Application of Neodymium Magnets in Motors

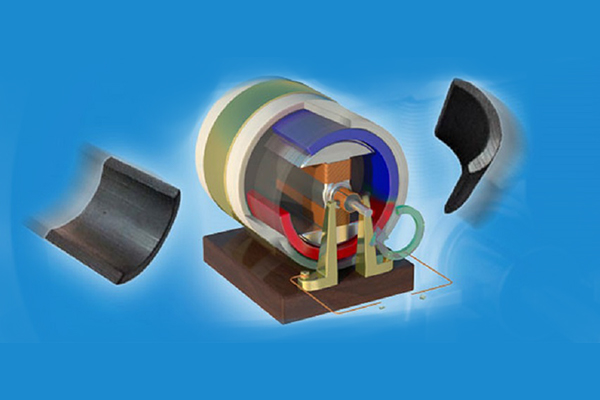

Neodymium magnet, also known as NdFeB magnet, is widely used in permanent magnet motors due to its excellent magnetic properties. In this article, let's take a closer look at the application of neodymium magnets in motors.

Application of Neodymium Magnets in Motors

Before diving into our article, let's figure out how many types of permanent magnet motors out there.

Common permanent magnet motors include permanent magnet DC motors and permanent magnet AC motors. Permanent magnet DC motors include brushed DC motors, brushless motors, and stepper motors, etc. Permanent magnet AC motors include synchronous permanent magnet motors, permanent magnet servo motors, and so on. Permanent magnet motors are also divided into permanent magnet linear motors and permanent magnet rotary motors according to their movement modes.

Because of the excellent magnetic properties of rare earth permanent magnet materials, a strong permanent magnetic field can be established without additional energy after magnetization. The rare earth permanent magnet motor, which is used to replace the traditional motor, is not only efficient but also simple in structure, reliable in operation, small in size, and light in weight.

It can not only achieve the high performance that traditional electric excitation motors can't match (such as ultra-high efficiency, ultra-high speed, ultra-high response speed), but also can be made into special motors that can meet specific operating requirements, such as elevator traction motors, automotive special motors, etc.

The combination of rare earth permanent magnet motor with power electronic technology and microcomputer control technology improves the performance of the motor and transmission system to a new level.

Application of Rare Earth Permanent Magnet Motors

1. Electric Vehicles (EVs)

-

Neodymium magnets are a critical component in the electric motors used in EVs, including hybrid and fully electric cars. They provide high torque at low speeds, enabling quick acceleration and improved energy efficiency. Their compact size also helps reduce the overall weight of the vehicle, extending its range.

2. Wind Turbines

-

Neodymium magnets are used in the generators of direct-drive wind turbines. They enable efficient energy conversion from wind to electricity, reducing the need for gearboxes and minimizing maintenance requirements.

3. Industrial Machinery

-

Neodymium magnets are used in motors for robotics, CNC machines, conveyor systems, and other industrial equipment. They provide precise control, high torque, and smooth operation, making them ideal for automation and high-performance applications.

4. Consumer Electronics

-

Neodymium magnets are found in the motors of hard drives, drones, electric tools, and household appliances. Their compact size and high efficiency make them ideal for devices where space and energy consumption are critical.

5. Aerospace and Defense

-

Neodymium magnets are used in motors for aircraft systems, satellites, and military equipment. Their lightweight and high-performance characteristics are essential for applications where weight and reliability are critical.

6. Medical Devices

-

Neodymium magnets are used in motors for medical equipment such as MRI machines, surgical tools, and prosthetics. Their high precision and reliability are crucial for medical applications where performance and safety are paramount.

Conclusion

Thank you for reading our article and we hope it can help you have a better understanding of the application of neodymium magnets in motors. If you want to learn more about neodymium magnets or other types of magnets, we would like to advise you to visit Stanford Magnets for more information.

As a leading magnet supplier across the world, Stanford Magnets has been involved in R&D, manufacturing, and sales of magnets since the 1990s. It provides customers with high-quality permanent magnets like SmCo magnets, neodymium magnets, AlNiCo magnets, and ferrite magnets (ceramic magnets) at a very competitive price.