A Comprehensive Overview of Rare Earth Magnets

What Are Rare Earth Magnets?

--Introduction to Rare Earth Magnets

Rare earth magnets are powerful permanent magnets made from rare earth elements. These magnets exhibit exceptionally strong magnetic fields, making them indispensable in various applications, from industrial machinery to consumer electronics. The two primary types of rare earth magnets are neodymium magnets (NdFeB) and samarium cobalt magnets (SmCo), each possessing unique characteristics suited for specific applications.

Fig. 1 Rare Earth Magnets

--Are Rare Earth Magnets Really Rare?

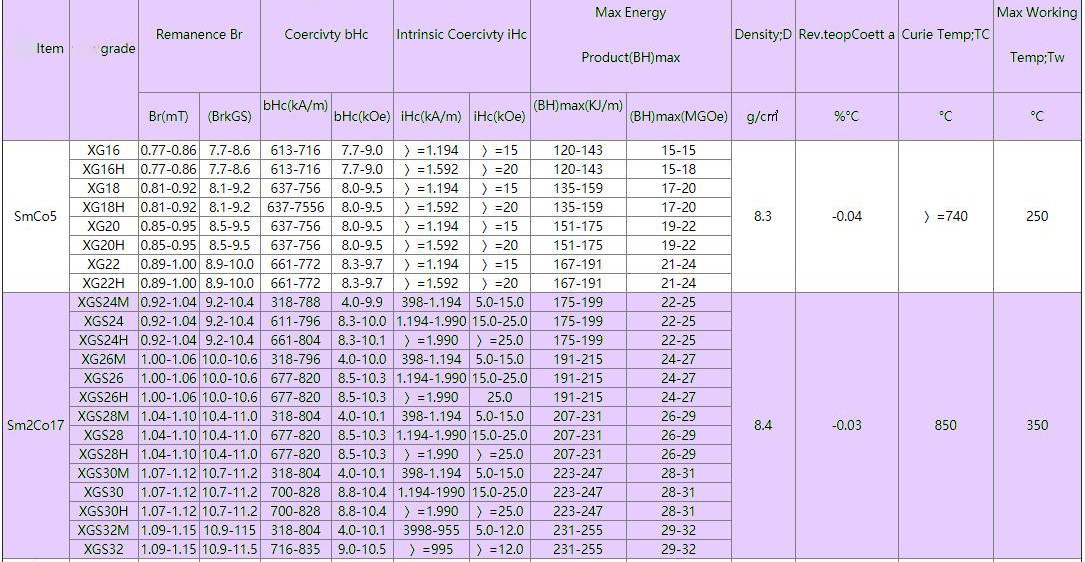

Despite their name, rare earth magnets are not particularly rare. The term "rare earth" refers to a set of 17 elements in the periodic table, including neodymium and samarium. These elements are relatively abundant in the Earth's crust; however, they are rarely found in concentrated, economically extractable deposits.

Further reading: Are Rare Earth Magnets Really “Rare”?

China currently dominates rare earth element mining and processing, controlling a significant portion of the global supply. This has led to supply chain concerns and efforts in other countries to develop alternative sources.

[1]

[1]

Fig. 2 Global distribution of rare earth element deposits and mines

--What Makes Rare Earth Magnets So Special?

Rare earth magnets are significantly stronger than conventional magnets due to their high magnetic energy density. They have superior resistance to demagnetization and can maintain their magnetic properties over extended periods. These characteristics make them ideal for high-performance applications.

Regular magnets, such as ferrite (ceramic) magnets, are much weaker and less durable than rare earth magnets. While ferrite magnets are inexpensive and suitable for everyday applications like refrigerator magnets and simple motors, rare earth magnets are essential for advanced applications like electric vehicles, wind turbines, and medical devices.

