Ceramic Magnets Grade Datasheet

Introduction

Ceramic magnets, also known as ferrite magnets, are a class of permanent magnets made from iron oxide (Fe₂O₃) combined with either barium or strontium carbonate. Ceramic magnets have been an essential component in various industries for decades, owing to their robust magnetic properties and low production cost.

Let’s learn about the different ceramic magnet grades, their unique properties, and common applications with detailed comparison table and datasheet.

What Are Ceramic Magnets?

Ceramic magnets are permanent magnets made from a mixture of iron oxide and either strontium carbonate (SrCO₃) or barium carbonate (BaCO₃). These materials are sintered in a high-temperature furnace, forming the crystalline structure that gives the magnets their permanent magnetic properties.

Ferrite magnets are widely available in different grades, each optimized for specific applications. The grades are determined based on factors such as coercivity (resistance to demagnetization), energy product (magnetic strength), and temperature resistance.

Ceramic Magnets Grade Datasheet

Ceramic Magnet Grades

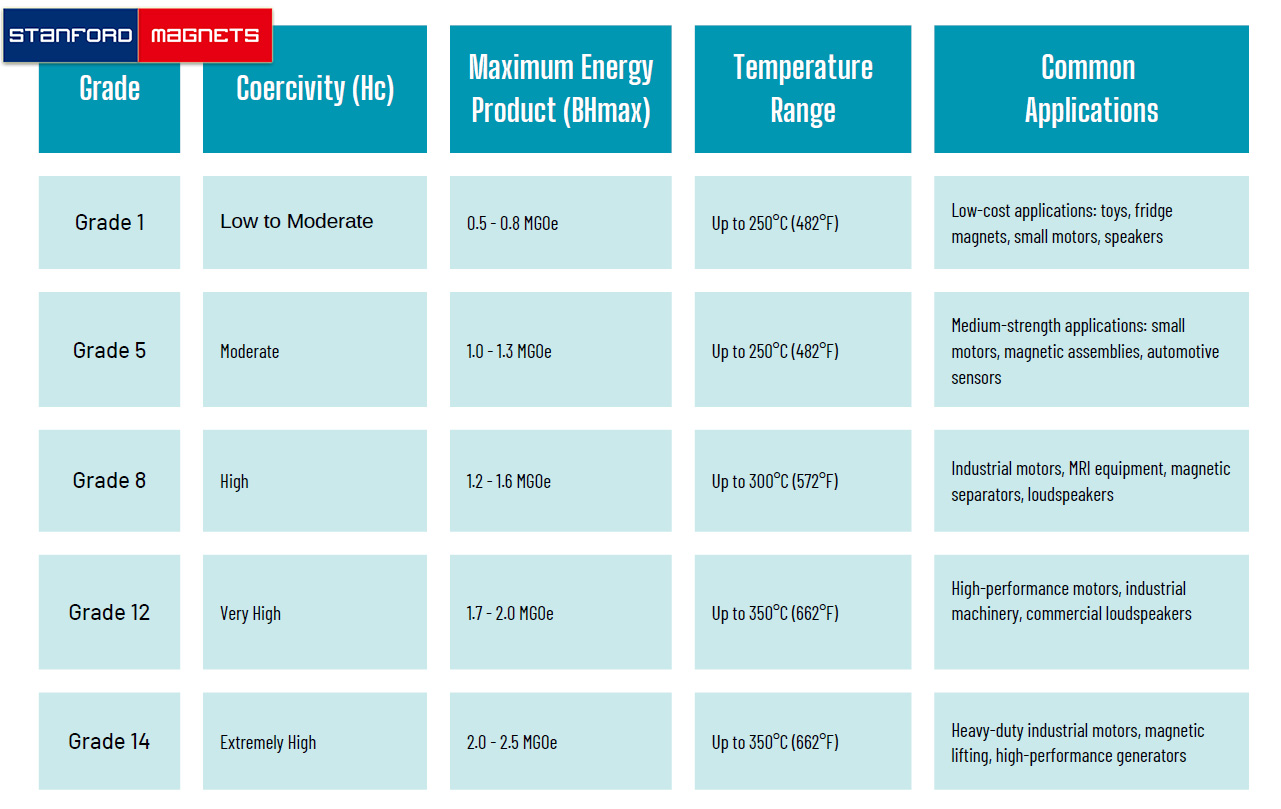

The grades of ceramic magnets typically range from Grade 1 to Grade 14, with each grade offering specific characteristics. The magnetic properties, such as coercivity and maximum energy product, increase with the grade.

