Everything You Need to Know About Samarium Cobalt Magnets

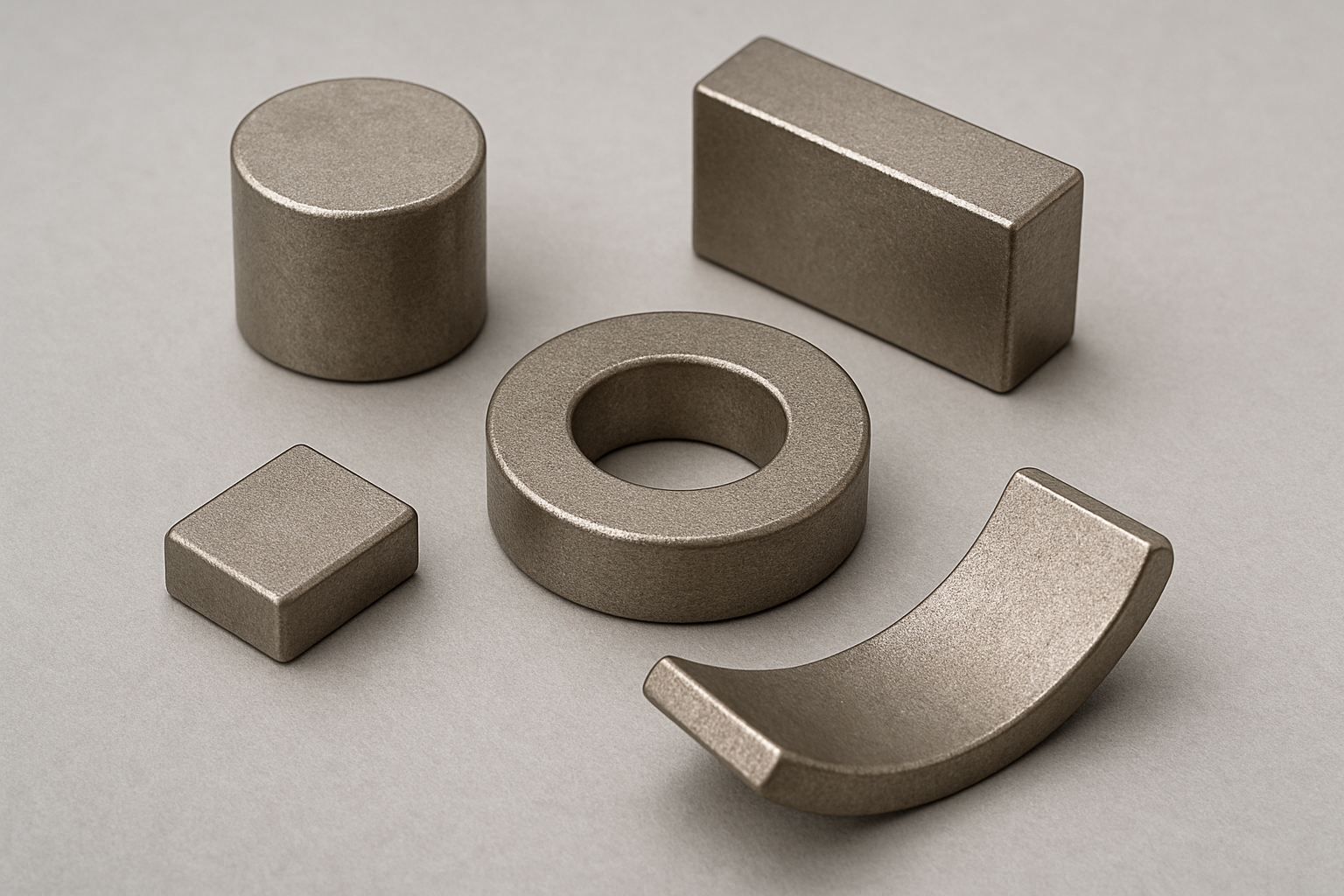

Samarium cobalt magnet is a type of rare-earth magnet mainly composed of samarium–cobalt alloys. A SmCo magnet may have a magnetic strength comparable to that of a NdFeB magnet but is higher in temperature rating and coercivity.

Samarium Cobalt Motor Magnets

Samarium Cobalt Motor Magnets

What are the characteristics of SmCo magnets?

Samarium Cobalt permanent magnets are known for their high magnetic strength, exceptional temperature stability, and reliable performance. As a result, they rarely require a coating to combat corrosion and therefore are more suitable for certain applications than Neodymium.

Samarium Cobalt magnets have the following characteristics:

• High resistance to demagnetization • High energy (magnetic strength is strong for its size) • Good temperature stability • Pricing for samarium cobalt is market-sensitive

SmCo magnets are often used when a wide range of operating temperatures is expected or if temperature effects must be mitigated, such as when high accuracy or highly stable performance is desired. A potential challenge is their propensity to chip and crack, due to their brittle nature.

What are the applications of the SmCo magnet?

Samarium cobalt magnets are often used in high-performance permanent magnet motors, medical instruments, magnetic couplings, magnetic bearings, gyroscopes, accelerometers, voice coil motors, particle accelerators, sputtering deposition, Halbach arrays, magnetic separation devices, speakers, microphones, undulators, wigglers, particle beam focusing devices, and many others.

Samarium Cobalt Magnets

Samarium Cobalt Magnets

What are the SmCo Magnets' Composition, Series, and Types?

Related: SmCo Magnet's Composition, Series, and Types

SmCo magnets are available in two series defined by the ratio of Samarium to Cobalt: Series 1-5 (SmCo5) and Series 2-17 (Sm2Co17).

SmCo5

These magnets are composed of Samarium-Cobalt alloys with a Sm-Co ratio of 1-5, that is to say, one atom of Samarium with five atoms of Cobalt. By weight, the Samarium would occupy 36% of the total. By weight, this samarium cobalt magnet alloy will typically contain 36% Samarium with a balance of Cobalt. This series of SmCo magnets can provide Max. Energy Product of 25 MGOe and has a reversible temperature coefficient of -0.05%/°C. In addition, this series is easier to calibrate to a specific magnetic field than the Sm2Co17 series.

Sm2Co17

This series is composed of Samarium-Cobalt alloys with a SmCo ratio of 2 to 17, that is to say, 2 Samarium atoms with 17 Cobalt atoms. It also contains other elements such as iron, copper, Zirconium, and Hafnium but in very small quantities. By weight, the Samarium occupies about 25% of the total.

Types

Currently, in the magnet market, two types of SmCo magnets are available: the bonded type and the sintered type.

Bonded SmCo Magnets

The bonded SmCo magnets are anisotropic ones manufactured with magnet powder held in place by epoxy resins or other special "binders". Energy products of the bonded magnet range from 5 MGOe to 15.1 MGOe.

Sintered SmCo Magnets

Sintered SmCo magnets are generally manufactured through this process: alloy milling to fine powder-powder pressed-magnetic fields applying-sintering in special furnace-grounding and shaping-coating.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the SmCo magnet. If you want to know more about samarium cobalt magnets and other magnet products, we advise you to visit Stanford Magnets for more information.

As one of the leading magnet product suppliers across the world, Stanford Magnets has been involved in R&D, manufacturing, and sales of permanent magnets since the 1990s. So we can provide our customers with high-quality rare earth permanent magnetic products like neodymium magnets, and other non-rare earth permanent magnets at an affordable price.