Magnetic Materials: Isotropic VS. Anisotropic

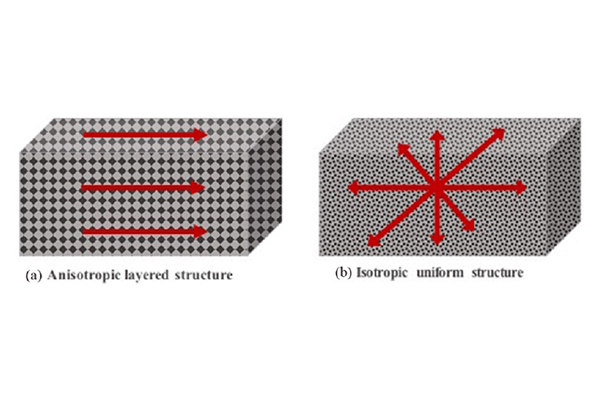

Magnetic materials can either be described as isotropic or anisotropic. This largely depends on how direction affects their magnetic property. What are isotropic materials and how do they compare to anisotropic materials? Isotropic magnets are magnets that do not have their magnetic properties dependent on their magnetization direction. For these magnets, magnetization can occur in any direction. During manufacturing, isotropic magnets are not oriented in any preferred direction. They usually have weaker magnetic properties than anisotropic magnets. However, they are not as costly as anisotropic magnets. Anisotropic magnets are magnets that have their magnetic properties dependent on their magnetization direction. What this means is that they have different levels of magnetism in varying magnetization directions. When manufactured, they are aligned in their future magnetization direction. These magnets have a preferred magnetization direction. Outside this direction, they cannot be magnetized. An advantage of this type of magnet is that it has stronger magnetic properties than isotropic magnets. The majority of magnets used in the world are anisotropic. These magnets are oriented during manufacture.

Further Reading: Magnetic Anisotropy And Anisotropic Materials

Damiati, Laila & Eales, Marcus & Nobbs, Angela & Su, Bo & Tsimbouri, Penelope & Salmerón-Sánchez, Manuel & Dalby, Matthew. (2018). Impact of surface topography and coating on osteogenesis and bacterial attachment on titanium implants.

Isotropic VS. Anisotropic: Similarities

- Magnets made from both types of materials attract ferromagnetic objects.

- When suspended freely, magnets from both types of materials point in the north-south direction.

- Magnets made from both types of material attract opposite poles and repel like poles.

Isotropic VS. Anisotropic: Differences

Manufacture

The method of manufacture for isotropic materials differs from the method of manufacture for anisotropic materials. Isotropic materials are not oriented during manufacture. Anisotropic materials, on the other hand, are oriented during manufacture.

Strength

Both types of material differ in strength. Anisotropic magnets usually have stronger magnetic properties than isotropic magnets because they are oriented in a particular direction.

Cost

Anisotropic magnets cost more than isotropic magnets. This is because orienting anisotropic magnets requires more time and resources.

Anisotropic Magnets

Most of the magnets used in the world are anisotropic. This means they have a preferred magnetization direction based on their orientation during manufacture.

Pros

- These types of magnets are very difficult to demagnetize.

- Anisotropic magnets generally generate a stronger magnetic field than isotropic magnets.

Cons

- Anisotropic magnets cost more to produce.

Sintered Neodymium Magnets

Sintered neodymium magnet is an example of an anisotropic magnet. Sintered neodymium magnets are produced in such a way that the grains are oriented in a preferred direction for magnetization. To produce sintered neodymium magnets, the alloy is first magnetized and poured into a cast where it is cooled. In the next step, the alloy is ground into fine powder. The powder is placed in a magnetic field and its shape is formed under high pressure. This step of sintered neodymium manufacture is very important because it determines the preferred magnetization direction of the magnet. Subsequently, when the finished magnets are placed in a magnetic coil, the magnetic field of the coil will be in the same direction as the crystal lattice of the sintered neodymium magnets. It is this magnetic field from the coil that will magnetize the sintered neodymium magnets permanently.

Isotropic Magnets

Isotropic magnets have their crystals oriented in different directions and are not magnetized in a particular direction.

Pros

- Isotropic magnets are less expensive than anisotropic magnets.

Cons

- They are easier to demagnetize than anisotropic magnets.

- They generate a weaker magnetic field than isotropic magnets.

Bonded Neodymium Magnets

This is an example of an isotropic magnet. To make a bonded neodymium magnet, mix an Nd-Fe-B alloy with an epoxy binder. The epoxy binder makes up 3 % of the mixture while the alloy makes up 97 %. For the second step, compress the mixture and put it in an oven for curing. No magnetic field is added while compressing the mixture. Therefore, the finished product has no preferred magnetization direction.

Further Reading: Bonded NdFeB Magnets vs Sintered NdFeB Magnets

Magnetization Direction of Anisotropic Magnets

We have learned that anisotropic magnets have a preferred magnetization direction. However, we have not delved into the different magnetization directions an anisotropic magnet could prefer. Below are the magnetization directions for anisotropic magnets.

Axial Magnetization Direction

Axial magnetization is directed along the axis of the magnet just as the name suggests. This is the more popular magnetization direction. A magnet magnetized in this direction will exert more force when the flat surface is near the material you want it to attract.

Diametrical Magnetization Direction

Unlike axial magnetization direction, diametric magnetization direction occurs along the diameter of the magnet. In diametrical magnetization, the poles can be found on the curved side of the magnet if the magnet is cylindrical. This implies the magnet will exert a greater pull if the curved side is near the material you want it to attract.

Conclusion

Now that you know that you know the differences and similarities between isotropic and anisotropic magnetic materials, you can easily decide on the best one for you. Some other factors to consider include budget and purpose. If you want to learn more about magnetic materials, we would like to advise you to visit Stanford Magnets for more information.