Coatings & Adhesives of Ferrite Magnets

Ferrite magnet is the most common magnet in our lives. It is a permanent magnet mainly made of SrO or BaO and Fe2O3 as raw materials. Compared with other permanent magnets, ferrite magnets are hard and brittle and have lower magnetic energy. However, ferrite magnets also have their unique advantages. They are not easily demagnetized or corroded, and their production process is simple and they are usually low in price. As we all know, many magnets, such as neodymium magnets, generally need coatings for protection to achieve the purpose of anti-corrosion, so do ferrite magnets need coatings? The answer is YES. So in this article, let's take a look at the coatings & adhesives of ferrite magnets.

Coatings & Adhesives of Ferrite Magnets

Coatings & Adhesives of Ferrite Magnets

Coatings for Ferrite Magnets

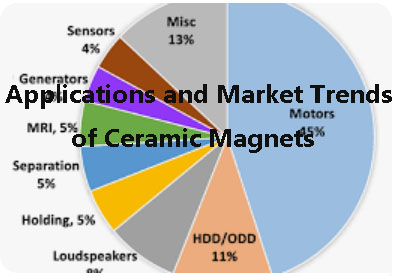

Ferrite magnets, also called ceramic magnets, are made of iron oxide, and they will not corrode when immersed in water (or even saltwater) or exposed to moisture. They are even resistant against solvents, weak acids, lubricants, salts, and gases. This is just one of the features that make ferrite magnets very popular in many applications.

Due to the corrosion resistance of ferrite magnets, they can usually be used without any additional coating and has a long service life, which usually exceeds the lifecycle of the application they are used in. Of course, for professional applications such as medical instruments, ferrite magnets can be coated to ensure that any dust in the magnet is locked in it. Ferrite magnets can also be coated with a coating to disguise their dark gray. Typical coatings of ferrite magnets include rubber and polytetrafluoroethylene (PTFE, also known as Teflon Ni-Cu-Ni plus Epoxy).

Adhesives

With the right adhesive, both magnetic and non-magnetic materials can be stuck to other surfaces. A clean and grease-free surface provides the best bonding surface. At Stanford Magnets, we recommend the following adhesives for use with our magnets: Araldite Rapid Adhesive and Loctite Industrial Strength Adhesive.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the coatings & adhesives of ferrite magnets. If you want to know more about ferrite magnets or other types of magnets, we would like to advise you to visit Stanford Magnets for more information.

As a leading magnet supplier across the world, Stanford Magnets has been involved in R&D, manufacturing, and sales of magnets since the 1990s. It provides customers with high-quality permanent magnets like SmCo magnets, neodymium magnets, AlNiCo magnets, and ferrite magnets (ceramic magnets) at a very competitive price.