Types of Magnets: A Comprehensive Overview

Introduction

Magnets are a fundamental part of modern life, powering everything from household appliances to industrial equipment. The science of magnetism is vast, but at its core, magnets can be categorized into several types based on their durability and material composition.

This article will discuss the differences between permanent and temporary magnets, talk about the various types of permanent magnets, and highlight some special categories of magnets that have unique properties and applications.

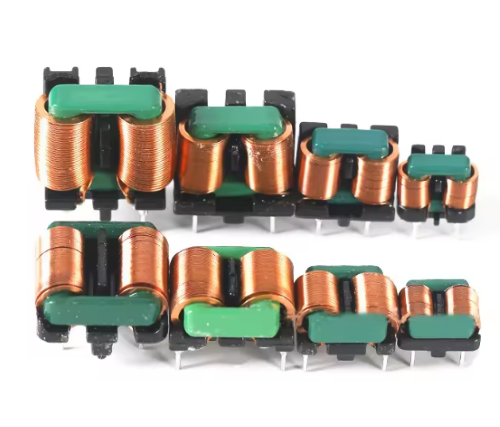

Fig. 1 Strong Permanent Magnets

Permanent Magnets vs Temporary Magnets

Permanent Magnets are those which retain their magnetic properties over a long period. These magnets are made from materials that naturally maintain their magnetic field without requiring an external electric current. Permanent magnets are used in a myriad of applications including sensors, speakers, and motors. Their ability to constantly emit a magnetic field makes them indispensable in many technologies.

Table 1 Permanent Magnets vs Temporary Magnets

| Type | Properties | Uses |

|---|---|---|

| Permanent Magnets | Retain magnetism without power. Durable and stable. | Motors, electronics, industrial tools. |

| Temporary Magnets | Magnetic only with an external field. Easy to magnetize. | Electromagnets, transformers, relays. |

| Electromagnets | Magnetic field from electric current. Controllable strength. | Motors, generators, magnetic lifts, MRI. |

| Superconducting Magnets | Extremely strong. Require cooling to work. | MRI, particle accelerators, scientific research. |

Temporary Magnets, on the other hand, act like magnets only when they are within a strong magnetic field. They lose their magnetism when the external field is removed. Temporary magnets are made from soft metals that are easy to magnetize but their magnetic properties are fleeting. Common uses of temporary magnets include electric bells and relays where magnets are only required to function when electric current is present.

Types of Permanent Magnets

Permanent magnets themselves can be divided into several types based on their compositions:

1. Ceramic or Ferrite Magnets

Definition: Ceramic, or ferrite magnets, consist of a mix of iron oxide and strontium carbonate, and they are manufactured through pressing or sintering processes.

Outstanding Feature: These magnets are highly resistant to demagnetization and corrosion, which makes them very durable under various environmental conditions.

Applications: They are widely utilized in electric motors, magnetic separators, and speakers, as well as in devices that require magnetic hold-downs.

2. Alnico Magnets

Definition: Alnico magnets are composed of an alloy that includes aluminum, nickel, cobalt, and iron, along with small amounts of other elements. They can be created through either casting or sintering.

Outstanding Feature: These magnets are noted for their excellent temperature stability and their ability to produce a high magnetic flux density.

Applications: They are ideal for use in applications that operate at high temperatures, such as sensors and volt meters, and where a stable magnetic field is needed across a wide temperature range.

Fig. 2 Types of Magnets

3. Samarium Cobalt (SmCo) Magnets

Definition: Part of the rare earth magnet category, SmCo magnets are made from an alloy of samarium and cobalt.

Outstanding Feature: These magnets offer excellent thermal stability and are resistant to demagnetization.

Applications: Their properties make them suitable for aerospace, military, and other high-temperature industrial applications.

Grades: The series, including SmCo5 and Sm2Co17, refer to their chemical compositions, with various grades available that correspond to different energy products and temperature resistances.

4. Neodymium Iron Boron (NdFeB) Magnets

Definition: NdFeB magnets, another group of rare earth magnets, are composed of neodymium, iron, and boron and are known as the most powerful permanent magnets available today.

Outstanding Feature: These magnets have exceptionally high magnetic properties and an impressive energy product, which allows for their use in smaller sizes compared to other magnets with similar capabilities.

Applications: They find uses in diverse applications, including hard disk drives, electric motors, MRI machines, and magnetic therapy devices.

Grades: Available in various grades such as N35, N42, N52, etc., these numbers indicate the maximum energy product. The higher the number, the stronger the magnet. They also come in different coatings such as nickel, zinc, or epoxy to enhance corrosion resistance.

Related reading: What are the Four Types of Magnets?

Choosing the right type of permanent magnet for an application requires understanding these fundamental differences in their properties, applications, and grades. Each type offers unique benefits suited to specific environments and uses (See Table 1). Hope that you can get magnet materials with optimal performance and durability.

Table 2. Types of Permanent Magnets

|

Type |

Composition |

Outstanding Feature |

Applications |

|

Iron oxide and strontium carbonate |

Highly resistant to demagnetization and corrosion |

Electric motors, magnetic separators, speakers, hold-downs |

|

|

Aluminum, nickel, cobalt, iron, and other elements |

Excellent temperature stability and high magnetic flux density |

High-temperature applications, sensors, volt meters |

|

|

Samarium and cobalt |

Excellent thermal stability and resistance to demagnetization |

Aerospace, military, high-temperature industrial applications |

|

|

Neodymium, iron, and boron |

High magnetic properties and energy product |

Hard disk drives, electric motors, MRI machines, magnetic therapy |

Fig. 3 Comparing Four Types of Magnets

Types of Special Magnets

Beyond the conventional permanent and temporary magnets, there are special types of magnets that are engineered for specific, high-tech applications:

- Comprised of a coil of wire wound around a metal core, Electromagnets produce magnetic fields when electric current passes through them. Their strength can be adjusted by changing the current's intensity, making them extremely versatile. Electromagnets are pivotal in the automotive and machinery industries for lifting heavy metal objects and in medical devices such as MRI machines.

- Superconducting Magnets are made from materials that exhibit superconductivity when cooled below a certain temperature. Superconducting magnets are capable of producing the highest magnetic fields and are most famously used in particle accelerators and experimental magnetic levitation trains.

- Made from a mixture of ferrite powder and rubber polymer resin, Flexible Magnets are easy to cut and shape. While they are not particularly strong, their flexibility makes them perfect for advertising signage, magnetic sheets for crafts, and novelty items.

- Rare Earth Magnets, including Neodymium (NdFeB) and Samarium-Cobalt (SmCo), are crafted from rare earth elements and are known for their exceptional strength, with neodymium being the stronger of the two. These magnets are essential in applications that require strong, compact magnets, such as hard drives, electric motors, and jewelry clasps. Samarium-Cobalt magnets, while slightly weaker, offer superior temperature stability and corrosion resistance, making them ideal for aerospace and military applications.

Conclusion

The science of magnetism encompasses a broad range of materials, each with distinct properties and applications. From the strong, permanent magnets that power electronic devices to the high-tech superconducting and flexible magnets that open new possibilities in medical and industrial fields, magnets continue to be at the forefront of technological innovation. As our understanding of magnetic materials grows, so too will their applications, influencing numerous aspects of modern life and future technologies. For more information, please check Stanford Magnets.