Here are a detailed comparison table listing the difference between rare earth magnets and regular magnets:

|

Feature |

Rare Earth Magnets |

Regular Magnets |

|

Composition |

Neodymium (NdFeB), Samarium Cobalt (SmCo) |

Ferrite (iron oxide), Alnico (Al-Ni-Co) |

|

Magnetic Strength |

Very high (up to 1.4 Tesla) |

Moderate to low (0.2–0.4 Tesla) |

|

Size for Same Strength |

Much smaller |

Larger for equivalent force |

|

Temperature Resistance |

SmCo: Excellent; NdFeB: Moderate |

Generally good (Ferrite up to ~250°C) |

|

Corrosion Resistance |

Poor (NdFeB) without coating |

Excellent (Ferrite); Alnico is also corrosion-resistant |

|

Cost |

High |

Low |

|

Demagnetization Resistance |

Excellent (especially SmCo) |

Fair to good (Alnico can demagnetize easily) |

|

Common Applications |

Motors, sensors, headphones, MRI, wind turbines |

Speakers, fridge magnets, toys, small motors |

The Two Most Common Rare Earth Magnets

--Neodymium Magnets and Samarium Cobalt Magnets

Neodymium magnets are the strongest type of permanent magnet available. They are composed of neodymium, iron, and boron (NdFeB) and are known for their impressive strength-to-weight ratio. However, they are susceptible to corrosion and lose strength at high temperatures.

Fig. 3 NdFeB Rare Earth Magnets

Samarium cobalt magnets, composed of samarium and cobalt (SmCo), are slightly weaker than neodymium magnets but have superior resistance to high temperatures and corrosion. This makes them ideal for aerospace, military, and high-temperature applications.

Fig. 4 SmCo Rare Earth Magnets

--Cons and Pros of These Two Rare Earth Magnets

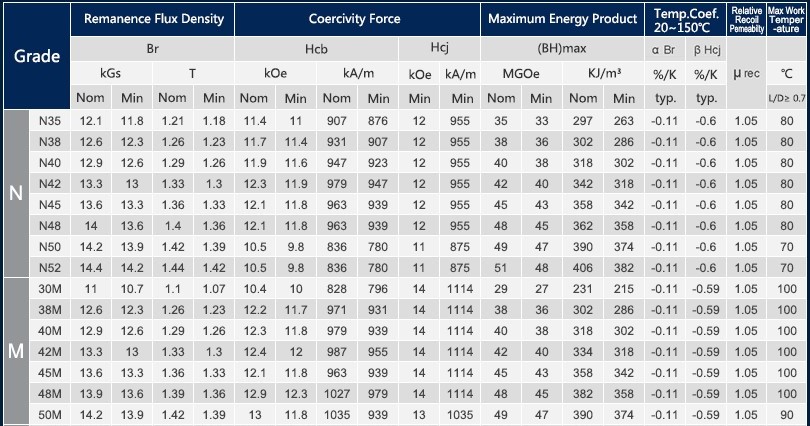

Neodymium magnets are composed primarily of neodymium, iron, and boron, forming an alloy with exceptional magnetic strength. They are the strongest commercially available permanent magnets, with a maximum energy product ranging from 35 to 52 MGOe.

However, they have a relatively low Curie temperature between 310 and 400°C, meaning they start losing magnetization at moderate heat levels unless specifically engineered for higher-temperature resistance. Another downside is their susceptibility to corrosion, necessitating protective coatings such as nickel or epoxy.

Samarium cobalt magnets, on the other hand, consist of samarium and cobalt. While they do not match the sheer strength of neodymium magnets, their maximum energy product still falls between 16 and 32 MGOe, making them significantly stronger than most other types of magnets.

The key advantage of samarium cobalt magnets is their high thermal stability, with a Curie temperature ranging from 700 to 850°C and an operating range extending up to 350°C. They also exhibit excellent corrosion resistance, eliminating the need for protective coatings.

