Soft Magnetic Materials vs Hard Magnetic Materials

Magnetic materials are essential to modern electrical and electronic systems. They serve critical roles in energy conversion, signal transmission, and mechanical motion. Broadly, these materials are divided into two categories: soft magnetic materials and hard magnetic materials. Let’s learn about these two types in this article.

[1]

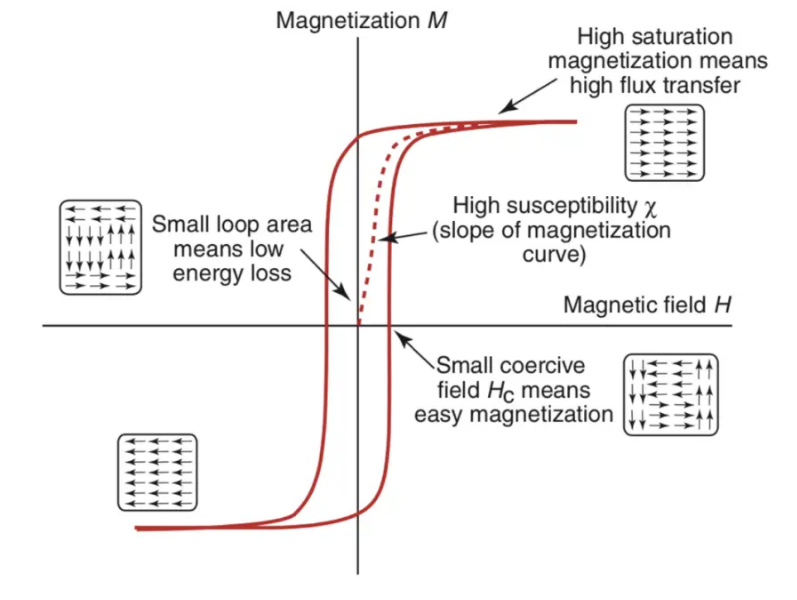

What Are Soft Magnetic Materials?

Soft magnetic materials are those that can be easily magnetized and demagnetized. They exhibit low coercivity and high permeability, allowing them to support the rapid and reversible changes in magnetization required in alternating current (AC) systems. Their low hysteresis and eddy current losses make them particularly well-suited for dynamic electromagnetic environments.

These materials are typically used in components where the magnetic field needs to vary quickly and efficiently—such as cores in transformers, inductors, and electric motor stators. A key advantage of soft magnetic materials is their ability to carry magnetic flux with minimal energy loss, which is critical for improving efficiency in power systems.

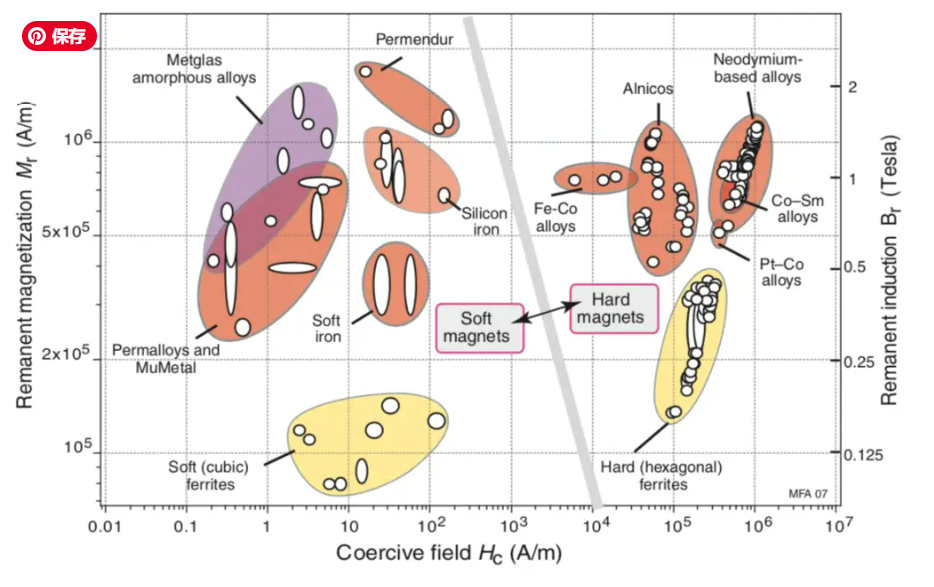

Typical Examples of Soft Magnetic Materials

Several classes of materials are engineered to serve as soft magnetic components:

- Silicon Steels

Silicon is added to pure iron to reduce eddy current losses and improve resistivity. These are commonly used in transformers and electrical machines due to their favorable magnetic properties and ease of processing. - Soft Ferrites

Ferrites are ceramic compounds composed of iron oxide combined with other metal oxides. They are known for high electrical resistivity and are widely used in high-frequency transformers and inductors. - Amorphous and Nanocrystalline Alloys

These materials have a disordered atomic structure, offering extremely low coercivity and high saturation magnetization. They are ideal for high-efficiency transformers and compact magnetic devices. - Permalloy (Nickel-Iron Alloys)

With a typical composition of about 80% nickel and 20% iron, permalloy exhibits very high magnetic permeability and is often used in magnetic shielding and sensor applications.

