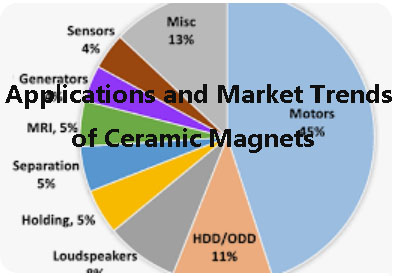

Top Applications of Ceramic Magnets: Uses and Market Trend

Ceramic magnets or ferrite magnets are a favorite of the new industrial revolution at all times with their robustness, economical price tag, and all-round magnetic nature. Comprising barium ferrite (BaFe₁₂O₁₉) or strontium ferrite (SrFe₁₂O₁₉) in overwhelming proportions, ceramic magnets are most cherished for their coercivity, corrosion resistance, and intermediate level of magnetism strength, which can be utilized for multiple applications. As compared to neodymium magnets, which are far better in magnetic performance but at far greater cost and lower thermal resistance, ceramic magnets discover a middle ground that has resulted in their widespread usage in industrial as well as household applications.

1. Electric Motors and Generators

The biggest application of ceramic magnets is in electric motors and generators from household appliances to industrial machinery. In electric motors, the magnets are employed to shape the electrical energy into mechanical movement, and in generators, vice versa, with the magnets converting mechanical energy into electrical energy. Ferrite magnets are applied very widely in AC and DC motors like industrial automation stepper motors, fans, pumps, and even alternative energy power generators like small windmills.

What renders ceramic magnets particularly well-suited for motors is that they possess a high coercivity in magnetism, typically within the range of 3000 to 4000 Oersted (Oe). This indicates the magnets are resistant to magnetic field loss when exposed to mechanical vibration and low heating. Furthermore, strontium ferrite magnets can be used continuously up to 250°C, which encompasses almost the entire motor application range. 2024 market data indicates that over 55% of small electric motors globally utilize ferrite magnets due to the balance of cost reduction and strength. In terms of cost, ferrite magnets are as inexpensive as 10–15% of neodymium per unit volume, which makes them cost-effective in volume production of motors.

Related reading: Why Choose Permanent Magnet Generators over Traditional Alternators?

2. Industrial Magnetic Separation

Besides motors, ceramic magnets also find application in magnetic separation technology for use in industries aimed at contaminant removal. Ferrite type magnetic separators are utilized by food processing facilities for the recovery of metal particles in flour, sugar, and grain. Recyclables plants utilize them for recovery of metallic contaminants from plastics, paper, etc., and mining plants use them for iron ore benification.

Their behavior in such uses is based on their surface flux density, typically in the range of 0.35 to 0.45 Tesla, as high as to be able to retain ferrous particles without influencing the mass material. Ferrite magnets are also extremely chemically and mechanically resistant and can be able to withstand abrasion materials along with mild acidic environments without undergoing notable degradation. Market forecasts indicate ferrite magnets magnetic separation machinery demand will increase 3–5% a year for the next five years, reflecting the movement toward industrial automation and better standards of contamination control.

3. Magnetic Assemblies and Holding Applications

Apart from industrial applications, ceramic magnets also appear ubiquitous in hold, fasten, and clamp applications. They appear in cabinet door catches, magnetic hooks, clamps used in metalwork, and magnetic assembly line fixtures. The reason why ferrite magnets are so popular in such applications is due to the fact that they are stable long-term magnetization and resistant to corrosion, something indoor usage would otherwise ruin less permanent magnets.

Their ability to be formed also makes them flexible. Ceramic magnets can be molded or sintered as discs, blocks, and rings so that engineers can order the product to exacting specifications. The remanence of off-the-shelf ferrite magnets at around 0.25 to 0.45 Tesla is sufficient to deliver good holding force without the added expense of higher efficiency magnets.

4. Sensors and Actuators

Ceramic magnets also have uses in sensors and actuators where accurate, noncontact motion detection is required. Proximity sensors, reed switches, Hall-effect sensors, and small actuators all employ ferrite magnets to provide a consistent magnetic field. With high coercivity, they can withstand demagnetization by error even in electromagnetic interference conditions, and temperature stability up to 250°C ensures flawless operation in automotive and industrial applications. Moreover, the capability of ferrite magnets to be shaped into precise, narrow forms offers a venue for application within small electronic packaging, making them an opposite of modern automation systems.

5. Applications of Audio and Electronics

Ferrite magnets are also the standard for the audio and electronics industry, particularly for microphones, speakers, and headphones. Where neodymium magnets offer more field strength for high-fidelity devices, ferrite magnets remain the champions in mid-range usage through cost savings and damage resistance. A common ferrite magnet in a speaker will generate a surface flux density of around 0.3–0.4 Tesla, sufficient to yield clean mid-range frequencies. More than 60% of the world mid-market segment speakers use ferrite magnets, as per the industry, representing their use in mass-market electronics.

Further reading: Key Applications of Magnets in Audio Devices

6. Education, DIY, and Craft Uses

In both school and home environments, ceramic magnets are used extensively in STEM experiments, DIY projects, and crafts. Their low toxicity, combined with relatively low cost and consistent magnetic properties, make them ideal for safe classroom demonstration of electromagnetic induction, levitation, and magnetic fields. They also have applications as refrigerator magnets and magnetic building sets, where consistency and capacity to be formed into exactly the form required are valuable. Ferrite magnets will not cause any harm if crushed, unlike the neodymium magnets, which is a serious issue in the product being sold to children and students.

7. Therapeutic and Health Devices

Ceramic magnets have been employed in magnetic therapy devices, including bracelets, insoles, and wearable items with the hope of improving circulation or pain alleviation. Although they are unproven clinically effective, ferrite magnets are perfect for such applications because their magnetization is not affected for years of usage and their corrosion resistance ensures longevity even when exposed to the typical day-long battery of perspiration and dampness.

8. Magnetic Lifting and Retrieval Tools

Lastly, ceramic magnets find common application in magnetic pick-up, lifting, and organizational aids. Ferrite magnets are employed by pickup tools, tool holders, and magnetic sweepers to lift or suspend small to mid-sized ferromagnetic pieces. These magnets feature an average surface field of 0.35–0.4 Tesla and provide sufficient strength for workshop applications and industrial application and offer resistance to demagnetization on repeat switching.

Conclusion

Ceramic magnets find usage as widespread as in industrial motors and magnetic separators to consumer goods, educational sets, and therapy devices. Their coercivity, thermal stability, corrosion resistance, and economical cost guarantee enduring supremacy for industrial as well as consumer markets.

Since the global ferrite magnet market is also projected to be more than $8 billion by 2030, it is critical that product design engineers, manufacturers, and designers gain knowledge regarding different applications and performance requirements of ceramic magnets in a bid to attain best cost as well as performance.