Features & Characteristics of Ceramic Magnets

Ceramic magnets are also called ferrite magnets. As a part of the permanent magnet family, they are currently the lowest-cost hard magnets. Ceramic magnets or ferrite magnets are composed of strontium carbonate and iron oxide. They have medium magnetic strength and can be used at relatively high temperatures. Moreover, ceramic magnets are resistant to corrosion and easy to magnetize. These features and characteristics of ceramic magnets make them a great choice for consumer, commercial, industrial, and technical applications.

Features & Characteristics of Ceramic Magnets

Features & Characteristics of Ceramic Magnets

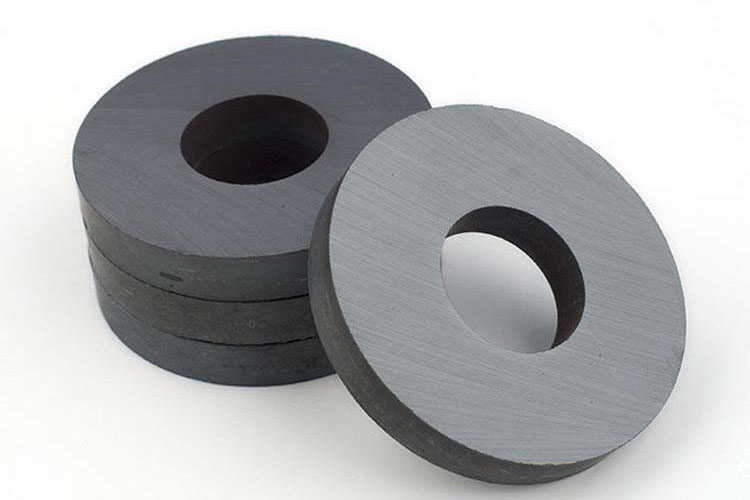

The Grades & Shapes of Ceramic Magnets

Ceramic magnets from Grade 5 (most commonly used) to Grade 8 have disc, block (rectangular and square), and ring shapes. Stanford Magnets have a large number of ceramic discs, blocks (rectangular and square) as well as ring and round cup magnets, which are available for immediate purchase. Besides, in order to fit your exact specifications, Stanford Magnets can also custom-manufacture ceramic magnets. Just send us a request for a quote or contact us to let us know your needs, and our experienced team of engineers will work with you to determine the most economical solution for your project.

The Temperature Considerations for Ceramic Magnets

Ceramic magnets can be used at relatively high temperatures, although their magnetic properties will decrease with increasing temperature. At 175 degrees Celsius (350 degrees Fahrenheit), approximately 75% of their room-temperature magnetic properties are retained.

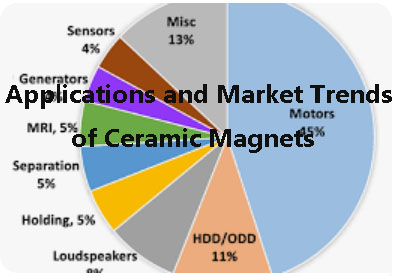

Common Applications of Ceramic Magnets

Ceramic magnets or ferrite magnets are currently the cheapest hard magnets available. They have excellent oxidation resistance and usually do not need additional protective coatings or surface treatments. As such, they are the first choice for all types of consumer, business, and industrial applications. Common applications of ceramic magnets include loudspeakers, motors, generators, switches, sweeper magnets, DIY home projects, lifting machinery, fridge magnets, whiteboards, science experiments, classroom displays, store signage, retail displays, home decor, breaks & clamps, school projects, guitar pick-ups, eddy current devices, relays, etc.

The Manufacturing Methods of Ceramic Magnets

Ceramic magnets (ferrite magnets) require special processing techniques and they should be processed in an "unmagnetized" state. Stanford Magnets is fully capable of machining these materials according to your requirements, so just send us a special request to let us know what you are looking for.

The Bonding Methods of Ceramic Magnets

People usually use "super glue" (such as Loctite 325 or other epoxy resins) to assemble ceramic magnets into products. Before bonding, one needs to make sure that the bonding surfaces are clean and dry.

Safety Precautions When Using Ceramic Magnets

Ceramic magnets are hard and brittle and can chip or break if they fall on the ground. Therefore, we need to take special care when handling these magnets!

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the features and characteristics of ceramic magnets. If you want to find more information about ferrite magnets, we would like to advise you to visit Stanford Magnets. Stanford Magnets is a leading magnet supplier across the world, that has been involved in R&D, manufacturing, and sales of magnets since the 1990s. It provides customers with high-quality Ceramic Magnets, Samarium Cobalt Magnets, Neodymium Magnets, and AlNiCo Magnets at a very competitive price.