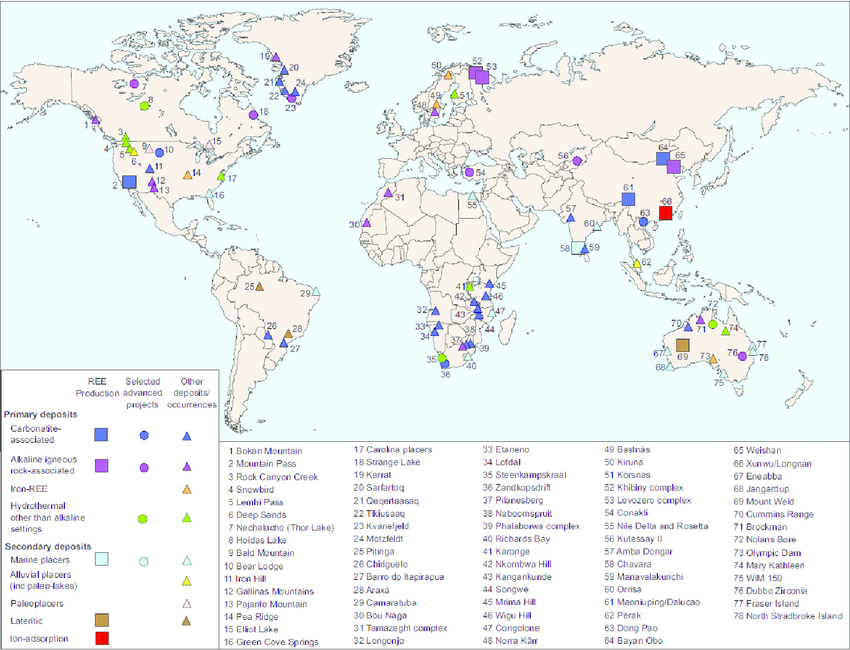

--Applications of Neodymium Magnets

Neodymium magnets have become integral to both everyday products and industrial applications. In consumer electronics, they are used in headphones, speakers, and magnetic clasps found in jewelry and bags. Their presence in household appliances extends to refrigerator magnets, magnetic phone mounts, and toys such as magnetic building blocks and fidget gadgets.

Industrially, neodymium magnets play a crucial role in electric motors and generators, particularly in electric vehicles and wind turbines, where their high magnetic strength contributes to energy efficiency.

They are also essential in medical technology, particularly in MRI machines and precision magnetic therapy devices.

Further reading: Key Uses of Neodymium-Iron-Boron (NdFeB) Magnets

[2]

[2]

Fig. 5 Applications of Neodymium Magnets

Additionally, they are used in hard disk drives for data storage and in magnetic levitation trains to reduce friction and enhance speed.

--Applications of Samarium Cobalt Magnets

While less common in everyday consumer products, samarium cobalt magnets are indispensable in industries requiring exceptional durability and thermal stability. They are commonly found in high-end mechanical watches, where their resistance to temperature fluctuations and corrosion ensures long-term reliability. Medical devices such as hearing aids also incorporate samarium cobalt magnets for their stability and compact size.

In industrial applications, these magnets are widely used in aerospace and defense technologies. They are crucial components in radar systems, satellite equipment, and missile guidance systems due to their resilience in extreme temperatures and harsh environments.

The oil and gas industry also relies on them in downhole sensors and drilling equipment exposed to high-pressure and high-temperature conditions.

Also, they are employed in the automotive industry, particularly in high-performance turbochargers and specialized electric motors that require stability under high thermal stress.

How to Choose: Neodymium and Samarium Cobalt Magnets

The decision between neodymium and samarium cobalt magnets depends on specific application needs.

- If magnetic strength is the primary concern and environmental conditions are moderate, neodymium magnets are the optimal choice due to their superior power and lower cost.

- However, if the application involves extreme temperatures, exposure to corrosive elements, or requires long-term stability, samarium cobalt magnets are the better option despite their higher price and lower magnetic strength.

For example, in electric vehicle motors, neodymium magnets are preferred because they provide the necessary torque and efficiency while being cost-effective. Conversely, in aerospace applications where weight reduction and thermal resistance are critical, samarium cobalt magnets outperform neodymium magnets in reliability and longevity.

