Types and Grades of Permanent Magnets

Introduction

Permanent magnets are materials that generate a persistent magnetic field without requiring an external power source. There are several types of permanent magnets, each with distinct compositions, advantages, and applications. Understanding these types and grades helps in choosing the right material for specific uses.

Types of Permanent Magnets

--Neodymium Magnets (NdFeB)

Neodymium magnets are composed of Neodymium (Nd), Iron (Fe), and Boron (B). They are known for having the highest magnetic strength among permanent magnets. These magnets offer excellent power-to-weight ratios, which makes them widely used in devices such as motors, hard drives, and headphones.

However, they are prone to corrosion unless properly coated, and their performance can degrade at high temperatures, with a maximum operating temperature range of around 80°C to 150°C.

--Samarium Cobalt Magnets (SmCo)

Samarium Cobalt magnets are made from a combination of Samarium (Sm) and Cobalt (Co). One of their standout features is their excellent resistance to high temperatures, able to withstand temperatures up to 300°C. These magnets also offer superior resistance to corrosion and oxidation, making them reliable for use in harsh environments. Additionally, they exhibit long-term magnetic stability.

On the downside, Samarium Cobalt magnets are more brittle and difficult to machine than Neodymium magnets, and they tend to be more expensive, which limits their use in cost-sensitive applications.

--Ferrite Magnets (Ceramic Magnets)

Ferrite magnets are primarily composed of iron oxide (Fe2O3) combined with barium (Ba) or strontium (Sr). These magnets are highly cost-effective and widely available, which makes them an economical choice for many industries. They also offer good resistance to corrosion, making them suitable for use in various environmental conditions.

While Ferrite magnets are effective at lower temperatures, they have a lower magnetic strength compared to rare-earth magnets like Neodymium and Samarium Cobalt. Additionally, they are brittle and can crack under stress, which limits their durability in certain applications.

--Alnico Magnets

Alnico magnets are made from a combination of Aluminum (Al), Nickel (Ni), and Cobalt (Co), with iron as the base material. They are known for their high resistance to corrosion, which makes them ideal for use in harsh environments. Alnico magnets also perform well at high temperatures, capable of withstanding temperatures up to 550°C. Their versatility in being magnetized into different shapes makes them useful in a wide range of applications.

However, their magnetic strength is lower compared to Neodymium and Samarium Cobalt magnets, and they are more expensive and difficult to process, which can increase production costs.

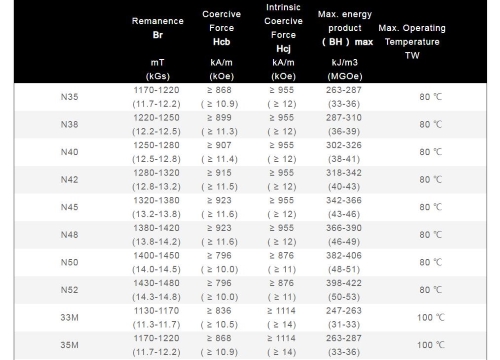

Common Grades of Neodymium Magnets

Neodymium magnets come in various grades that indicate their magnetic performance. These grades typically start with the letter "N," followed by a number and sometimes additional letters (e.g., N42). The number represents the magnet's maximum energy product, measured in Mega Gauss Oersteds (MGOe), while the letters indicate the magnet’s temperature tolerance.

- N-Series (N35, N38, N42, N52):

- The number indicates the magnetic strength (higher numbers = stronger magnets).

- Common Properties:

- N35: 35 MGOe, used in low-cost applications.

- N52: 52 MGOe, the strongest and most commonly used.

- N38-N50: Balanced options for general applications with medium strength.

- Letter Meaning (e.g., N, M, H, SH, UH, EH, AH):

- N: Standard temperature tolerance (80°C).

- M: 100°C maximum working temperature.

- H: 120°C maximum working temperature.

- SH: 150°C maximum working temperature.

- UH: 180°C maximum working temperature.

- EH: 200°C maximum working temperature.

- AH: 220°C maximum working temperature.

Common Grades of Samarium Cobalt Magnets

Samarium cobalt magnets are divided into different series based on their properties, with two main classifications: the 1:5 series and the 2:17 series.

--1:5 Series:

- Higher concentration of samarium, providing good magnetic strength.

- Typically used in high-temperature environments and in applications like motors and sensors.

- Properties:

- High resistance to demagnetization.

- Suitable for temperatures up to 250°C.

- Lower magnetic energy product compared to 2:17 series.

--2:17 Series:

- Higher energy product and magnetic strength than the 1:5 series.

- Typically used in more demanding applications.

- Properties:

- Excellent thermal stability, performing well at temperatures up to 300°C.

- Higher magnetic coercivity.

- Ideal for precision instruments, high-performance motors, and medical devices.

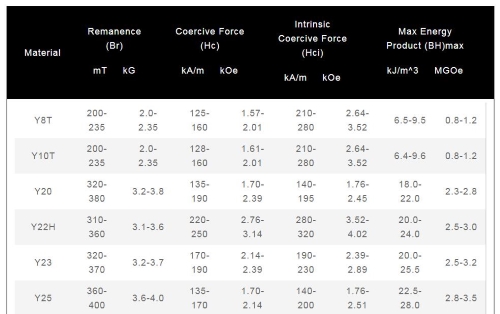

Grades of Ferrite Magnets

Ferrite magnets are available in different grades, often referred to by their coercivity and magnetic properties. Common ferrite magnet grades include: Y10, Y20, Y25, Y30, Y35. The number indicates the material’s magnetic strength, with higher numbers indicating stronger magnets.

- Y10 to Y30: Generally used for consumer products, low-end applications, and toys.

- Y35: Higher magnetic strength, often used in motors and industrial applications.

Grades of Alnico Magnets

Alnico magnets are classified by their composition and magnetic properties, often labeled with a combination of letters and numbers. These grades include:

- Grade 1: Basic Alnico, low magnetic strength.

- Grade 5: The most common grade, offering a balance of magnetic strength and temperature resistance.

- Grade 8: Higher strength for more demanding applications.

-Grade 9: The highest grade, with superior magnetic strength and performance at high temperatures.

Conclusion

The choice of permanent magnet depends on the specific requirements of the application, including magnetic strength, temperature stability, resistance to corrosion, and cost. Neodymium magnets offer the highest magnetic strength, while samarium cobalt magnets are ideal for high-temperature environments. Understanding the grades and properties of these magnets helps ensure the right magnet is selected for optimal performance and cost-effectiveness. For more information, please check Stanford Magnets.