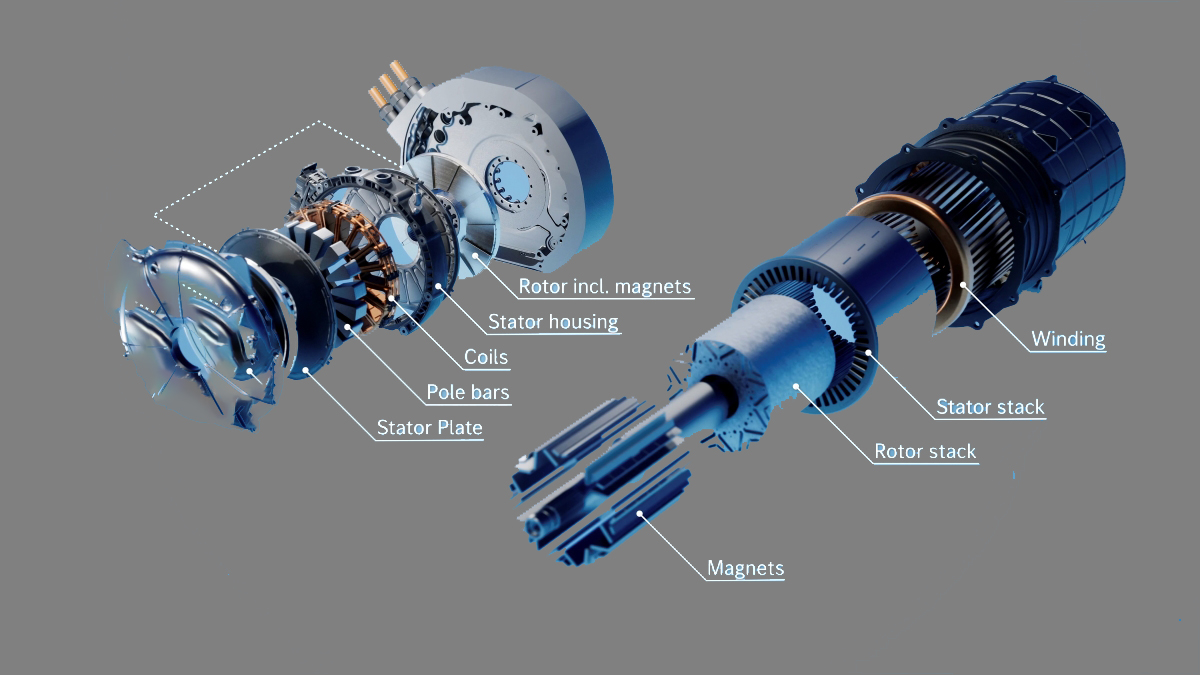

Fig. 2 Axial Flux Motor vs. Radial Flux Motor

Credit: YASA

1. Lightweight and Compact

Axial flux motors have a disc-like construction which significantly reduces their axial length—frequently to less than half that of a comparable radial flux motor. Though their outer diameter is identical, the reduced volume results in a motor over 50% smaller in size. As the core materials (copper and magnets) are similar, the overall weight is similarly decreased by about half. This lightweight construction not only saves space but also enhances the mechanical efficiency of the system, and hence axial motors are well-fitted for compact or mobile applications.

2. High Torque and Power Density

Due to their geometry, axial flux motors can deliver much higher torque per volume. Torque is proportional to force times radius, and the higher rotor diameter of axial flux motors provides them with an inbuilt advantage. In fact, torque density is up to four times greater than in similar-sized radial motors. Additionally, with the use of a stator design that does not include an iron yoke, power density can be two to three times greater than in conventional radial designs. The efficiency gains—typically 1% to 2% higher—make them especially suited for high-performance electric vehicles and aerospace applications.

3. Improved Winding Utilization

Axial flux motors commonly employ concentrated winding methods, which provide the best possible coil packing and least unused space. Radial motors commonly achieve approximately 50% use of coils, while axial can handle up to almost 100%, with a better electrical efficiency and better heat management.

4. Flexible Manufacturing and Design Freedom

The modular design of axial flux motors enables high production flexibility. Stator construction, magnetic pole topology, and winding strategies can be optimized for particular applications. This even carries over to system-level design: the motor's compact size enables new opportunities in electric vehicle structure, e.g., to locate a motor within each wheel to provide fine torque vectoring and improve handling capability.

Disadvantages of Axial Flux Motors

Despite their advantages, axial flux motors come with certain disadvantages:

•Manufacturing complexity: Their disk form requires proper alignment and high-precision manufacturing processes.

•Thermal challenges: Surface cooling is possible, but thermal management within requires a bit more complexity.

•Higher cost: Use of rare-earth magnets and high-performance materials drives the cost higher.

•Mechanical stress: The wide rotors may be prone to mechanical deformation with excessive loads.

Conclusion

Axial flux motors are a prime contender to supplant traditional radial designs, offering quantifiable advantages in torque density, weight reduction, power efficiency, and design flexibility. This article has highlighted some fact-based performance figures—such as up to 50% reduction in volume and weight, 1%–2% better efficiency, and torque densities up to four times radial motors—to underscore the engineering value of axial architectures. Due to these concrete advantages, axial flux motors are no longer theoretical upgrade; they're an actual application for generations to come of electric vehicles, aerospace machinery, and packaged drive systems when performance and optimization of the space are the only concerns. For more technical support, please check Stanford Magnets.

Reference:

[1] Yang, Y.P.; Shih, G.Y. Optimal Design of an Axial-Flux Permanent-Magnet Motor for an Electric Vehicle Based on Driving Scenarios. Energies 2016, 9, 285. https://doi.org/10.3390/en9040285