Magnetic Anisotropy And Anisotropic Materials

Introduction

Anisotropy in permanent magnets is the property that gives them a preferred direction of magnetization, enabling them to maintain stable magnetic fields in specific orientations. This characteristic, known as magnetic anisotropy, is key to the performance and stability of permanent magnets across applications, from electric motors to medical devices.

[1]

[1]

Types of Anisotropy in Permanent Magnets

- Crystalline Anisotropy: This is the dominant form of anisotropy in most permanent magnets. In materials like neodymium-iron-boron (NdFeB) and samarium-cobalt (SmCo), atoms are arranged in a crystal structure that favors magnetization in a specific direction. Aligning the magnetization along this "easy axis" allows the magnet to achieve maximum magnetic strength and stability. This is why these materials are “anisotropic magnets”—they perform optimally when magnetized in this preferred direction.

- Shape Anisotropy: Although crystalline anisotropy is primary, the shape of the magnet can also influence its anisotropy, particularly in smaller or elongated magnets. A magnet’s shape can guide the magnetic field alignment, helping reduce demagnetization and allowing for more targeted field configurations. This is particularly beneficial in custom-shaped magnets for specialized applications like sensors.

- Stress-Induced Anisotropy: Stresses in the magnet, from mechanical forces or even production processes, can also create slight anisotropy. This effect can influence the stability of the magnetic field, although it is generally secondary to crystalline anisotropy in permanent magnets.

Further reading: What is Magnetic Anisotropy?

Why Anisotropy Matters in Permanent Magnets

- Enhanced Magnetic Strength: The alignment of the magnetic domains along the easy axis of magnetization ensures maximum magnetic strength, essential in high-performance applications.

- Resistance to Demagnetization: Anisotropic permanent magnets are more resistant to external magnetic fields that might attempt to alter their magnetization. This resistance is critical in applications requiring long-lasting, stable magnetic fields.

- Tailored Magnetic Field Direction: For devices that need magnetic fields in specific directions, anisotropic magnets provide predictable and strong directional fields, which is particularly beneficial in motors, sensors, and medical devices.

Applications Benefiting from Anisotropic Permanent Magnets

- Electric Motors and Generators: Anisotropic NdFeB and SmCo magnets in motors enhance efficiency and torque due to their stable, high-strength magnetic fields.

- Medical Devices: In MRI machines and certain medical implants, stable anisotropic magnets provide precise and long-lasting magnetic fields.

- Data Storage: Hard drives and other data storage devices use anisotropic magnetic materials to maintain data integrity and density.

Conclusion

Magnetic anisotropy is fundamental in creating powerful, efficient, and reliable permanent magnets, allowing them to excel in demanding applications where directional stability and field strength are critical. For more permanent magnets, please check Stanford Magnets.

Reference:

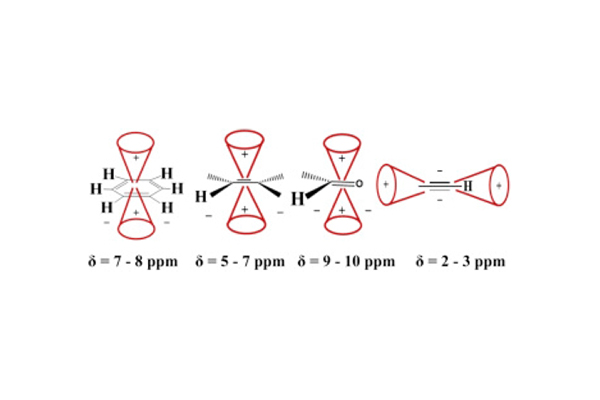

[1] Chandran Karunakaran, Paulraj Santharaman, Murugesan Balamurugan, Chapter Two - 1H and 13C Nuclear Magnetic Resonance Spectroscopy, Editor(s): Chandran Karunakaran, Spin Resonance Spectroscopy, Elsevier, 2018, Pages 49-110, ISBN 9780128136089, https://www.sciencedirect.com/science/article/pii/B9780128136089000022