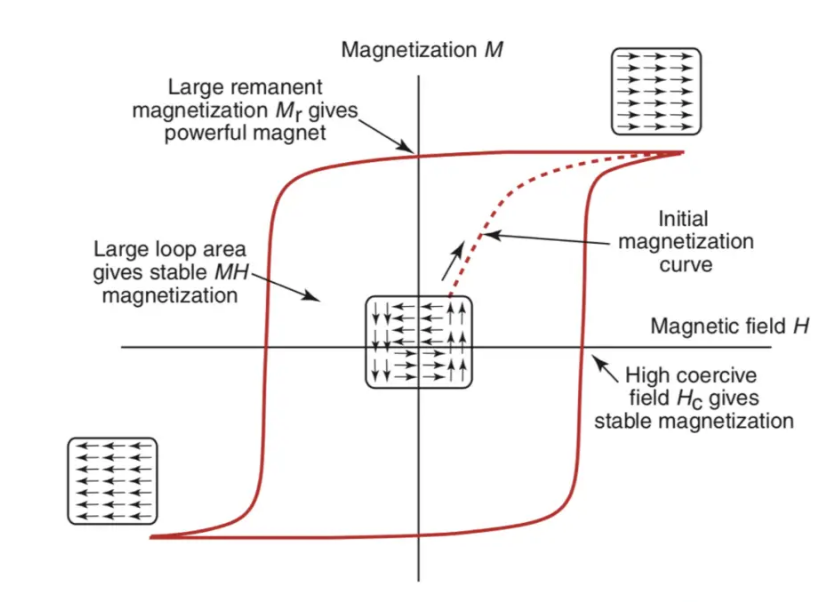

What Are Hard Magnetic Materials?

Hard magnetic materials, also referred to as permanent magnets, retain a significant amount of magnetization after an external magnetic field is removed. These materials exhibit high coercivity and high remanence, allowing them to maintain strong magnetic fields over time and under adverse conditions.

They are typically used in applications where a persistent magnetic field is required, such as in electric motors, generators, magnetic sensors, and consumer electronics. Hard magnets are also integral to renewable energy systems, such as wind turbines, where long-term magnetic stability is essential.

Common Types of Hard Magnetic Materials

- NdFeB (Neodymium-Iron-Boron)

These rare-earth magnets are among the strongest known, offering high energy products (up to 52 MGOe). They are widely used in compact, high-efficiency motors and renewable energy applications. - SmCo (Samarium-Cobalt)

Known for their excellent thermal stability and corrosion resistance, SmCo magnets are used in aerospace and other high-temperature environments. - AlNiCo (Aluminum-Nickel-Cobalt)

Although weaker than rare-earth magnets, AlNiCo alloys perform well at high temperatures and are used in sensors, pickups, and instrumentation. - Hard Ferrites (Ceramic Magnets)

Composed of iron oxide and barium or strontium carbonate, hard ferrites are inexpensive, corrosion-resistant, and widely used in speakers, motors, and magnetic assemblies.

Comparing Soft and Hard Magnetic Materials

|

Property |

Soft Magnetic Materials |

Hard Magnetic Materials |

|

Coercivity |

Low |

High |

|

Retentivity |

Low |

High |

|

Permeability |

High |

Low to moderate |

|

Hysteresis Loss |

Low |

High |

|

Energy Product (BHmax) |

Low |

High |

|

Reusability in Cyclic Fields |

Excellent |

Poor |

|

Magnetization Reversal |

Easy |

Difficult |

AC Applications

Alternating current (AC) applications demand materials that can undergo rapid magnetization and demagnetization with minimal energy loss. Soft magnetic materials such as silicon steels and ferrites are indispensable in:

- Power transformers

- AC motors

- Inductors

- Relays and solenoids

- Magnetic amplifiers

In these applications, low core losses—both hysteresis and eddy current—are essential for efficiency and thermal management.

DC Applications

Direct current (DC) applications often require permanent magnetic fields, making hard magnetic materials the preferred choice. Their stability and strength allow them to perform reliably over long operational lifespans. Common DC applications include:

- Permanent magnet motors

- DC generators

- Magnetic holding devices

- Sensors and encoders

- Magnetic separation equipment

In these settings, the high coercivity and remanence of hard magnetic materials ensure consistent performance without external excitation.

Conclusion

Both soft and hard magnetic materials are foundational to modern technology. Soft magnetic materials enable efficient energy transfer and control in variable magnetic fields, particularly in AC systems. Hard magnetic materials provide strong, stable magnetic fields in DC applications where long-term performance is essential. For more magnetic materials, please check Stanford Magnets.

Reference:

[1] C. U. O. T. (2023, April 13). Breakthrough in magnetic quantum material paves way for ultra-fast sustainable computers. Physics Organization. Retrieved April 22, 2025, from https://phys.org/news/2023-04-breakthrough-magnetic-quantum-material-paves.html