All about Sintered NdFeB Magnets

Sintered Neodymium Iron Boron (NdFeB) magnets—most folks just call them neodymium magnets—are at the top of the food chain when it comes to permanent magnets. These little powerhouses are what make modern electronics hum and electric motors spin with efficiency we couldn’t dream of a few decades ago. They’re in your earbuds, your car, wind turbines, and even life-saving medical equipment.

This article covers multiple aspects of sintered NdFeB magnets tick—from what they’re made of to how they’re made, their strengths and quirks, and where you’ll find them in the real world.

Fig. 1 Sintered NdFeB Magnets

Learn about NdFeB Magnets

--What Are NdFeB Magnets

NdFeB magnets are made of three main ingredients: neodymium, iron, and boron. Put together, they form a compound with incredibly strong magnetic properties. What really makes them stand out is their ability to pack a strong magnetic punch in a small size. They’re what you turn to when you need powerful magnets but don’t have a lot of room to work with.

--Types of NdFeB Magnets

Now, neodymium magnets come in different types depending on how they’re made. There are sintered, bonded, and hot-pressed versions. The sintered ones—our focus here—are made through a method that compacts and heats powdered material into solid magnets. This process makes them denser and more powerful than the bonded type, which are molded with plastic.

Bonded NdFeB Magnets vs Sintered NdFeB Magnets

Fundamentals of Sintered NdFeB Magnets

--Composition and Crystal Structure

The magic behind sintered NdFeB magnets lies in their structure. The base formula is Nd₂Fe₁₄B, which has a nice little tetragonal crystal structure. This structure is what gives these magnets their impressive strength. It lines up the atoms in a way that naturally supports strong magnetism.

Sometimes, to beef up their resistance to heat or improve their durability, elements like dysprosium (Dy) and terbium (Tb) are mixed in. These aren’t cheap ingredients, though, so using them comes with a trade-off—better performance, but at a higher cost. Still, if you need your magnets to hold strong in high-heat environments (like under the hood of a car), they’re worth it.

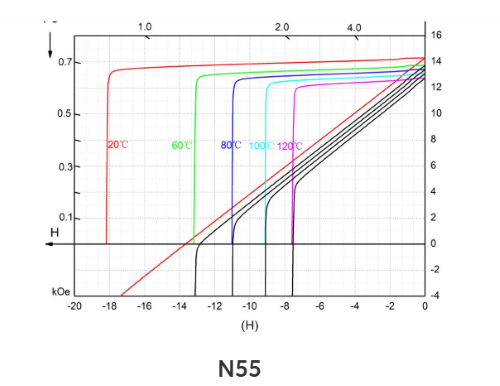

Fig. 2 Demagnetization Curve of Sintered NdFeB Magnets

--Manufacturing Process

Making sintered NdFeB magnets is a real engineering ballet. Every step has to be done just right. Here’s how it goes:

- Alloying and Melting: We start by melting neodymium, iron, boron, and any extra elements together. The goal is to make a uniform alloy, kind of like making a good cake batter—consistency is key.

- Hydrogen Decrepitation: After the alloy cools, it’s broken down using hydrogen gas. The hydrogen causes the alloy to crack into chunks, which makes the next grinding step easier.

- Jet Milling: These chunks are ground into a fine powder using high-speed jets. You want really tiny particles here—think of it like turning rock salt into flour.

- Pressing: The powder is then pressed into shape while under a magnetic field. That magnetic field is important—it lines up the magnetic domains to give you a stronger final magnet.

- Sintering and Annealing: Now comes the heat. The pressed magnets are baked at high temperatures to solidify them. After that, they’re annealed—basically given a heat soak—to relieve stress in the material and enhance magnetic properties.

- Machining: Once cooled, the magnets are cut or ground down to the exact sizes needed. Since sintered magnets are a bit brittle, this step has to be done carefully.

- Surface Treatment: Neodymium magnets don’t like moisture—without protection, they’ll rust. So we coat them, usually with nickel, zinc, or epoxy, to keep corrosion at bay.

- Magnetization: Last but not least, the magnets are hit with a powerful magnetic field to lock in their magnetic orientation. After this step, they’re ready to go.

