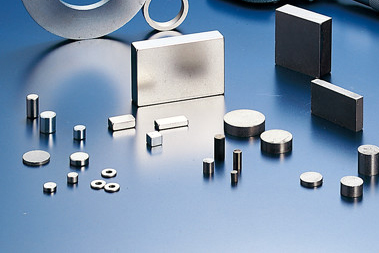

Neodymium Iron Boron (Nd-Fe-B)

Neodymium Iron Boron (Nd-Fe-B) Basics

Sintered neodymium-iron-boron (Nd-Fe-B) magnets are the most powerful commercialized permanent magnets available today, with maximum energy product ranging from 26 MGOe to 52 MGOe.

Nd-Fe-B is the third generation of permanent magnet developed in the 1980s. It has a combination of very high remanence and coercivity, and comes with a wide range of grades, sizes and shapes.

With its excellent magnetic characteristics, abundant raw material and relatively low prices, Nd-Fe-B offers more flexibility in designing of new or replace the traditional magnet materials such as ceramic, Alnico and Sm-Co to achieve high efficiency, low cost and more compact devices.

A powder metallurgy process is used in producing sintered Nd-Fe-B magnets. Although sintered Nd-Fe-B is mechanically stronger than Sm-Co magnets and less brittle than other magnets, it should not be used as structural component.

Selection of Nd-Fe-B is limited by temperature due to its irreversible loss and moderately high reversible temperature coefficient of Br and Hci. The maximum application temperature is 200 °C for high coercivity grades. Nd-Fe-B magnets are more prone to oxidation than any other magnet alloys. If Nd-Fe-B magnet is to be exposed to humidity, chemically aggressive media such as acids, alkaline solutions salts and harmful gases, coating is recommended. It is not recommended in a hydrogen atmosphere.

Property Table for Neodymium Iron Boron (Nd-Fe-B)

|

Property |

Notes |

|

|

Chemical Composition |

Nd₂Fe₁₄B (with minor additives like Dy, Co) |

May include dysprosium or terbium to improve thermal stability. |

|

Maximum Energy Product (BHmax) |

30 – 52 MGOe (239 – 414 kJ/m³) |

N52 grade provides the highest known value for commercial magnets. |

|

Remanence (Br) |

1.0 – 1.48 T (10,000 – 14,800 Gauss) |

Indicates the magnet's residual flux density. |

|

Coercivity (Hc) |

750 – 2000 kA/m |

Intrinsic coercivity can go up to 3000 kA/m with dysprosium doping. |

|

Curie Temperature |

310 – 400 °C |

Typically around 320 °C for standard NdFeB; varies with alloy composition. |

|

Maximum Operating Temp. |

80 – 230 °C |

Depends on grade; higher grades (e.g. N48SH) operate up to 150–230 °C. |

|

Density |

~7.5 g/cm³ |

Higher than ferrite (~5.0 g/cm³). |

|

Electrical Resistivity |

~150 μΩ·cm |

Low resistivity; prone to eddy current losses if not laminated or coated. |

|

Corrosion Resistance |

Poor (without coating) |

Typically coated with nickel, epoxy, or Parylene for protection. |

|

Mechanical Strength |

Brittle |

Not suitable for structural loads; chips and cracks easily if mishandled. |