A Detailed Guide on the Samarium Cobalt Magnet

Samarium cobalt (SmCo), is a member of the lanthanide group on the periodic table. It is a close relative of neodymium. Both of them are called rare-earth elements. They are used to manufacture powerful and permanent magnets. There is a lot of information that a prospective customer should know before buying samarium cobalt magnets. A simple guide is presented below:

Samarium Cobalt Magnet

What are SmCo Magnets?

Samarium cobalt magnets are composed of two primary phases:

-

SmCo5: This phase has a lower magnetic energy product but excellent temperature stability.

-

Sm2Co17: This phase offers higher magnetic strength and improved temperature resistance.

The combination of these phases allows SmCo magnets to deliver a balance of high magnetic performance and reliability in extreme environments.

Samarium cobalt magnets are known for the following key properties:

-

High Magnetic Strength:SmCo magnets have a magnetic energy product (BHmax) ranging from 16 to 32 MGOe, making them the second strongest type of rare earth magnet after neodymium magnets.

-

Excellent Temperature Stability:These magnets can operate at temperatures up to 300°C or higher, making them ideal for high-temperature applications.

-

Corrosion Resistance:Unlike neodymium magnets, SmCo magnets are naturally resistant to corrosion and do not require protective coatings.

-

High Coercivity:SmCo magnets have very high coercivity, meaning they are highly resistant to demagnetization.

-

Brittleness:SmCo magnets are more brittle than neodymium magnets and can chip or crack if mishandled.

-

Higher Cost:Due to the inclusion of cobalt, SmCo magnets are more expensive than neodymium magnets.

How are samarium cobalt magnets made?

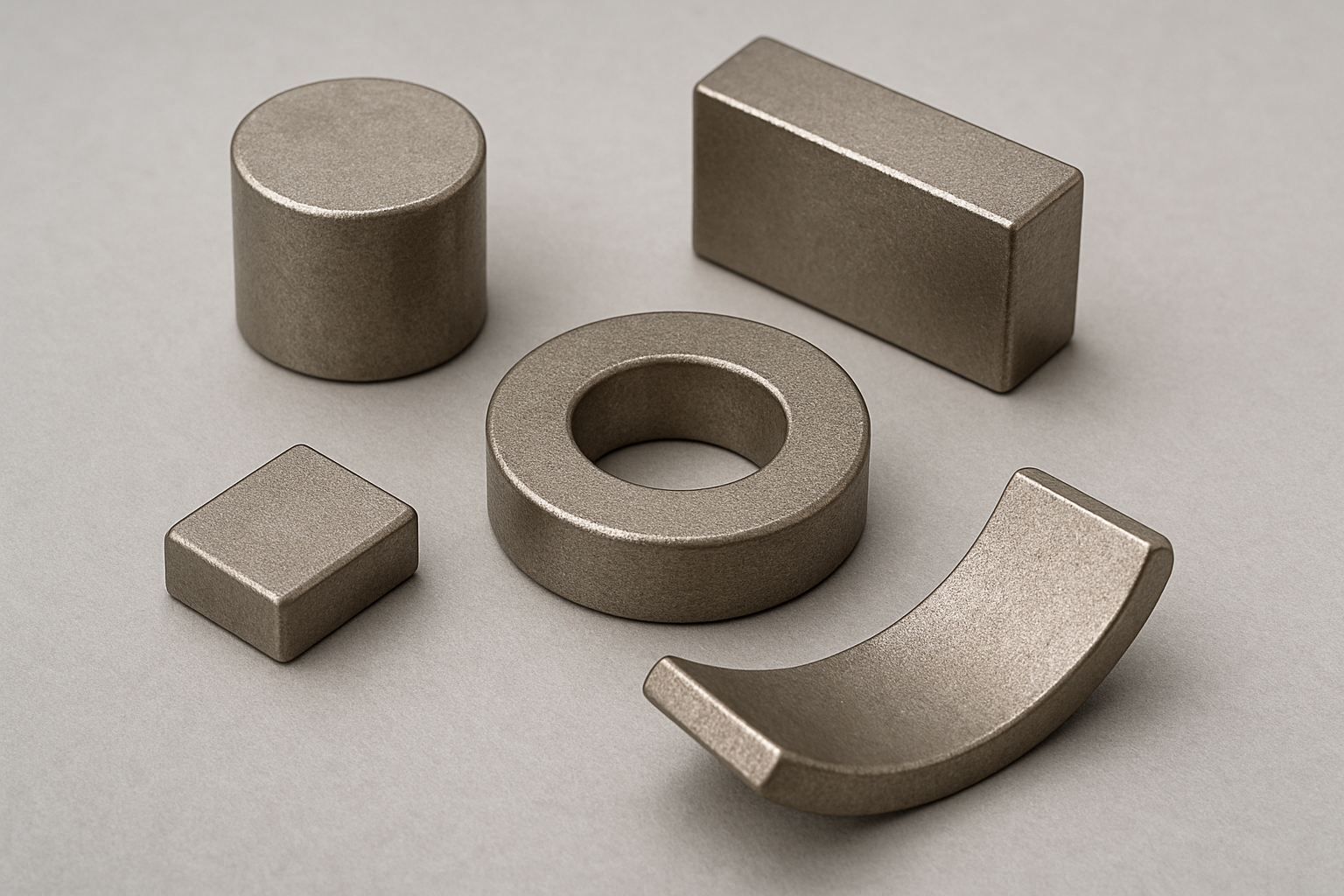

There are two methods for manufacturing these products. One method is called sintering. Super-fine samarium powder is molded into a solid thing through pressing. The first technique is called isostatic pressing. It entails a unique rubber die that hosts SmCo powder as it is gently pressed with equal force in all directions. The isostatic method produces a solid material with higher magnetic properties but tinier in size. There is also an observation that isostatically produced parts have magnetic characteristics that boast lower uniformity.

Compression bonding is another technique used to make SmCo magnets. During this process, a very special type of samarium powder is mixed with a plastic carrier substance. Then it is die-pressed and heated. The compression-bonded components often have close tolerance thus demanding no machine finishing. What's more, these parts can be transformed into more complicated magnet shapes. Compared to sintered magnets, compression-bonded units have lower-energy products.

.

sintered samarium cobalt magnet

SmCo Magnets: Manufacturing and Polishing Processes

--Samarium cobalt: machining

As briefly mentioned above, SmCo is as brittle as the neodymium rare-earth magnet. It could cut and crack easily. Hence, users are not advised to use crude tools to machine samarium cobalt magnets. Special diamond tools should be used for grinding instead. Likewise, grinding work must be done with generous amounts of coolant to reduce the damage that could arise due to heat, such as fires (for flammable dust caused by grinding) or cracks. It's wise to let professional machinists do the grinding work.

--Magnetizing

Just like neodymium magnets, SmCo magnets require very strong and high magnetic fields to reach saturation. Magnetization must, therefore, be done after assembling. To make assemblies special, adhesives that fasten brittle SmCo magnets are utilized.

--Handling tips

Although a samarium cobalt magnet boasts a very strong magnetic field, it may crack or chip easily. The same case applies to neodymium rare-earth magnets. They are brittle and must all be handled with a lot of care. Proper handling can prevent personal injuries and hazards. These magnets should never be allowed to accelerate at a high speed to an attracting object. They could collide and shatter into particles. Kids should not handle SmCo magnets or any other rare-earth magnets as these can be very dangerous if swallowed or allowed to pinch the skin.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the samarium cobalt magnet. If you want to know more about samarium cobalt magnets or other magnet products, we advise you to visit Stanford Magnets for more information.