This whole process ensures that the magnets are strong, reliable, and ready for action in demanding applications.

How Are Sintered NdFeB Magnets Made?

--Magnetic Properties of Sintered NdFeB Magnets

Sintered NdFeB magnets are the workhorses of modern magnetism. Here’s what makes them stand out:

- High Remanence (Br): This means they retain a strong magnetic field after being magnetized. Handy when you want your magnets to stay powerful.

- High Coercivity (Hc): These magnets resist demagnetization, even in tough environments. That’s important for motors, where magnetic fields are constantly shifting.

- High Energy Product (BHmax): This is a measure of how much magnetic energy a magnet can store. Sintered NdFeB magnets score high, which means more power in a smaller package.

But they do have a weak spot: temperature. The Curie temperature—the point at which they start losing their magnetism—is between 310°C and 370°C. To make them work better in high heat, that’s when we add expensive stuff like dysprosium.

Table 1 Magnetic Properties of Sintered NdFeB Magnets

|

Br mT/kGs |

Hcb kA/m or kOe |

H or kOe |

BH kJ/m3 or MGOe |

Max Tem °C |

||

|

1 |

N55 |

1470-1530 (14.7-15.3) |

≥860(≥10.8) |

≥876(≥11) |

414-438 (52-56) |

70 |

|

2 |

1430-1480 (14.3-14.8) |

≥860(≥10.8) |

≥876(≥11) |

398-422 (50-53) |

70 |

|

|

3 |

N50 |

1400-1450 (14.0-14.5) |

≥860(≥10.8) |

≥960(≥12) |

382-406 (48-51) |

70 |

|

4 |

N48 |

1380-1420 (13.8-14.2) |

≥836(≥10.5) |

≥900(≥11) |

366-390 (46-49) |

80 |

|

5 |

N45 |

1320-1380 (13.2-13.8) |

≥876(≥11.0) |

≥960(≥12) |

342-366 (43-46) |

80 |

|

6 |

N42 |

1280-1320 (12.8-13.2) |

≥923(≥11.6) |

≥960(≥12) |

318-342 (40-43) |

80 |

|

7 |

N40 |

1250-1280 (12.5-12.8) |

≥923(≥11.6) |

≥960(≥12) |

302-326 (38-41) |

80 |

|

8 |

N38 |

1220-1250 (12.2-12.5) |

≥899(≥11.3) |

≥960(≥12) |

287-310 (36-39) |

80 |

|

9 |

1180-1220 (11.8-12.2) |

≥868(≥10.9) |

≥960(≥12) |

263-287 (33-36) |

80 |

|

|

10 |

N33 |

1130-1180 (11.3-118) |

≥836(≥10.5) |

≥960(≥12) |

247-270 (31-34) |

80 |

|

11 |

N30 |

1080-1130 (10.8-11.3) |

≥796(≥10) |

≥960(≥12) |

223-247 (28-31) |

80 |

For more specific data, please check Stanford Magnets.

--Applications of Sintered NdFeB Magnets

So, where do these magnets end up? Pretty much everywhere.

- Electronics: Utilized in hard disk drives, headphones, and loudspeakers for their compact size and strong magnetic fields.

- Automotive Industry: Integral in electric vehicle motors, power steering, and various sensors.

- Renewable Energy: Employed in wind turbine generators to enhance efficiency.

- Medical Devices: Found in MRI machines and other diagnostic equipment.

- Industrial Automation: Used in robotic systems and magnetic separators.

In short, if it's high-tech, powerful, or automated—there’s a good chance there’s a sintered NdFeB magnet inside.

Conclusion

Sintered NdFeB magnets have changed the game for how we use and think about magnetism in modern technology. They bring power, efficiency, and reliability to everything from smartphones to wind turbines. But like all engineering materials, they come with trade-offs. They can be brittle, sensitive to moisture, and pricey when you add rare-earth elements to boost performance. Still, with ongoing research and smarter manufacturing techniques, we’re constantly finding ways to get more out of them.

For engineers, designers, or curious minds, understanding how these magnets work isn’t just interesting—it’s essential. They’re at the heart of the devices shaping our future.