Speaker Magnets: Types, Applications, and Comparison

Introduction

Speaker magnets play a critical role in loudspeakers, transforming electrical signals into audible sound through magnetic interactions. This article will introduce the various types of speaker magnets, their applications, and a detailed comparison between neodymium and ferrite magnets.

How Do Speaker Magnets Work?

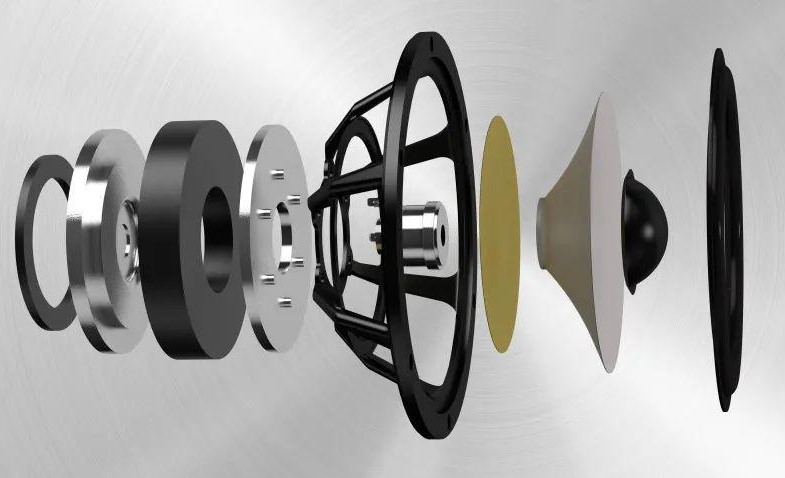

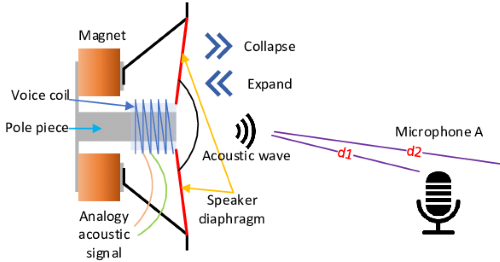

At the heart of a speaker is a component known as the voice coil, which is attached to a diaphragm (the cone). The voice coil is situated within the magnetic field created by the speaker magnet.

[1]

[1]

When an audio signal (an alternating current) passes through the voice coil, it generates a magnetic field that interacts with the field of the speaker magnet. This interaction causes the voice coil, and consequently the diaphragm, to move back and forth, producing sound waves.

The strength and precision of the speaker magnet directly influence the efficiency and quality of the sound produced.

4 Types of Speaker Magnets

1. Ferrite Magnets

Ferrite magnets, also known as ceramic magnets, are composed of iron oxide mixed with barium or strontium carbonate. They are relatively inexpensive and widely used due to their low cost and decent magnetic strength.

Ferrite magnets are commonly used in budget and mid-range audio equipment. You can find them in home theater systems, car speakers, and portable speakers.

2. Neodymium Magnets

Made from an alloy of neodymium, iron, and boron (NdFeB), these magnets are known for their exceptional magnetic strength and compact size.

Neodymium magnets are favored in high-end audio equipment. They are commonly used in professional-grade studio monitors, premium headphones, and compact speakers, where both performance and size are critical factors.

3. Alnico Magnets

Alnico magnets are composed of aluminum, nickel, cobalt, and iron. They were the standard in the audio industry before the advent of ferrite and neodymium magnets.

Alnico magnets remain popular in vintage and high-fidelity audio equipment. They are prized for their warm sound characteristics and are commonly used in guitar amplifiers and professional audio speakers.

4. Samarium Cobalt (SmCo) Magnets

These magnets are made from samarium and cobalt. They offer high magnetic strength and excellent temperature stability.

Samarium Cobalt (SmCo) magnets find common uses in specialized audio equipment that requires temperature resistance and high performance. These magnets are often found in military and aerospace audio systems.

Related reading: Types and Uses of Permanent Magnet

Neodymium Magnets vs. Ferrite Magnets: Comparing Speaker Magnets

--Magnetic Strength

- Neodymium magnets are significantly stronger than ferrite magnets. This allows for smaller and lighter speaker designs without compromising on performance. A neodymium magnet can produce a powerful magnetic field with less material, making it ideal for compact and portable audio devices.

- Ferrite magnets are less powerful, which means they need to be larger to achieve the same level of performance as neodymium magnets. This often results in bulkier speaker designs.

--Cost

- Nd magnets are more expensive due to the cost of raw materials and the manufacturing process. The higher cost is justified by the superior performance, making them a choice for premium audio equipment.

- Ferrite magnets are cheaper to produce, which makes them ideal for budget and mid-range audio products. Their affordability has made them the standard in many consumer audio applications.

--Weight and Size

- The high magnetic strength of neodymium magnets allows for smaller and lighter speakers. This is particularly advantageous in applications where space and weight are critical, such as in portable speakers and headphones.

- Ferrite magnets are heavier and bulkier, which can be a drawback in portable and compact audio devices. However, in stationary audio systems where weight and size are less of an issue, they are still widely used.

--Temperature Stability

- Nd magnets can lose their magnetic properties at high temperatures. To mitigate this, neodymium magnets often need to be coated or combined with other materials, which can add to the cost.

- Ferrite magnets exhibit excellent temperature stability and are less likely to lose their magnetic properties under high heat. This makes them suitable for applications in harsh environments.

Related reading: Maximum Operating Temperature VS. Curie Temperature

--Sound Quality

- Generally Nd provides a more dynamic and precise sound due to its high magnetic strength, which allows for better control over the voice coil movement. This results in clearer and more detailed audio reproduction.

- While they may not offer the same level of precision as neodymium magnets, ferrite magnets can still deliver good sound quality, particularly in mid-range and low-frequency applications. They provide a balanced performance that is suitable for most consumer audio products.

Conclusion

The choice between neodymium and ferrite speaker magnets ultimately depends on the specific needs and constraints of the audio application.

Neodymium magnets offer superior performance in terms of strength, size, and sound quality, making them ideal for high-end and portable audio devices. Ferrite magnets, on the other hand, provide a cost-effective solution with good performance and excellent temperature stability, making them suitable for a wide range of consumer audio products.

Understanding the characteristics and applications of each type of speaker magnet can help in selecting the right one for optimal audio performance. Hope that you can get the perfect magnet products on our website Stanford Magnets.

Reference:

[1] Chao, Cai & Pu, Henglin & Ye, Liyuan & Jiang, Hongbo & Luo, Jun. (2023). Active Acoustic Sensing for “Hearing” Temperature Under Acoustic Interference. IEEE Transactions on Mobile Computing. 22. 661-673. 10.1109/TMC.2021.3096792.