All You Need to Know about Permanent Magnet Rotors

Permanent magnet rotors are an essential part of modern electric motor technology for their enhanced efficiency and smaller sizes. This article provides an in-depth look into what permanent magnet rotors are, how they work, their advantages, and applications.

What Is a Permanent Magnet Rotor?

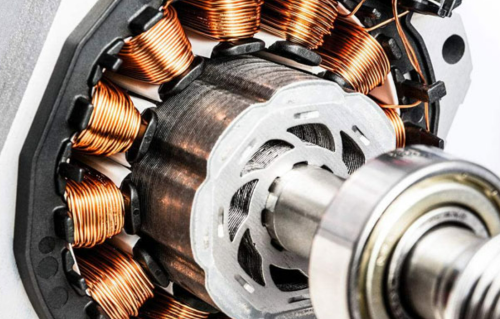

A permanent magnet rotor (PMA) is a rotating component of an electric motor or generator that uses permanent magnets to generate a magnetic field. Unlike conventional motors that rely on electromagnets or coils to create a magnetic field, permanent magnet rotors utilize the inherent magnetic properties of permanent magnets to generate the field required for motor operation. This design significantly reduces the complexity of the motor while improving efficiency.

How Does a Permanent Magnet Rotor Work?

Permanent magnet rotors function by harnessing the magnetic field created by the permanent magnets embedded in the rotor. In a synchronous motor, the rotor rotates at the same speed as the rotating magnetic field in the stator, which is powered by an AC current. As the rotor interacts with the magnetic field in the stator, torque is produced, which leads to the rotation of the motor’s shaft.

The key advantage of using permanent magnets is that they eliminate the need for external electrical power sources to generate the magnetic field in the rotor. This leads to a more efficient motor design, as there is no energy loss associated with generating the magnetic field via electricity. Instead, the magnetism of the permanent magnets provides a constant magnetic field, ensuring efficient motor operation over extended periods.

Further reading: Permanent Magnet Rotor vs. Induction Rotor: A Comparative Analysis in Electric Motor Technology

Types of Permanent Magnets Used in Rotors

The performance of permanent magnet rotors depends heavily on the type of magnets used in their design. Here are the primary types of permanent magnets employed:

- Neodymium-Iron-Boron (NdFeB) Magnets – Known for their high magnetic strength and efficiency, NdFeB magnets are widely used in EVs, industrial machinery, and renewable energy. However, they are costly and sensitive to temperature fluctuations.

- Samarium-Cobalt (SmCo) Magnets – Offering excellent high-temperature stability and corrosion resistance, SmCo magnets are ideal for aerospace and extreme-condition applications, though they are less powerful than NdFeB.

- Ferrite (Ceramic) Magnets – The most affordable option, ferrite magnets provide lower magnetic strength but are sufficient for household appliances and small motors.

Advantages of Permanent Magnet Rotors

Permanent magnet rotors offer several benefits over traditional rotor designs:

- High Efficiency – Permanent magnets eliminate energy losses from field generation, resulting in greater efficiency and lower power consumption.

- Compact & Lightweight – The absence of windings and external power sources enables smaller, lighter motors, ideal for EVs and space-constrained applications.

- Low Maintenance – Fewer moving parts reduce wear, extending lifespan and minimizing maintenance costs.

- High Torque Density – Delivers more torque per unit size, making it suitable for EVs and precision industrial machines.

- Eco-Friendly – Higher efficiency reduces energy use and emissions, while longevity minimizes waste.

Permanent Magnet Rotor vs. Induction Rotor

Permanent magnet rotors and induction rotors are two common types of rotors used in electric motors, each with distinct characteristics.

|

Feature |

Permanent Magnet Rotor |

Induction Rotor |

|

Working Principle |

Uses fixed permanent magnets. |

Relies on electromagnetic induction from the stator. |

|

Efficiency |

~95% |

~85% |

|

Torque Density |

High (2-3 Nm/kg) |

Moderate (1-2 Nm/kg) |

|

Power Factor |

Near unity (~0.98) |

Lower (~0.85) |

|

Size and Weight |

More compact and lightweight. |

Bulkier due to additional windings. |

|

Maintenance |

Low, as there are fewer moving parts. |

Higher, due to wear and tear on windings. |

|

Cost |

Higher. |

Lower. |

|

Temperature Sensitivity |

Sensitive to high temperatures. |

Performs better in high-temperature environments. |

|

Applications |

EVs, wind turbines, robotics, high-performance industrial machinery. |

Industrial motors, household appliances, HVAC systems. |

For more information and expertise, please check Stanford Magnets.

Applications of Permanent Magnet Rotors

Permanent magnet rotors are widely used across several industries, including:

- Electric Vehicles (EVs)

Permanent magnet rotors are crucial for the high efficiency and performance of electric vehicle motors. They contribute to longer driving ranges, faster acceleration, and more compact vehicle designs. - Wind Energy

Permanent magnet rotors are used in direct-drive generators for wind turbines. These systems are more efficient than traditional gear-based systems and reduce mechanical losses. - Industrial Automation and Robotics

In robotics, conveyor systems, and other industrial automation applications, permanent magnet rotors provide high precision and reliability, reducing energy consumption and improving overall performance. - Consumer Electronics

Small permanent magnet motors are employed in various consumer products like power tools, vacuum cleaners, and household appliances, where compact, efficient, and cost-effective motors are required.

Conclusion

Permanent magnet rotors represent a significant advancement in electric motor technology, offering improved efficiency, reduced size, and lower maintenance requirement. Their superior performance makes them an essential component in industries ranging from electric vehicles to renewable energy. As industries continue to prioritize energy efficiency and sustainability, the demand for permanent magnet rotors is expected to grow, shaping the future of modern technology.