An Introduction to Magnetic Filter

Magnetic filters are specialized devices designed to remove ferrous (magnetic) particles from liquids or gases in a wide range of applications. These filters use the power of magnets to capture and remove metal debris that can contaminate systems or affect the efficiency of processes. Magnetic filters are integral components in industries that rely on clean fluids for optimal performance, including manufacturing, automotive, food processing, and chemical industries.

What Is a Magnetic Filter?

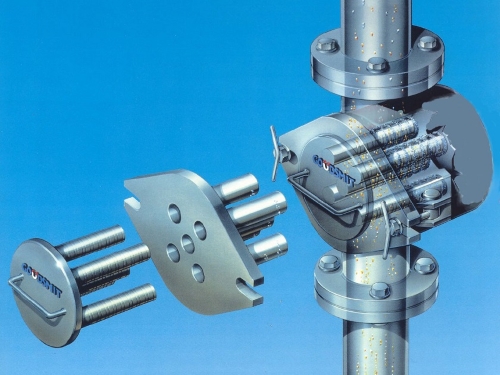

A magnetic filter is a filtration system that uses magnetic forces to attract and retain ferrous contaminants in liquids or gases. These filters typically consist of a magnetic core or magnetic rods housed within a filter casing. The magnetic rods create a powerful magnetic field that attracts and holds ferrous particles. The filtered fluid passes through the magnetic field and exits the filter without the metallic debris.

Magnetic filters are often custom-built to suit the specific needs of the application. They come in various designs, including inline, in-tank, and self-cleaning models, making them versatile for different industrial environments.

The key advantages of magnetic filters are numerous. First, they are highly effective at removing even the smallest ferrous particles, ensuring cleaner fluids and improved product quality. Additionally, magnetic filters are cost-effective because they help prevent damage to machinery and reduce the need for frequent maintenance, which in turn saves on repair and replacement costs. Another benefit is that magnetic filters are environmentally friendly. Unlike conventional filters, they do not produce waste or require chemical agents, making them a more sustainable option for businesses. Lastly, magnetic filters are low maintenance, particularly self-cleaning models, which need less upkeep compared to traditional filtration systems.

[1]

[1]

What Is Magnetic Filtration?

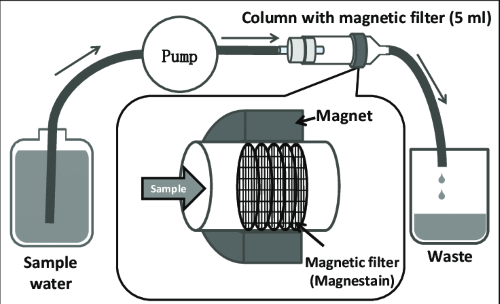

Magnetic filtration refers to the process of removing ferrous impurities from liquids or gases by using magnetic fields. This type of filtration works by placing a strong magnet in the flow path of the fluid or gas. As the fluid flows through the magnetic field, magnetic particles, such as iron, steel, or other ferrous materials, are attracted to the magnetic surface and trapped.

The process is highly effective at removing fine metal debris, such as rust, wear particles, and manufacturing debris, which could otherwise damage equipment or contaminate products. Unlike traditional filters that rely on physical barriers, magnetic filters provide a more efficient solution, particularly for capturing small or microscopic ferrous particles.

Applications and Advantages of Magnetic Filters

Magnetic filters are widely used in industries where contamination from ferrous particles is a concern. Their applications include:

- Manufacturing Industry: Magnetic filters are used to clean cutting fluids, coolants, and oils used in machinery. By removing metal particles generated during machining, magnetic filters prevent clogging and wear in equipment, reducing downtime and maintenance costs.

- Food Processing: Magnetic filters are essential in ensuring the cleanliness of food products. They are used to remove metal contaminants from ingredients and finished products, ensuring food safety and quality.

- Chemical and Pharmaceutical Industries: In these industries, the purity of fluids is critical. Magnetic filtration systems help to remove metal contaminants that could compromise the quality of products or lead to equipment malfunction.

- Automotive Industry: Magnetic filters are used to capture metal particles in lubrication systems, cooling systems, and fuel systems. This prevents wear and tear on engines and other automotive components.

- Water Treatment: Magnetic filters are increasingly used in water treatment plants to remove iron and other ferrous particles from water sources.

Maintenance and Cleaning

While magnetic filters are low-maintenance devices, periodic cleaning is essential to ensure their optimal performance. The frequency of cleaning depends on the level of contamination in the fluid and the type of system used.

In most systems, cleaning involves simply removing the magnetic rods or core, which will have accumulated ferrous particles. The particles are removed manually or with a cleaning tool designed for this purpose. Self-cleaning systems automatically discharge collected debris at regular intervals, reducing the need for human intervention.

Regular inspection of the filter for signs of wear or damage is also recommended. This ensures that the magnets remain powerful and that the filter is functioning as intended.

Strong Magnets for Magnetic Filters

The strength of the magnets used in magnetic filters plays a critical role in their effectiveness. High-quality magnets, such as neodymium, are commonly used for their strong magnetic properties. Neodymium magnets provide a high magnetic field intensity, making them capable of attracting even the finest metal particles. Other types of magnets, such as ceramic or ferrite magnets, are also used, depending on the specific application and cost considerations.

The selection of magnets depends on factors such as the type of contaminants, fluid flow rate, and environmental conditions. Stronger magnets allow for the removal of smaller ferrous particles, ensuring that the filtered liquid or gas meets stringent purity standards.

Conclusion

Magnetic filters are essential tools in various industries, offering an efficient and cost-effective solution for removing ferrous contaminants from liquids and gases. They provide a superior filtration method compared to traditional systems, ensuring cleaner fluids, reduced equipment wear, and better product quality. For more information, please check Stanford Magnets.

Reference:

[1] Wu, Haiyun & Sugata, Kobeni & Hirai, Mutsuko & Yoshiura, Yasutoshi & Hibi, Kyoko & Endo, Hideaki. (2017). Ultra highly sensitive method for detecting Edwardsiella ictaluri using high-gradient immunomagnetic separation with polymerase chain reaction. Sensing and Bio-Sensing Research. 16. 10.1016/j.sbsr.2017.11.003.