Ten Types of Pot Magnets

What Are Pot Magnets?

Pot magnets, also known as cup or mounting magnets, are magnetic assemblies where a magnet is encased within a steel shell. This design amplifies the magnet's holding force on one side while shielding the other, making them invaluable in various industrial and commercial applications.

Pot magnets are widely used across industries. Common applications include:

- Industrial assembly: Holding, clamping, or positioning components

- Retail displays: Mounting signs, fixtures, and shelving

- Marine environments: Securing tools or equipment with corrosion-resistant versions

- Home and office: Magnetic hooks, mounts, or holders

- Search and retrieval: Fishing magnets to lift metal from water or hard-to-reach areas

- Electronics and sensors: Magnetic bases for devices and measuring instruments

Further reading: What Are the Types of Pot Magnets?

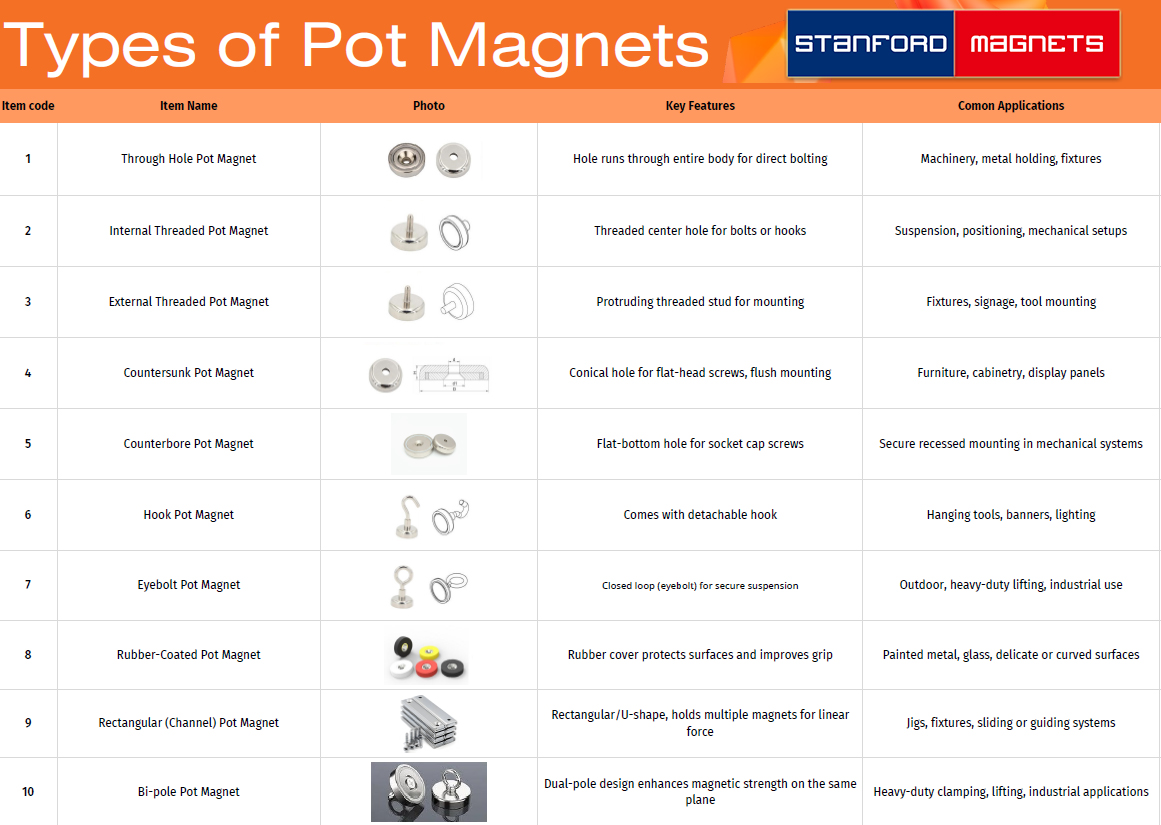

10 Types of Pot Magnets

Pot magnets are available in various structural designs, each suited for specific mounting and functional needs. Here are ten common types:

- Through Hole Pot Magnet

These magnets have a central hole that runs through the entire body, allowing them to be bolted directly to surfaces. They are widely used in machinery setups and for securely holding metal objects. - Internal Threaded Pot Magnet

Featuring a threaded hole at the center, these magnets can accommodate bolts, hooks, or other threaded fittings. They are ideal for suspension, positioning, or mechanical integration. - External Threaded Pot Magnet (Stud Type)

This type comes with an externally threaded stud protruding from the center. It's useful for quickly mounting or attaching the magnet to other structures, such as fixtures or signs. - Countersunk Pot Magnet

Designed with a conical countersunk hole, this magnet can be fixed flush to a surface using flat-head screws. It’s often used in cabinetry, furniture, or mounting displays. - Counterbore Pot Magnet

These magnets have a flat-bottomed bore hole (rather than a conical one), allowing for the use of socket head cap screws. They’re ideal for secure, recessed mounting in mechanical systems. - Hook Pot Magnet

Equipped with a detachable hook, this type is perfect for hanging tools, lights, banners, or other objects. It’s commonly used in retail, warehouses, and workshops. - Eyebolt Pot Magnet

Instead of a hook, these magnets come with a closed-loop eyebolt, providing a stronger and more secure hanging point. They are well-suited for outdoor and industrial lifting or suspension tasks. - Rubber-Coated Pot Magnet

These magnets are coated in rubber to prevent scratching surfaces and to improve grip. They’re ideal for delicate surfaces such as painted metal, glass, or automotive parts. - Rectangular (Channel) Pot Magnet

Shaped as a rectangle or U-channel, this type typically houses multiple magnets and provides strong linear holding force. It’s commonly used in jigs, fixtures, or sliding mechanisms. - Bi-pole Pot Magnet

These magnets feature a dual-pole configuration with north and south poles exposed on the same plane. This enhances the magnetic field and is ideal for heavy-duty applications that require strong holding force.

Summary Table

Other Types of Pot Magnets

Beyond standard types, several specialized pot magnets cater to specific needs:

- Rubber-Coated Pot Magnets: Encased in rubber to prevent surface damage and enhance grip, ideal for delicate surfaces.

- Fishing Magnets: Designed for retrieving metal objects from water bodies, these magnets are typically larger and encased to withstand underwater conditions.

- Channel Magnets: Consist of a magnet embedded in a steel channel, providing a strong magnetic field on one face, commonly used for mounting and holding applications.

Conclusion

Pot magnets are versatile tools with a range of types tailored to specific applications. To choose the appropriate pot magnet, you need to consider magnetic strength, temperature resistance, corrosion resistance, and mounting requirements.