Here’s a summary table comparing The Two Rare Earth Magnets:

|

Feature |

Neodymium (NdFeB) Magnets |

Samarium Cobalt (SmCo) Magnets |

|

Strength |

Strongest permanent magnet |

Slightly weaker than Neodymium |

|

Temperature Resistance |

Up to ~80-200°C (depends on grade) |

Up to ~250-350°C |

|

Corrosion Resistance |

Prone to corrosion, needs coating |

Highly corrosion-resistant |

|

Cost |

Lower cost |

More expensive |

|

Brittleness |

Brittle but less than SmCo |

Very brittle |

|

Applications |

Motors, electronics, medical devices |

Aerospace, high-temperature applications |

For more details, please check Stanford Magnets.

Safety and Handling of Rare Earth Magnets

- Rare earth magnets pose unique safety risks due to their extreme strength. If mishandled, they can snap together with great force, potentially causing injuries such as pinched fingers or broken skin.

- Because of their brittle nature, especially in the case of samarium cobalt magnets, improper handling can result in fragmentation, leading to sharp flying debris.

- Another significant hazard is the risk of accidental ingestion, particularly with small neodymium magnets. If swallowed, they can attract each other through intestinal walls, causing serious internal damage that requires immediate medical intervention. For this reason, products containing small rare earth magnets must be kept away from children.

- Additionally, rare earth magnets can interfere with electronic devices and medical implants such as pacemakers. Their strong magnetic fields can disrupt data on credit cards and hard drives if stored improperly. Safe storage practices include keeping them in separate compartments with adequate spacing and using protective barriers to prevent accidental attraction.

- Proper disposal of rare earth magnets is also essential. Due to their material composition, they should not be incinerated, as burning them can release harmful fumes. Many recycling facilities accept rare earth magnets, allowing for the recovery of valuable elements such as neodymium and samarium for reuse in new products.

Frequently Asked Questions

Q: How long do rare earth magnets last?

Rare earth magnets can retain their magnetism for decades under normal conditions. However, exposure to extreme temperatures or corrosion can lead to gradual demagnetization over time. Proper storage and protective coatings can extend their lifespan significantly.

Q: Can rare earth magnets be re-magnetized?

If a rare earth magnet loses its strength due to exposure to high temperatures or demagnetizing fields, it can often be re-magnetized using a powerful external magnetic field. However, physical damage or severe oxidation can permanently degrade its magnetic properties.

Q: Why are neodymium magnets coated?

Neodymium magnets are highly susceptible to oxidation, which can weaken their magnetic properties. Coatings such as nickel, gold, or epoxy provide a protective layer that prevents corrosion and enhances durability.

Q: Are samarium cobalt magnets worth the higher cost?

For applications requiring high-temperature resistance and corrosion immunity, samarium cobalt magnets are worth the investment. Their reliability in extreme environments justifies the higher price, particularly in aerospace, military, and industrial settings where failure is not an option.

Q: Can rare earth magnets break easily?

Yes, both neodymium and samarium cobalt magnets are brittle. While neodymium magnets are slightly tougher, both types can crack or shatter upon impact. Proper handling and storage precautions can minimize breakage risks.

Q: Do rare earth magnets pose environmental risks?

Mining and processing rare earth elements have environmental impacts, including habitat destruction and pollution. However, recycling rare earth magnets can help mitigate these effects by reducing the demand for new raw materials.

Reference:

[1] Barakos, George & Mischo, Helmut & Gutzmer, J.. (2015). Status Quo and Future Evaluations of Global Rare Earth Mining (with Respect to Special Rare Earth Element-industry Criteria).

[2] Mohapatra, Prajna & Li, Guomeng & Alagarsamy, Perumal & Xu, Xiandong. (2024). Advances in grain-boundary diffusion for high-performance permanent magnets. Materials Futures. 3. 10.1088/2752-5724/ad70ce.