How to Measure Magnet Strength?

The strength of a magnet is a critical property that determines its ability to attract or repel other materials. There are several ways to measure a magnet's strength, and the method depends on what aspect of the magnet’s strength is being evaluated. Let’s discuss these methods with some specific examples and data.

Magnet Strength and Measurements

1. Magnetic Field Strength (H)

Magnetic field strength measures the intensity of the magnetic field generated by a magnet. It is usually expressed in ampere-turns per meter (A/m) or oersteds (Oe). The stronger the magnetic field, the more powerful the magnet is.

Example: A typical neodymium magnet (NdFeB) might have a magnetic field strength around 1,000,000 A/m or about 12,500 Oe, while a common refrigerator magnet might have a field strength closer to 50 A/m (0.6 Oe).

Formula: H = I / l

Where:

- H is the magnetic field strength (in A/m or Oe),

- I is the current (in amperes),

- l is the length of the magnetic path (in meters).

2. Magnetic Flux Density (B)

Magnetic flux density, also known as magnetic induction, measures the amount of magnetic flux passing through a given area. It is measured in teslas (T) or gauss (G).

Example: A neodymium magnet can produce a magnetic flux density of around 1.4 T (14,000 G), while a refrigerator magnet typically generates only about 0.001 T (10 G).

Formula: B = Φ / A

Where:

- B is the magnetic flux density (in teslas or gauss),

- Φ is the magnetic flux (in webers),

- A is the area through which the flux passes (in square meters or square centimeters).

3. Coercivity (Hc)

Coercivity measures a magnet’s ability to resist being demagnetized. The higher the coercivity, the more stable the magnet’s magnetization. Coercivity is typically measured in oersteds (Oe) or amperes per meter (A/m).

Example:

- A neodymium magnet (N52 grade) can have a coercivity of >12,000 Oe.

- A ceramic magnet (e.g., ferrite) typically has a coercivity of 2,000–3,000 Oe.

- Alnico magnets usually have coercivity in the range of 2,000–5,000 Oe.

Higher coercivity is crucial for applications requiring magnets to maintain their magnetism over time, such as in motors or magnetic sensors.

4. Magnetic Moment (m)

The magnetic moment indicates the overall strength and orientation of the magnet’s magnetic field. It is measured in ampere-square meters (A·m²) or joules per tesla (J/T).

Example:

- A typical neodymium disc magnet (10 mm diameter × 5 mm height) with a magnetization of 1.3 T might have a magnetic moment of approximately 0.001 A·m².

- For a larger samarium-cobalt magnet (25 mm diameter × 10 mm height), the magnetic moment could be closer to 0.01 A·m².

Formula: m = M * V

Where:

- m is the magnetic moment (in A·m²),

- M is the magnetization (in A/m),

- V is the volume of the magnet (in cubic meters).

5. Pull Force

Pull force refers to the maximum force that can be applied to a magnet before it detaches from a ferromagnetic material (such as steel). This is commonly measured in pounds (lb) or newtons (N).

Example:

- A small neodymium magnet (10 mm diameter) can have a pull force of about 1 lb (4.45 N) on a flat steel surface.

- A large neodymium magnet (50 mm diameter) can produce a pull force of up to 300 lbs (1,334 N), making it suitable for industrial lifting applications.

Further reading: How Is the Pull Force of Magnets Determined?

6. Saturation Magnetization (Ms)

Saturation magnetization refers to the maximum magnetization a material can achieve. Beyond this point, no additional magnetization can occur, regardless of the applied magnetic field.

Example:

- A neodymium magnet can reach saturation magnetization values of around 1.2 × 10^6 A/m (1200 kA/m).

- Soft iron may have a saturation magnetization of 1.7 × 10^6 A/m, which is higher than many permanent magnets, but it lacks the ability to retain its magnetization after the external magnetic field is removed.

Magnet Strength and Illustrations

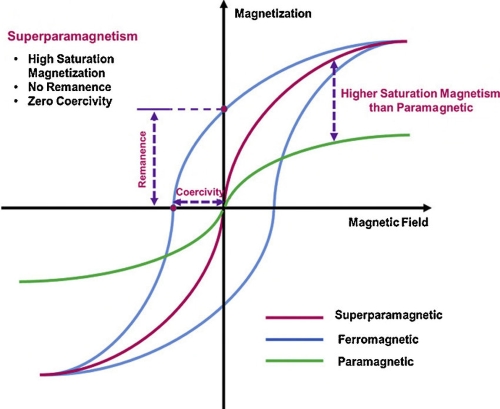

1. Hysteresis Curve

The hysteresis curve illustrates the relationship between the magnetization of a material and the applied magnetic field. It shows how the material’s magnetic properties change when a magnetic field is applied and then removed. The area within the curve represents the energy loss during magnetization and demagnetization cycles. Materials with high coercivity (like neodymium magnets) tend to have narrow loops, indicating strong resistance to demagnetization.

- A neodymium magnet will have a sharp and narrow hysteresis loop, showing high coercivity.

- A ferrite magnet will have a wider loop, indicating lower coercivity.

[1]

[1]

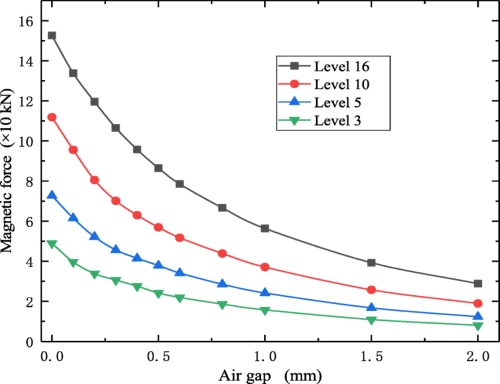

2. Pull Gap Curve

The pull gap curve demonstrates how the force a magnet can exert changes as the distance between the magnet and a ferromagnetic material increases. As the gap increases, the pull force decreases rapidly.

- The pull force from a neodymium magnet will decline more slowly over distance compared to a ceramic magnet, which will experience a sharper decrease in force with distance.

[2]

[2]

Conclusion

Measuring the strength of a magnet involves several parameters, such as magnetic field strength, magnetic flux density, coercivity, magnetic moment, pull force, and saturation magnetization. These measurements vary depending on the type of magnet and the specific application.

For example, neodymium magnets, with their high coercivity and flux density, are often used in high-performance applications, while ferrite magnets may be better suited for low-cost, lower-strength applications.

Reference:

[1] Mohammed, Leena & Gomaa, Hassan & Ragab, Doaa & Zhu, Jesse (Jingxu). (2016). Magnetic nanoparticles for environmental and biomedical applications: A review. Particuology. 30. 10.1016/j.partic.2016.06.001.

[2] Qin, Siji & Zhang, Hongsheng & Mao, Yaoben & Yang, Le & Li, Xianbin & Hu, Zonghui & Cheng, Xiao. (2020). Electropermanent magnet blank holder technique in sheet metal deep drawing. The International Journal of Advanced Manufacturing Technology. 106. 10.1007/s00170-020-05001-w.