How to Choose between Samarium Cobalt Magnets and Neodymium Magnets?

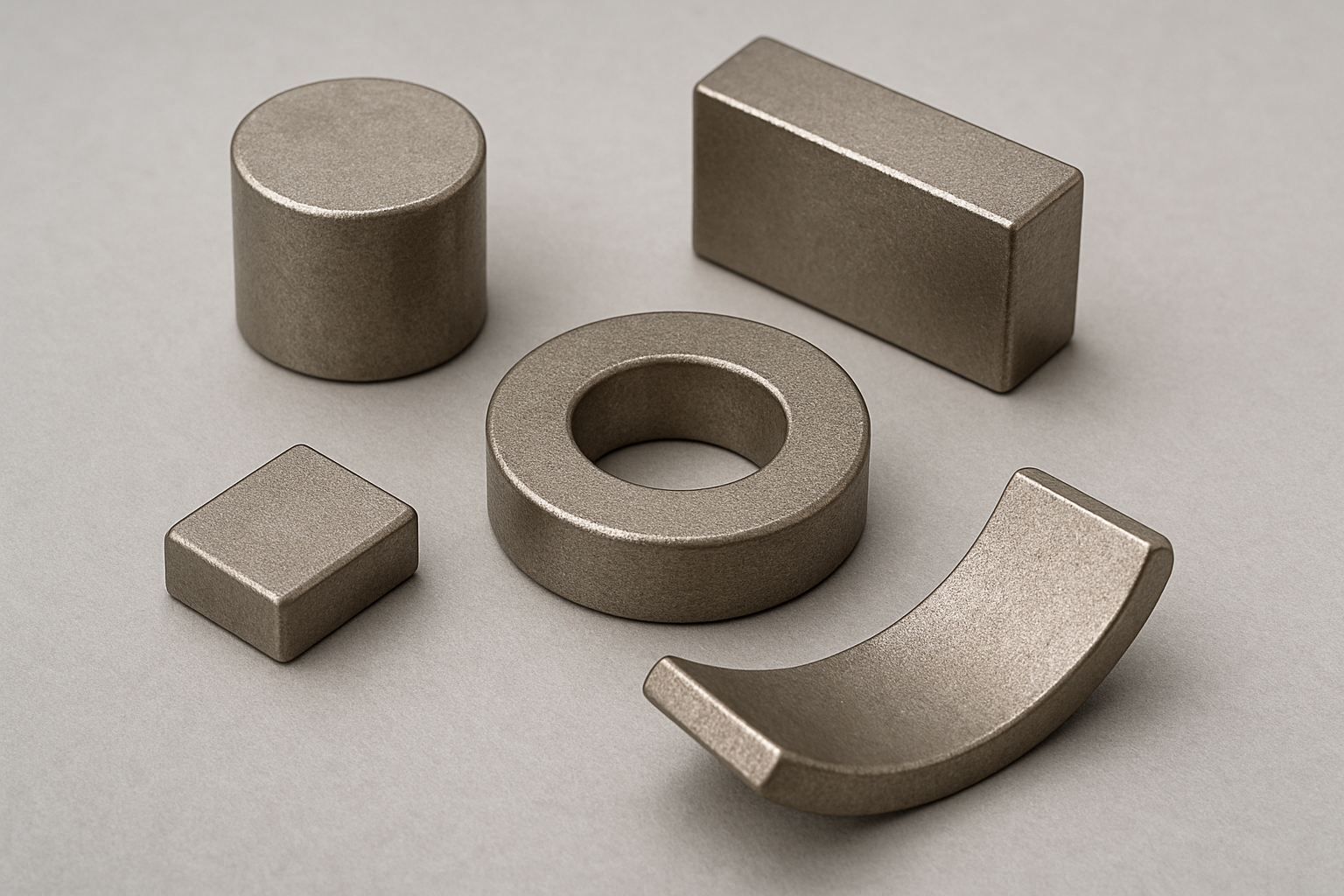

When choosing between Samarium Cobalt (SmCo) magnets and Neodymium (NdFeB) magnets, consider the following factors with specific figures and data:

