Features & Characteristics of AlNiCo Magnets

Alnico magnet is an alloy composed of metal aluminum, nickel, cobalt, iron, and other trace metal elements. It is widely used in various instruments and other high-temperature applications. According to their different production processes, AlNiCo magnets can be divided into sintered AlNiCo magnets and cast AlNiCo magnets. In this article, let's take a deeper look at the features & characteristics of AlNiCo magnets.

Features & Characteristics of AlNiCo Magnets

1. What are the main characteristics of alnico magnets?

AlNiCo magnets have high magnetic field strength and energy, but they have lower coercivity. Compared with rare earth magnets, they are less brittle, strong in corrosion resistance, and have excellent temperature stability, so they can be used at very high temperatures. Just as I have mentioned above, ALNICO magnets can be manufactured through either a casting or sintering process and made into various complex shapes, such as horseshoe shapes, which cannot be achieved with other magnet materials.

2. What grades & shapes are available for alnico magnets?

The most commonly used Alnico grades are grades 5 and 8. Non-standard shapes can be customized according to the specifications of the drawings. Stanford Magnets can customize almost any shape and size of alnico magnets to meet your special requirements. If you send us a request for a quote, we'll work with you to determine the most economical way to manufacture your alnico magnets.

3. Are there machining constraints for Alnico magnets?

Machining or drilling of alnico magnets cannot be done by conventional methods. They shall be cut and ground before magnetization. The holes of the alnico magnets must be made by the EDM method. Stanford Magnets are fully capable of processing these materials according to your specifications.

4. What are some common applications for alnico magnets?

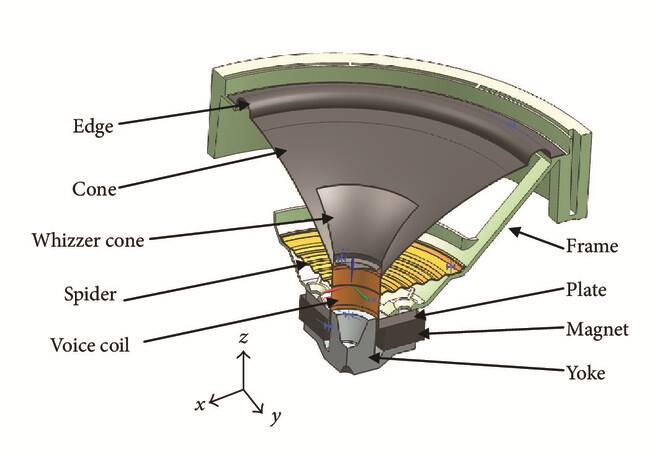

The most common applications for alnico magnets are instrumentations, meters, microwave devices, actuators, holding devices, sensors, etc.

5. Do alnico magnets require surface treatments?

Alnico magnets usually do not require protective coatings or coatings because of their excellent corrosion resistance.

6. What safety precautions should be taken when using alnico magnets?

When we use alnico magnets, we should take extra care to make sure that they are not affected by the adverse repelling fields, which may partially demagnetize the magnets. If partially demagnetized, they can be easily remagnetized.

Conclusion

Thank you for reading our article and we hope it can help you to have a better understanding of the features and characteristics of AlNiCo magnets. If you want to know more about AlNiCo magnets, we would like to advise you to visit Stanford Magnets for more information. Stanford Magnets is a leading magnet supplier across the world who has been involved in R&D, manufacturing, and sales of AlNiCo magnets since the 1990s. It provides customers with high-quality rare earth permanent magnetic products, and other non-rare earth permanent magnets at a very competitive price.