Key Uses of Neodymium-Iron-Boron (NdFeB) Magnets

Neodymium-Iron-Boron (NdFeB) magnets—often simply referred to as rare earth magnets—represent a pivotal class of materials that have reshaped modern engineering and electronics. These magnets, known for their exceptional magnetic strength and compact size, are now indispensable in a wide array of applications. Let’s learn about how and where they are most critically used today, drawing insights from industry data and engineering trends.

[1]

[1]

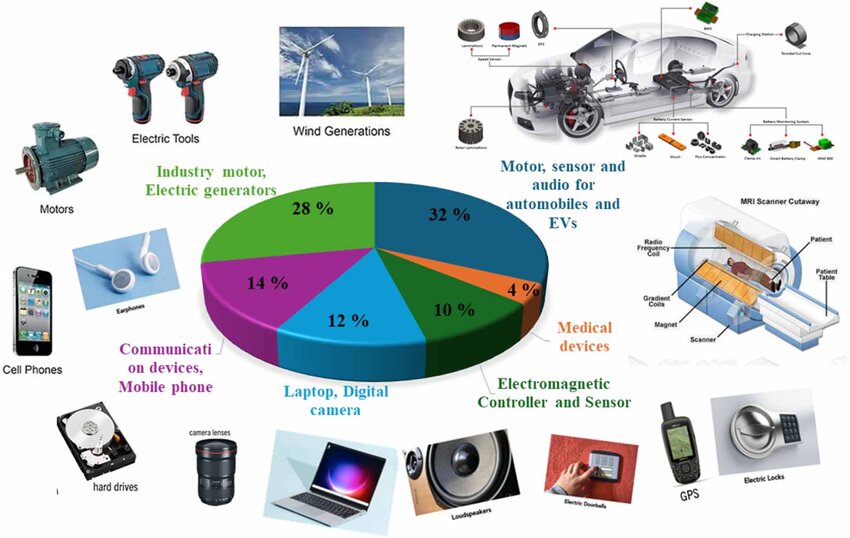

General Applications of NdFeB Magnets

From the smartphone in your pocket to the electric vehicle (EV) on the road, NdFeB magnets are at work behind the scenes. They are crucial components in:

- Wind turbines, especially offshore units

- Electric vehicle drive motors

- Hard disk drives

- Mobile phones and speakers

- Industrial motors and tools

- Electric bicycles and non-drive automotive systems

In many of these applications, the magnets are employed in permanent magnet motors. These motors offer distinct advantages: fewer maintenance requirements, higher power density, and greater energy efficiency—up to 2% more than high-efficiency induction motors in variable-speed scenarios.

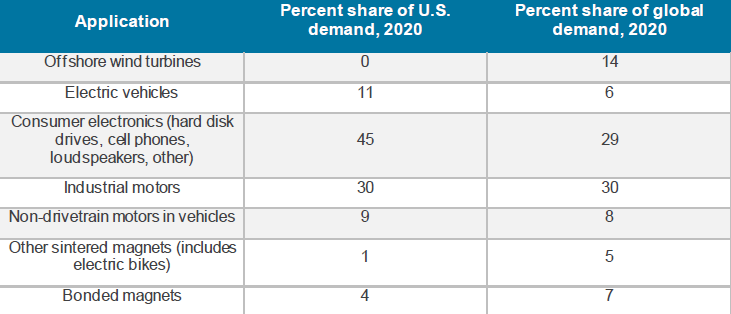

According to 2020 data, consumer electronics and industrial motors dominate NdFeB magnet demand, but wind power and automotive sectors are the fastest-growing segments. Different uses demand different grades of magnets. For example, high-temperature environments like EV motors require high coercivity grades (such as EH or AH), while low-temperature devices like hard drives or speakers typically use grades with minimal or no dysprosium content.

[2]

The Wind Energy Revolution

In the renewable energy landscape, wind turbines—particularly offshore installations—rely increasingly on Permanent Magnet Synchronous Generators (PMSGs). These are often called direct-drive generators, and unlike traditional designs, they eliminate the need for gearboxes. That means fewer moving parts, less maintenance, and more efficiency—key factors in harsh marine environments.

Each megawatt (MW) of installed capacity typically incorporates 2.7 to 3.2 metric tons of NdFeB magnets, often of SH grade. Although other generator types (like double-fed induction generators or externally excited synchronous generators) do not use rare earth magnets, PMSGs are steadily gaining traction due to their superior performance and reliability.

NdFeB Magnets in Electric Vehicles

Electric vehicles are perhaps the most transformative application of NdFeB magnets. The heart of the EV drivetrain—the synchronous traction motor—often depends on these powerful magnets. They enable:

- High torque at low RPMs

- Compact and lightweight motor design

- High energy efficiency without the need for external excitation systems

By 2025, it’s projected that 90% to 100% of battery-electric and hybrid vehicles will use motors equipped with NdFeB magnets. Each vehicle typically consumes 1–2 kilograms of these magnets just in the drive motor.

Moreover, NdFeB magnets find use in several secondary vehicle systems—speakers, sensors, transmissions, and electronic steering—though these contribute relatively little to the overall magnet demand compared to the traction motor.

A Material for a Modern World

NdFeB magnets exemplify the perfect marriage between material science and mechanical innovation. Their role in clean energy and high-efficiency transportation marks them as essential for a sustainable technological future.

At Stanford Magnets, we specialize in providing NdFeB magnets tailored to specific application demands—whether it’s high-temperature stability for EVs or optimized power-to-weight ratios for offshore wind turbines. Our expertise ensures that engineers and manufacturers receive reliable, application-specific solutions every time.

Reference:

[1] Mohapatra, Prajna & Li, Guomeng & Alagarsamy, Perumal & Xu, Xiandong. (2024). Advances in grain-boundary diffusion for high-performance permanent magnets. Materials Futures. 3. 10.1088/2752-5724/ad70ce.

[2] U. D. O. E. (2022, January 24). Rare Earth Permanent Magnets: Supply Chain Deep Dive Assessment. U.S. Department of Energy. Retrieved May 8, 2025, from https://www.energy.gov/sites/default/files/2024-12/Neodymium%2520Magnets%2520Supply%2520Chain%2520Report%2520-%2520Final%5B1%5D.pdf