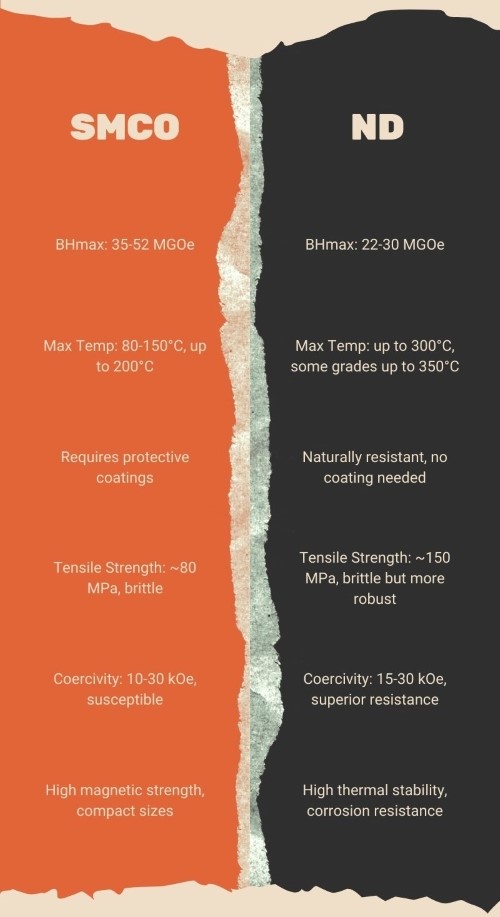

1. Magnetic Strength

- Neodymium Magnets: Known for their extremely high magnetic strength, with a maximum energy product (BHmax) ranging from 35 to 52 MGOe (Mega Gauss Oersteds).

- SmCo Magnets: Have a lower magnetic strength compared to Neodymium, with a BHmax typically between 22 to 30 MGOe.

Related reading: How to Choose a Permanent Magnet?

2. Temperature Stability

- Neodymium Magnets: Generally have a maximum operating temperature of 80°C to 150°C. High-temperature grades can reach up to approximately 200°C.

- SmCo Magnets: Exhibit excellent thermal stability, with operating temperatures up to 300°C or higher. Some grades can function at temperatures as high as 350°C.

3. Corrosion Resistance

- Neodymium Magnets: Susceptible to oxidation and corrosion. They typically require protective coatings such as nickel, zinc, or epoxy to prevent degradation.

- SmCo Magnets: Naturally more resistant to oxidation and corrosion, making them suitable for harsh environments without needing additional coatings.

4. Mechanical Properties

- Neodymium Magnets: Brittle and can crack or shatter under mechanical stress or impact. They have a tensile strength of about 80 MPa.

- SmCo Magnets: Also brittle but tend to be slightly more robust than Neodymium. They have a tensile strength of around 150 MPa.

5. Demagnetization Resistance

- Neodymium Magnets: Susceptible to demagnetization at high temperatures or if exposed to reverse magnetic fields, with a coercivity (Hcj) of 10 to 30 kOe.

- SmCo Magnets: Superior resistance to demagnetization, with a coercivity (Hcj) of 15 to 30 kOe, maintaining their magnetic properties under challenging conditions.

6. Application Suitability

- Neodymium Magnets: Ideal for applications requiring high magnetic strength in compact sizes, such as electric motors, hard drives, and consumer electronics.

- SmCo Magnets: Preferred in applications requiring high thermal stability, corrosion resistance, and reliable performance in harsh environments, such as aerospace, military, and high-temperature industrial uses.

Summary

The basic differences between SmCo and NdFeB magnets are in their performance. SmCo magnets operate better at higher temperatures, up to 350°C, and in more corrosive environments. In contrast, NdFeB magnets have a much stronger magnetic field, with the highest BHmax of 35-52 MGOe.

Considering these factors will help you select the appropriate magnet type for your specific application needs. For more information, please check Stanford Magnets.