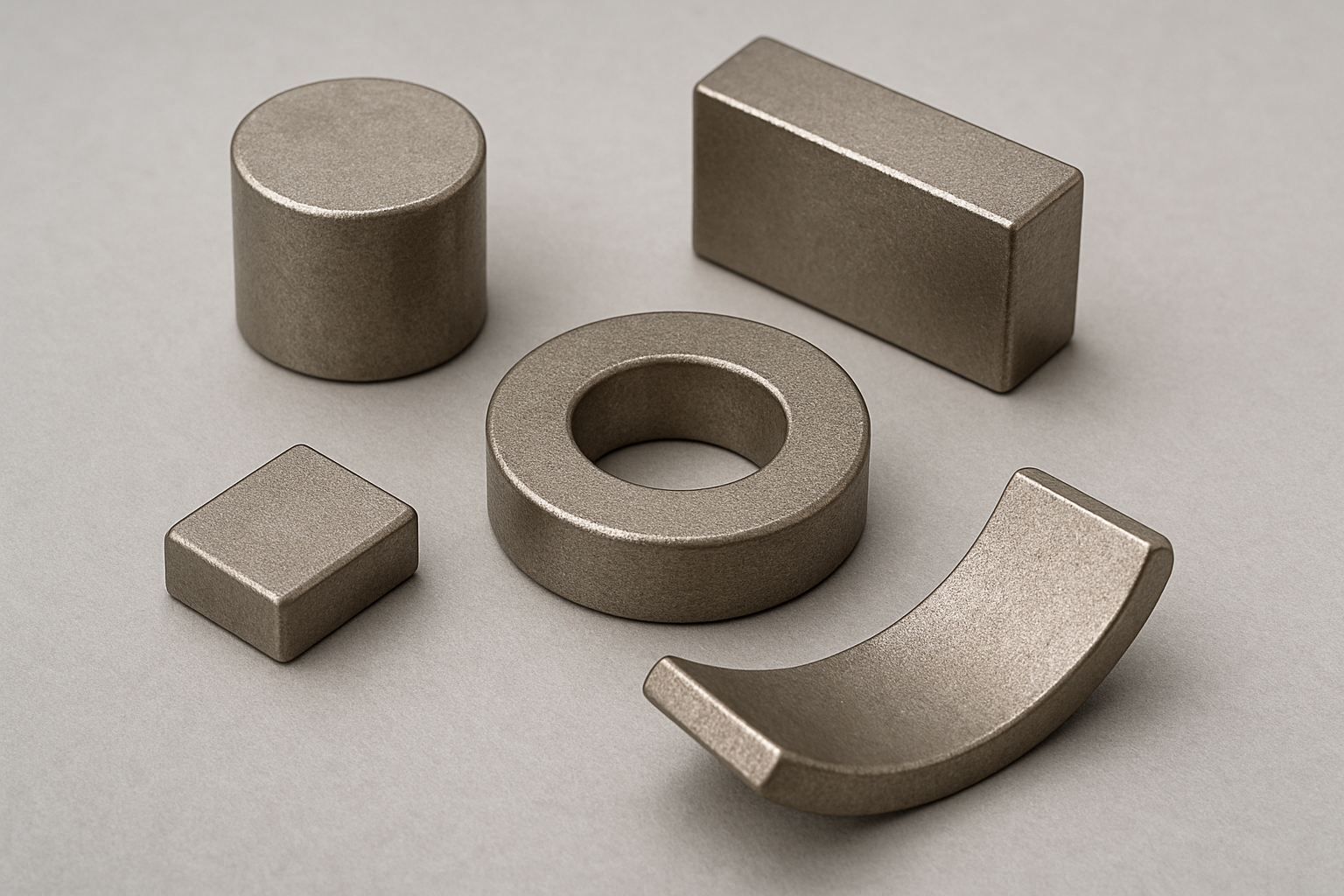

SmCo Magnet's Composition, Series and Types

Samarium cobalt magnet is a type of

rare-earth magnet mainly composed of

samarium–cobalt alloys. A

SmCo magnet may have a magnetic strength comparable to that of a

NdFeB magnet but is higher in temperature rating and coercivity.

SmCo magnets are available in two series defined by the ratio of Samarium to Cobalt: Series1-5 (SmCo5) and Series 2-17 (Sm2Co17). And there are currently in the magnet market two types of SmCo magnets are available: the bonded type and the sintered type.

SmCo5

SmCo5 magnets are composed of Samarium-Cobalt alloys with Sm-Co ratio of 1-5, that is to say, one atom of Samarium with five atoms of Cobalt. By weight, the Samarium would occupy 36% of the total. By weight, this samarium cobalt magnet alloy will typically contain 36% Samarium with the balance Cobalt. This series of

SmCo magnet is able to provide Max. Energy Product of 25 MGOe and has a reversible temperature coefficient of -0.05%/°C. In addition, this series is easier to calibrate to a specific magnetic field than the Sm

2Co

17 series.

Sm2Co17

Sm2Co17 magnet is composed of Samarium-Cobalt alloys with SmCo ratio of 2 to 17, that is to say, 2 Samarium atoms with 17 Cobalt atoms. It also contains other elements such as iron, copper, Zirconium, Hafnium but in very small quantities. By weight the Samarium occupies about 25% of the total. This type has a higher Max. Energy Product of 32 MGOe and a reversible temperature coefficient of -0.03%/°C.

Bonded SmCo magnets

The

bonded SmCo magnets are anisotropic ones manufactured with magnet powder held in place by epoxy resins or other special “binders”. Energy products of the bonded magnet range from 5 MGOe to 15.1 MGOe.

Sintered SmCo magnets

Sintered SmCo magnets are generally manufactured through this process: alloy milling to fine powder-powder pressed-magnetic fields applying-sintering in special furnace-grounding and shaping-coating.

Thank you for reading our article and we hope it can help you to have a better understanding of the

SmCo magnet. If you want to know more about

samarium cobalt magnets and other magnet products, we advise you to visit

Stanford Magnets for more information.

Follow Us On

About the author

Cathy Marchio

Cathy Marchio is an expert at Stanford Magnets, where she shares her deep knowledge of magnets like Neodymium and Samarium Cobalt. With a background in materials science, Cathy writes articles and guides that make complex topics easier to understand. She helps people learn about magnets and their uses in different industries, making her a key part of the company's success.

Reviews

{{viewsNumber}}

Thought On

"{{blogTitle}}"

LEVE A REPLY

(Cancle reply)

Your email address will not be published. Required fields are marked

*

{{item.children[0].name}}

{{item.children[0].created_at}}

{{item.children[0].content}}

More Replies

LEAVE A REPLY

Your email address will not be published. Required fields are

marked*