How Many Shapes of Magnets Are There?

How many shapes of magnets are there? Well, this question is difficult to answer because permanent rare earth magnets are not standard products and they could come in all shapes and sizes according to a great variety of applications from customers.

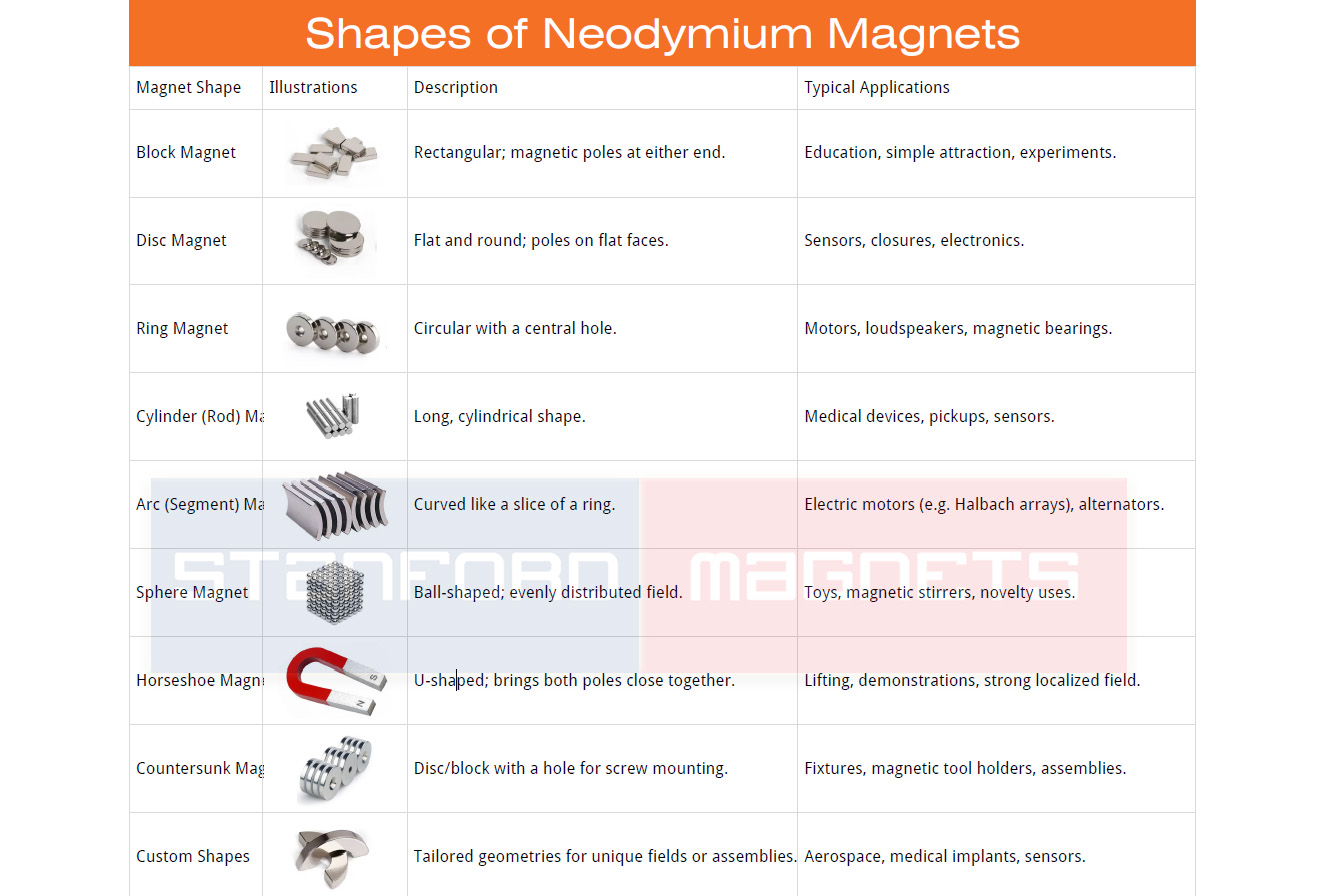

There are 10+ widely used magnet shapes, each serving different structural or magnetic field requirements. Some shapes are better for concentrated fields (horseshoe, arc), others for balanced fields (disc, ring), and many are designed for ease of integration (countersunk, block).

Shapes of Magnets

Some magnets are sintered into block or cylinder material and then through different machining methods as below, they can be made into the correct shape and size.

1. Wire-electrode cutting – to cut raw material from big into small, it is for curved face machining and big size plane

2. Slice – to cut raw material from big into small, it is in the direction of a plane

3. Surface grinding – to ground plane for high dimensional precision

4. Forming grinding – to process a curved face which has a high requirement for precision

5. Ultrasonic drilling – to process small hole

6. Chamfering – to process the sharp corner of the product into the round or bevel angle

7. CNC – to process a very complex magnet shape

8. Trepan boring – to process large hole

Custom Permanent Magnets

Some rare earth magnets are cast into a mold to get the specific magnet shape, but ultimately, they need grinding to achieve final dimensions.

They can be made into a bar, rectangle, block, horseshoes, round, rings, donuts, disc, segment, bread, multi-fingered rings, or other custom shapes.

Every shape of magnets is customized based on their application. If conditions allow, use the magnet as simply as possible, for using complex shape magnets will increase your cost.

The shapes of magnets determine how the magnetic field lines are arranged outside of the magnet, which also affects where the magnet can be used.

When it comes to the neodymium magnet, we will think of the horseshoe magnet immediately. Although in practical application, we hardly see it. It's still considered a symbol for a magnet and is used as a teaching tool nowadays.

Neodymium arc magnets, segment, or bread shape magnets are usually used on different motors because they can be fixed to a round rotor or stator.

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the shapes of magnets. If you want to know more about magnet shapes, we suggest you visit Stanford Magnets for more information.

Stanford Magnets is a leading supplier of magnet products across the world and has rich experience in the manufacture and sale of various magnets. It provides customers with high-quality rare earth permanent magnetic products like neodymium magnets and other non-rare earth permanent magnets at a very competitive price.