An Introduction to Vibrating Sample Magnetometer

A vibrating sample magnetometer is an instrument that is used to measure magnetic properties. It is also called a Foner magnetometer. This instrument works based on Faraday's Law of Induction which states that induced voltage in a circuit is directly proportional to the changing magnetic field in the circuit. In 1955, Simon Foner, a scientist at MIT Lincoln Laboratory invented the first vibrating sample magnetometer.

Components of a Vibrating Sample Magnetometer

A vibrating sample magnetometer typically has the following components:

Cooled Electromagnet/ Power Supply

The actively cooled electromagnet provides the constant magnetic field that is needed to magnetize the sample to be tested.

The Amplifier

As its name implies, the amplifier amplifies the signals that the pick-up coils create.

Sensor Coils

They are also called the pick-up coils. It is in these sensor coils that the sample induces an electric current. This electric current is the signal that the amplifier gets to amplify.

Vibration Exciter and Sample Holder

The vibration exciter and the sample holder rod are attached. The vibration exciter causes the sample to vibrate at about 85 Hz. The sample rod on the other hand can rotate the sample to the desired orientation.

Control Chassis

The control chassis regulates the oscillation of the exciter at 85 Hz.

Meter

This is used to measure magnetic strength.

Computer Interface

The computer interface contains software that can be used to measure data. The computer interface can also record the data measured.

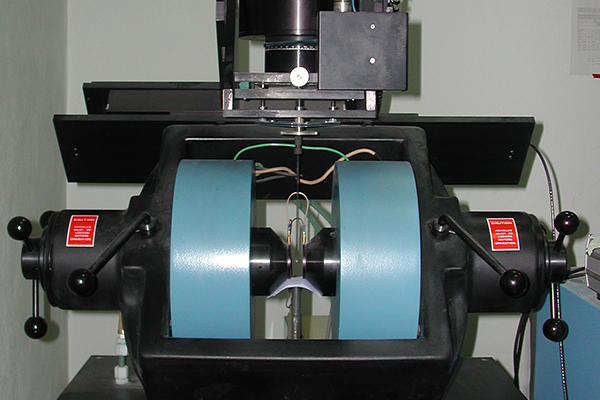

Vibrating Sample Magnetometer. Image Source: commons.wikimedia.org

How a Vibrating Sample Magnetometer Functions

To use a vibrating sample magnetometer, the sample to be tested is first placed in a constant magnetic field. The constant magnetic field will magnetize the sample if the sample is magnetic. The magnetic field will organize the magnetic domains in the sample to achieve this. The magnitude of magnetization is directly related to the strength of the magnetic field. Pick-up coils detect changes in the magnetic stray field as the sample vibrates. The magnetic stray field is a magnetic field formed around the sample thanks to the magnetic dipole moment of the sample. The fluctuations of the magnetic stray field will induce an electric current in the pick-up coils following Faraday's Law. Amplifiers will amplify the electric current that the fluctuating magnetic field causes. These amplifiers are then connected to a computer system. The computer system contains software that can interpret the sample's level of magnetization as well as how much of an influence the strength of the constant magnetic field had on the sample's magnetization.

Magnetic Properties of Materials

As stated above vibrating sample magnetometers are used to measure the magnetic properties of materials. What are these magnetic properties? Take a look at them.

Magnetic Susceptibility

Magnetic susceptibility is a measure of how much a material can be magnetized in the presence of a magnetic field. The level of magnetization is usually directly proportional to the magnitude of the magnetic field. It is usually represented as Xm.

Intensity of Magnetisation

Magnets change their moment when they are placed in an external magnetic field. The intensity of magnetization is a measure of the change in the magnetic moment for each unit volume. It is represented as I.

Magnetic Intensity

This is also called the magnetic field strength. It is the extrinsic magnetic field in a material created by an external electric current. It is represented as H.

Magnetic Retentivity

This is the ability of a material to maintain its magnetism after the magnetizing force is removed.

Magnetic Coercivity

It is the measure of a magnet's ability to resist an external magnetic field without losing its magnetization.

Precautions for Operating a Vibrating Sample Magnetometer

When operating a vibrating sample magnetometer, some precautions need to be taken to prevent accidents.

- Ensure that the power requirement of the vibrating sample magnetometer is in tune with the alternating current power at your location before you install the system.

- Do not eat or drink while using the vibrating sample magnetometer to avoid spills.

- Ensure that the vibrating sample magnetometer is well grounded to avoid electrical shock.

- Ensure that the vibrating sample magnetometer is well ventilated and stored in a cool dry place.

- Do not operate the vibrating sample magnetometer if you have a metallic implant or are wearing a pacemaker.

- All ferromagnetic objects should be kept at least 16 ft away from the vibrating sample magnetometer.

Advantages of Vibrating Sample Magnetometers

- They have a high level of precision and accuracy

- Materials can be tested at different orientations with a vibrating sample magnetometer

Disadvantages of Vibrating Sample Magnetometers

- Their efficiency is affected by temperature.

- Fragile materials can not be tested with a vibrating sample magnetometer.

Conclusion

Vibrating Sample Magnetometers are a welcome technology that makes it easy to get accurate measurements of magnetic properties using Faraday's Law of Induction. Thank you for reading our article and we hope it can help you to have a better understanding of magnet coating.

If you want to learn more about magnets, we would like to advise you to visit Stanford Magnets for more information. As a leading magnet supplier across the world, Stanford Magnets has been involved in the R&D, manufacturing, and sales of magnets since the 1990s. It provides customers with high-quality permanent magnets like SmCo magnets, neodymium magnets, AlNiCo magnets, and ferrite magnets (ceramic magnets) at a very competitive price.