Magnetic Filtration: Effective Metal Removal for Industrial

Effective removal of metal impurities is key to equipment protection, product integrity, and process reliability. Magnetic filtration is a strong and reliable technology, especially suited to the extraction of ferrous particles from fluids such as oils, slurries, and powders. It is particularly important in industries where even minute metal particulate can cause excessive wear or mechanical damage to components.

What Is Magnetic Filtration?

Magnetic filtration is the removal of ferrous metal particles from liquids or bulk materials using magnetic fields. Magnetic filters differ from conventional filters that utilize physical media to physically strain out impurities since they possess the capability to filter out ultra-fine iron particles—most of which are too small to be removed by standard filters. This renders magnetic filtration particularly useful when applied in lubrication systems, process fluids, and sensitive equipment.

When microscopic metal particles enter engines, bearings, or gearboxes, they can accelerate wear and reduce the life of expensive equipment. Magnetic filtration removes the particles before they are recirculated, providing a second line of defense and ensuring equipment runs smoothly.

How Does Magnetic Filtration Work?

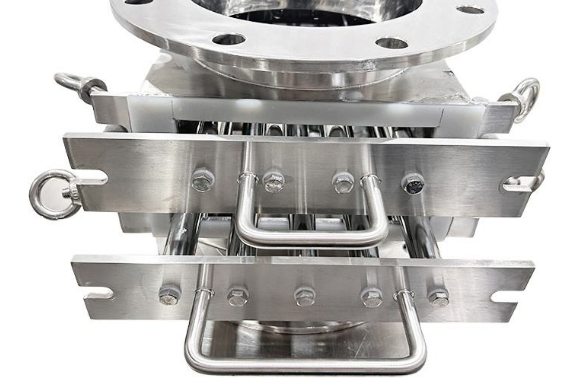

At the heart of a magnetic filter is a powerful magnetic component—a neodymium magnet in most instances—enclosed in a stainless steel housing. These magnetic bars or rods create high-intensity magnetic fields (typically above 12,000 gauss), strong enough to attract even sub-micron ferrous particles. The stainless steel enclosure, typically 304 or 316 grade, offers corrosion resistance and containment in harsh industrial environments.

Main Types of Magnetic Filtration Equipment

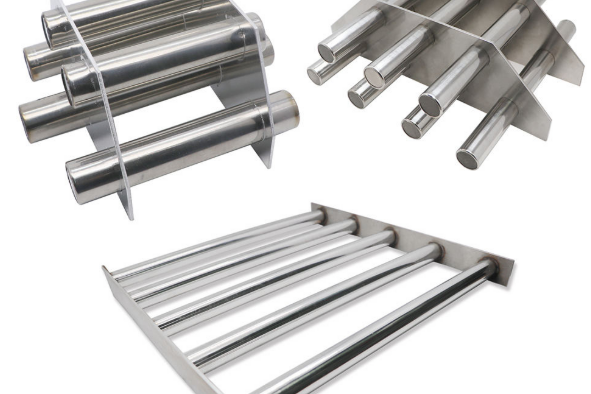

1. Magnetic Filter Bars

Magnetic filter bars are the most straightforward and most adaptable magnetic filtering elements. They are compact, easy to fit, and commonly used for the extraction of iron particles from free-flowing powders, slurries, and liquids. Each bar is sealed and waterproof, thus being rugged and hygienic for demanding applications.

2. Magnetic Grates

Also known as grate magnets or magnetic grids, magnetic grates consist of a number of magnetic filter bars in a grid-like housing. The construction provides maximum exposure to the flow of materials, thus they are highly efficient in capturing ferrous contaminants. Magnetic grates are often encased in durable stainless steel housing and may be installed in hoppers, chutes, or ducts where bulk materials are being handled.

3. Magnetic Drawers

Magnetic drawers are slide-out housings filled with a number of magnetic filter bars. The configuration allows easy access and cleaning with a high level of filtration performance. As the material flows through the drawer, the iron particles are captured on the magnetic bars' surface. These kinds of systems have wide applications in plastics, chemicals, and food industries.

Applications and Advantages of Magnetic Filtration

That magnetic filters can remove even minute metal particles makes them indispensable in the following industries:

- Machining and Lubrication Systems: Magnetic filters remove metal particles from oils and coolants, thus preventing bearing, gear, and cutting tool wear and increasing the life of machinery.

- Food Processing: Magnetic filters in food processing lines ensure product integrity and safety for consumers by trapping iron particles before they can contaminate the final product.

- Rubber and Plastics Industry: Magnetic filters safeguard molding and extrusion equipment by eliminating ferrous particles in raw materials, reducing maintenance and downtime.

- Chemical Processing and Powder Handling: Magnetic filters maintain powder and chemical compound integrity by extracting metallic contaminants, safeguarding both product and process equipment.

Key Benefits of Magnetic Filtration

Magnetic filtration has several key benefits.

It is able to strain out ultra-fine and even nano-sized metal particles that regular filters won't catch, leading to a higher level of cleanliness and protection.

The system is low-maintenance, does not require disposable filter media, and generates little operating cost and waste.

Magnetic filtration is also ideal for harsh environments, i.e., high-viscosity fluids or elevated temperatures. With its modular design, it is readily customisable and easily incorporated into any system.

Most importantly, through the continuous removal of harmful ferrous contaminants, magnetic filtration extends equipment life and significantly reduces the likelihood of unplanned downtime.

How to Choose Magnetic Filter Devices

The selection of proper magnetic filter bar depends on several key parameters:

- Magnetic Strength (Gauss rating): Determines the filtration efficiency

- Dimensions (Length and Diameter): Must fit the installation space and flow conditions

- Operating Temperature: Ensure magnets will not lose strength due to heat

- Housing Material: Typically 304 or 316 stainless steel, depending on corrosion resistance needs

- End Fittings: Threaded ends, flanges, or plain finishes are offered for easy mounting

Conclusion

Magnetic filtration systems come in various forms, each designed to effectively capture ferrous contaminants from powders, slurries, and liquids. The most common types include magnetic filter bars, magnetic grates, and magnetic drawers—all of which utilize high-strength magnets to ensure maximum separation efficiency.

Stanford Magnets has experience in designing and customizing magnetic filtration products to suit the particular needs of a wide range of industries. If ferrous contaminants are affecting your process, call us today to learn how our magnetic filtration products can be applied to optimize your performance and protect your equipment.