Injection Molded Ferrite Magnets VS Sintered Ferrite Magnets

Both injection-molded ferrite magnets and sintered ferrite magnets belong to the category of ferrite magnets, but there are obvious differences between them. So, injection molded ferrite magnets vs sintered ferrite magnets, what are the differences between them? In this article, we'll try to answer this question.

Injection Molded Ferrite Magnets VS Sintered Ferrite Magnets

Injection Molded Ferrite Magnets VS Sintered Ferrite Magnets

Advantages and Features of Injection Molded Ferrite Magnets

First of all, the production process of injection-molded ferrite magnets determines the physical properties of injection molded ferrite magnets. Molds must be used to produce injection-molded ferrite magnets. This is the same as the sintered ferrite magnets. Injection-molded ferrite magnets cannot be produced without molds. Injection-molded ferrite magnets are divided into isotropic and anisotropic, mainly reflected in the difference in the composition of the magnet material. The material composition of the injection-molded ferrite magnet contains a certain plastic component. The injection-molded ferrite magnet produced by the mold has the characteristics of high precision, uniform magnetic distribution, stable magnetic properties, and easy processing and production. Any injection-molded ferrite magnet must rely on mold production and processing, and the magnetizing method needs to rely on magnetizing fixtures. Injection-molded ferrite magnets are mostly used in various water flow open tubes, Hall sensor elements, electronic appliances, precision instruments, and other products.

Advantages and Features of Sintered Ferrite Magnets

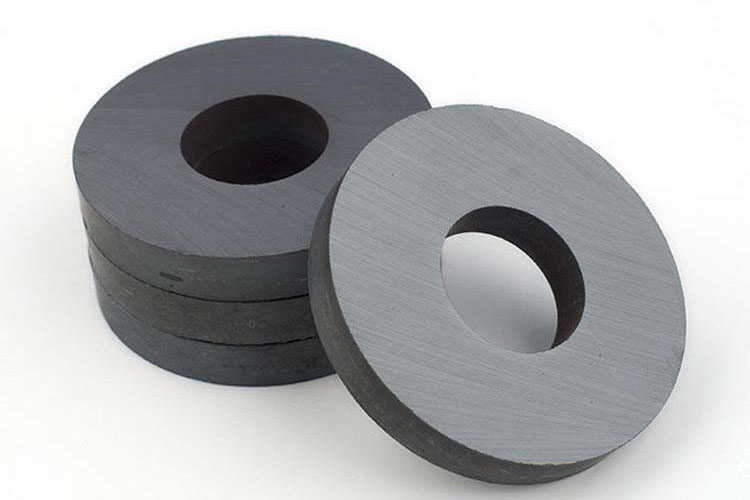

The sintered ferrite magnet is a kind of ferrite magnet that is more common in our lives. It has a black surface and stable magnetic properties, which is a major advantage of sintered ferrite magnets. Sintered ferrite magnets, like injection-molded ferrite magnets, rely on molds for production. Since ferrite magnets are divided into isotropic ferrite and anisotropic ferrite magnets in terms of material, what is the difference between the two types of ferrite magnets in the production mold? This question is very important. Isotropic ferrite magnets are weak ferrite magnets, and the magnet mold has a sufficiently large advantage in terms of cost. The isotropic ferrite magnet itself also has a major defect, that is, the magnetism of the isotropic ferrite magnet is very weak. On the contrary, compared with isotropic ferrite magnets, anisotropic ferrite magnet molds are expensive. At the same time, the magnetic properties of anisotropic ferrite magnets are relatively strong.

Differences between Injection Molded Ferrite Magnets and Sintered Ferrite Magnets

Injection-molded ferrite magnets and sintered ferrite magnets are also quite different in temperature resistance. The maximum temperature resistance of injection molded ferrite magnets is only about 100 degrees, while the temperature resistance of sintered ferrite magnets can reach more than 400 degrees.

Conclusion

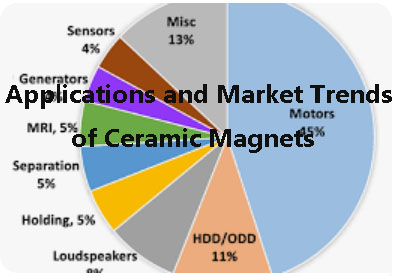

Thank you for reading our article and we hope it can help you to have a better understanding of the injection-molded ferrite magnets and sintered ferrite magnets. If you want to learn more about ferrite magnets or other types of magnets, we would like to advise you to visit Stanford Magnets for more information. As a leading magnet supplier across the world, Stanford Magnets has been involved in R&D, manufacturing, and sales of magnets since the 1990s. It provides customers with high-quality permanent magnets like SmCo magnets, neodymium magnets, AlNiCo magnets, and ferrite magnets (ceramic magnets) at a very competitive price.