Grade 1 (Standard Ferrite Magnets)

Grade 1 ceramic magnets are the most basic type of ferrite magnets. They are made using barium ferrite (BaFe₁₂O₁₉) and offer relatively low magnetic strength compared to higher grades. These magnets are ideal for applications that do not require a strong magnetic field. They are also highly cost-effective, making them a popular choice in low-energy applications.

- Coercivity: Low to moderate

- Energy Product (BHmax): 0.5 - 0.8 MGOe

- Temperature Range: Up to 250°C (482°F)

Applications: Grade 1 magnets are commonly used in low-cost applications such as toys, fridge magnets, and small motors. They are also used in small speakers and educational devices, where the magnetic field strength is not a critical factor.

Grade 5 (High-Energy Ferrite Magnets)

Grade 5 ceramic magnets are made from barium ferrite (BaFe₁₂O₁₉) and have improved magnetic strength compared to Grade 1 magnets. These magnets offer a moderate magnetic field strength and are still relatively cost-effective.

- Coercivity: Moderate

- Energy Product (BHmax): 1.0 - 1.3 MGOe

- Temperature Range: Up to 250°C (482°F)

Applications: Grade 5 ferrite magnets are commonly used in applications that require a moderate magnetic strength, such as small motors, magnetic assemblies, and automotive sensors. They are also used in some loudspeakers and other consumer electronics where a higher magnetic field is needed but high cost is not justified.

Grade 8 (High-Performance Ferrite Magnets)

Grade 8 ceramic magnets, made from strontium ferrite (SrFe₁₂O₁₉), offer a significant improvement in magnetic strength and temperature resistance over Grade 5 magnets. They have a higher energy product and can maintain their magnetic properties in more demanding environments.

- Coercivity: High

- Energy Product (BHmax): 1.2 - 1.6 MGOe

- Temperature Range: Up to 300°C (572°F)

Applications: Grade 8 magnets are commonly used in motors, magnetic resonance imaging (MRI) equipment, and magnetic separators. Their higher strength makes them ideal for industrial applications where a stronger magnetic field is required, yet cost considerations are still important.

Grade 12 (Super High-Performance Ferrite Magnets)

Grade 12 ceramic magnets are known for their high magnetic strength and excellent performance at higher temperatures. Made from strontium ferrite (SrFe₁₂O₁₉), they are designed for high-energy applications where the magnet is exposed to challenging environmental conditions.

- Coercivity: Very high

- Energy Product (BHmax): 1.7 - 2.0 MGOe

- Temperature Range: Up to 350°C (662°F)

Applications: Grade 12 ferrite magnets are used in high-performance motors, industrial machinery, and high-power magnetic applications. Their ability to withstand elevated temperatures makes them suitable for environments where other magnets might fail. They are also used in large loudspeakers and heavy-duty machinery.

Grade 14 (Ultra High-Performance Ferrite Magnets)

Grade 14 ceramic magnets are the highest-performing ferrite magnets available. These magnets are made from strontium ferrite (SrFe₁₂O₁₉) and offer the best combination of high magnetic strength and temperature resistance. Their high coercivity and energy product make them suitable for demanding applications where high magnetic strength and stability are required.

- Coercivity: Extremely high

- Energy Product (BHmax): 2.0 - 2.5 MGOe

- Temperature Range: Up to 350°C (662°F)

Applications: Grade 14 magnets are used in heavy-duty industrial motors, magnetic lifting devices, and high-performance generators. Their superior magnetic strength and temperature resistance make them ideal for applications in harsh environments.

Conclusion

Ceramic magnets are a reliable, cost-effective solution for a wide range of applications. The different grades of ceramic magnets, ranging from Grade 1 to Grade 14, provide varying magnetic strengths, temperature stability, and cost levels. Whether you're designing consumer electronics or heavy-duty industrial equipment, understanding the unique properties of these magnets can help you select the ideal grade for your project. For more information about ceramic magnets grade, please check Stanford Magnets.