Everything You Need to Know About Rare Earth Magnets

Do you want to know about rare earth magnets, huh? Well, you've come to the right place! Stanford Magnets is the magnet expert, so if you have a question that's not answered below, email us and we'll answer it!

Rare Earth Magnets

Are rare earth magnets really rare?

Rare earth magnets are a type of permanent magnet made from alloys of rare earth elements. They are known for their exceptional magnetic strength, high energy density, and superior performance compared to other types of magnets. Despite their name, rare earth elements are not actually rare—they are relatively abundant in the Earth’s crust but are difficult to mine and refine, which makes them valuable.

These magnets are widely used in various industries due to their ability to generate strong magnetic fields in compact sizes. Their unique properties have revolutionized technology, enabling advancements in electronics, energy, healthcare, and more.

What Are the Difference between Neodymium Magnets and SmCo Magnets?

Rare earth magnets are the most powerful permanent magnets available, and they are primarily divided into two types: Neodymium Magnets (NdFeB) and Samarium-Cobalt Magnets (SmCo). Both are made from alloys of rare earth elements, but they differ in composition, properties, and applications. Below are their grades, strengths, and key differences.

1. Neodymium Magnets (NdFeB): Properties and Grades

Neodymium magnets are made from an alloy of neodymium, iron, and boron (NdFeB). They are the strongest type of permanent magnets commercially available, with a magnetic energy product (BHmax) ranging from 35 to 52 MGOe.

- Extremely High Magnetic Strength: Neodymium magnets generate the strongest magnetic fields of any permanent magnet, making them ideal for applications requiring high performance in compact sizes.

- Compact and Lightweight: Their high energy density allows for smaller and lighter designs, which is particularly beneficial in industries like electric vehicles and consumer electronics.

- Prone to Corrosion: Neodymium magnets are susceptible to corrosion and often require protective coatings such as nickel, zinc, or epoxy.

- Temperature Sensitivity: Standard grades can lose their magnetic properties at temperatures above 80°C to 200°C, depending on the grade. However, high-temperature grades with added dysprosium (Dy) or terbium (Tb) can operate at elevated temperatures.

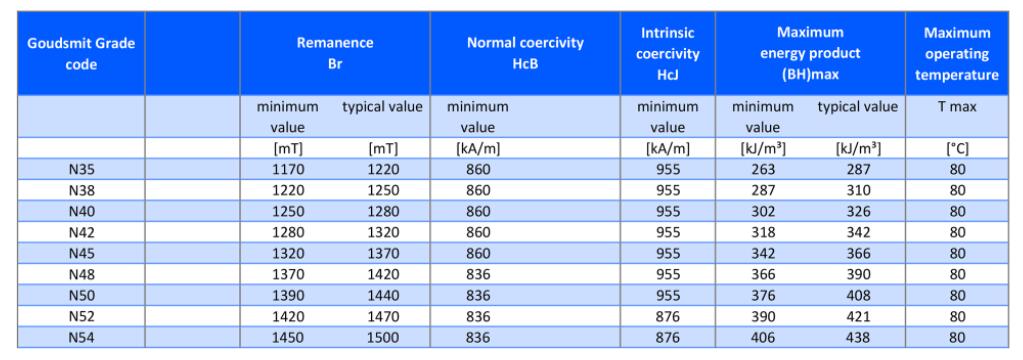

Neodymium magnets are classified by grades, which indicate their maximum energy product and temperature resistance. Common grades include:

- N35 to N52: Standard grades with varying magnetic strengths.

- N30H to N55H: High-temperature grades (up to 120°C).

- N30SH to N50SH: Super high-temperature grades (up to 150°C).

- N30UH to N48UH: Ultra-high-temperature grades (up to 180°C).

- N30EH to N45EH: Extreme high-temperature grades (up to 200°C).

Neodymium magnets are widely used in electric vehicles (EVs), wind turbines, hard drives, headphones, industrial motors, and consumer electronics due to their unmatched strength and compact design.

2. Samarium-Cobalt Magnets (SmCo): Properties and Grades

Samarium-cobalt magnets are made from an alloy of samarium and cobalt (SmCo). They are the second strongest type of rare earth magnets, with a magnetic energy product (BHmax) ranging from 16 to 32 MGOe.

- High Magnetic Strength: While slightly weaker than neodymium magnets, SmCo magnets still offer exceptional magnetic performance.

- Excellent Temperature Stability: These magnets can operate at temperatures up to 300°C or higher, making them ideal for high-temperature environments.

- Corrosion-Resistant: Unlike neodymium magnets, SmCo magnets do not require protective coatings, as they are naturally resistant to corrosion.

- Higher Cost: The inclusion of cobalt makes SmCo magnets more expensive than neodymium magnets.

- Brittle: SmCo magnets are more brittle and prone to chipping or cracking compared to neodymium magnets.

Samarium-cobalt magnets are also classified by grades, which indicate their magnetic strength and temperature resistance. Common grades include:

- SmCo5: Lower magnetic strength but excellent temperature stability.

- Sm2Co17: Higher magnetic strength and improved temperature resistance.

Samarium-cobalt magnets are commonly used in aerospace, defense systems, high-temperature motors, medical devices, and satellite equipment due to their ability to perform reliably in extreme conditions.

How to Choose: Neodymium Magnets vs Samarium Cobalt Magnets

Neodymium magnets are the go-to choice for high-performance applications requiring maximum strength and compactness, while samarium-cobalt magnets excel in high-temperature and corrosive environments. Understanding their properties, grades, and limitations can help you choose the right magnet for your specific needs.

Below is a detailed comparison of their properties, supported by data. For more information, please check Stanford Magnets.

|

Property |

(NdFeB) |

Samarium-Cobalt Magnets (SmCo) |

|

Magnetic Strength |

35–52 MGOe |

16–32 MGOe |

|

Temperature Stability |

Up to 80°C–200°C (standard) |

Up to 300°C or higher |

|

Corrosion Resistance |

Prone to corrosion (requires coating) |

Naturally corrosion-resistant |

|

Cost |

Lower cost |

Higher cost due to cobalt |

|

Brittleness |

Less brittle |

More brittle |

|

Applications |

EVs, wind turbines, electronics |

Aerospace, medical, high-temp motors |

Where to buy rare earth magnets locally?

Stanford Magnets is a company that specializes in manufacturing and offering magnetic materials in the USA, our products business range includes: NdFeB magnets, ferrite magnets, AlNiCo magnets, SmCo magnets, plastic magnets, rubber magnet, etc., the quality has gained customer consistent high praise.

How to safely use powerful magnets?

Powerful magnets should be used in the process to ensure that the workplace is clean. Otherwise, it is easy to adsorb small magnetic particles such as iron chips affect the use. For small specifications, attention should be paid to avoid knocking and breaking, and for large specifications, more attention should be paid to personal safety and protection. High-strength magnets should be kept ventilated and dry in the room when they are stored. Otherwise, the wet environment will easily cause the magnets to rust.

Conclusion

Rare earth magnets are indispensable in modern technology for their unmatched strength. Whether you require maximum strength, compactness, or reliability in extreme conditions, rare earth magnets provide the power and versatility to drive innovation across industries. For more information or assistance, feel free to reach out to Stanford Magnets—your trusted expert in magnetic solutions.