Rare Earth Permanent Magnet Motors

As early as the 1820s, the world's first motor appeared, and the rotor of this motor is a permanent magnet to generate an excitation magnetic field. However, the permanent magnet material used at that time was natural magnetite (Fe3O4), which had a very low magnetic energy density. The motor made from it was bulky and was soon replaced by an electric excitation motor.

With the development of technology, there have been many choices of permanent magnet materials. The motors using rare earth permanent magnet materials are also called rare earth permanent magnet motors.

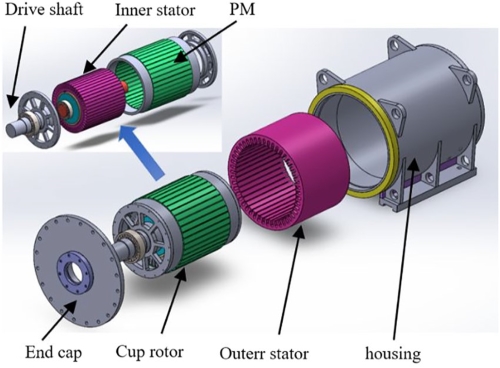

Fig. 1 Rare Earth Permanent Magnet Motors

The Structure of Rare Earth Permanent Magnet Motors

The rare earth permanent magnet synchronous motor is mainly composed of rotor, end cover, stator, and other components. Generally speaking, the stator structure of a permanent magnet synchronous motor is very similar to that of an ordinary induction motor, but the rotor of a permanent magnet synchronous motor has a unique structure.

[1]

[1]

Problems with Rare Earth Permanent Magnet Motors

1. Difficult to Adjust and Control the Magnetic Field

The permanent magnet motor can maintain its magnetic field after it is manufactured, but it also makes it extremely difficult to adjust and control its magnetic field from the outside. It is difficult for a permanent magnet generator to adjust its output voltage and power factor from the outside, and a permanent magnet DC motor can no longer adjust its speed by changing the excitation.

2. High in Price

As the current price of rare earth permanent magnets is still relatively expensive, the cost of rare earth permanent magnet motors is generally higher than that of electric excitation motors.

3. Demagnetization Problem

Rare earth permanent magnet motors have strict requirements for the working environment. When the temperature exceeds 180°C, some rare earth permanent magnet materials will experience irreversible demagnetization.

Moreover, they are prone to breakage under severe vibration or large temperature differences. Rare earth permanent magnet materials are easy to be oxidized and corroded, so it is best to perform surface treatment on them before use.

In addition, rare earth permanent magnet motors are very sensitive to overload. Once overloaded, permanent magnet materials will be demagnetized. At the same time, the electromagnetic load of the rare earth permanent magnet motor is very high, the magnetic field is difficult to adjust after being made, and its power control system is much more complicated than that of an induction motor.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the rare earth permanent magnet motors. If you want to learn more about magnets, we would like to advise you to visit Stanford Magnets for more information.

As a leading magnet supplier across the world, Stanford Magnets has been involved in R&D, manufacturing, and sales of magnets since the 1990s. It provides customers with high-quality permanent magnets like SmCo magnets, neodymium magnets, AlNiCo magnets, and ferrite magnets (ceramic magnets) at a very competitive price.

Reference:

[1] Zhang, Jiaxu & Zhang, Bingyi & Feng, Guihong. (2021). Research on rotor unbalance magnetic pull compensation method based on modular winding d‐axis current injection. IET Electric Power Applications. 16. 10.1049/elp2.12156.