What You Need to Know about Ceramic Magnets

Many industrial applications utilize permanent magnets. A unique type of permanent magnet used in most of these applications is ceramic magnets. They have an impressive set of features that make them valuable materials. Here, we discuss what ceramic magnets are, as well as their applications in daily life and industrial processes.

What Is Ceramic Magnet?

Ceramic magnets, otherwise known as ferrite magnets, are a widespread type of permanent magnets. They are known for their medium magnetic strength and ability to withstand fairly high temperatures. Ceramic or ferrite magnets are mainly composed of strontium carbonates or barium carbonate, and iron oxide.

Features & Characteristics of Ceramic Magnets

They are the most affordable, hard markets available on the market today. You most likely have seen them: they are the small, round black magnets we see often. Generally, ceramic magnets are sintered from iron oxide and other essential raw materials, such as strontium carbonate. They are broadly classified into three main categories: permanent, soft, and gyromagnetic ceramic magnets.

How to Make Ceramic Magnets

Ceramic magnets are produced using powder metallurgy techniques.

- The process begins with iron oxide mixed with either barium carbonate or strontium carbonate, which is then heated to temperatures of 1800-2000°F to form ferrite material. This material is finely ground using wet milling, resulting in a small particle size.

- The milled powder is then either dried for dry pressing or injected as a wet slurry into a die. In the presence of a magnetic field, the material is compacted, helping the ferrite particles align properly.

- The compacted material is then sintered at approximately 2000°F, making it fully dense. Due to the hardness and brittleness of ceramic magnets, all finishing processes, such as grinding, are performed using diamond wheels to meet precise customer specifications.

Types of Ceramic Magnets

Unlike permanent ceramic magnets, the residual magnetic field is infinitesimal or non-existent when the magnetic field wears off or disappears. Hence, they are called soft magnets. Gyromagnetic ceramic magnets, on the other hand, are magnets or magnetic materials with gyromagnetic properties. They are used extensively in microwave communications.

Based on their varying magnetic strength and uses, ferrite/ceramic magnets can be classified into 5 main groups:

- Soft magnets: these are ferrite magnetic materials that can easily be magnetized and demagnetized in weak magnetic fields, such as nickel-zinc ferrite. This type of ceramic magnets are used primarily on inductance components like filter core, radio core, tape recording, etc., and they serve as the key material of magnetic recording elements.

- Permanent magnet: these have a basic hexagonal structure. Their magnetic properties tend to be permanent, hence the name permanent magnet. They are used extensively in telephones, generators, telephones, loudspeakers, television, etc.

- Hard magnet: These are Ferrite hard magnetic materials, which are difficult to demagnetize. You’ll find them in recorders, loudspeakers, and magnetic cores of most telecommunication devices.

- Moment magnet: Ferrite moment magnetic materials are magnetic materials with rectangular hysteresis loops. A small external magnetic field typically magnetizes it, and it retains its magnetic property even after the external magnetic field is removed. They are primarily used in the memory cores of various electronic computers.

- Ferrite gyromagnetic material: These are magnetic materials with rotary magnetism. They typically have various microwave devices with microwave transmission lines.

Basic Characteristics about Ceramic Magnets

Ceramic magnets find their way into many critical applications (such as their use in moderately high-temperature situations and the making of magnetic separation equipment) because of some of the features and characteristics of ceramic magnets:

- Ceramic magnets do not have very high magnetic properties, but they possess medium magnetic strength, making them desirable materials for several processes.

- They perform relatively well in pretty high temperatures

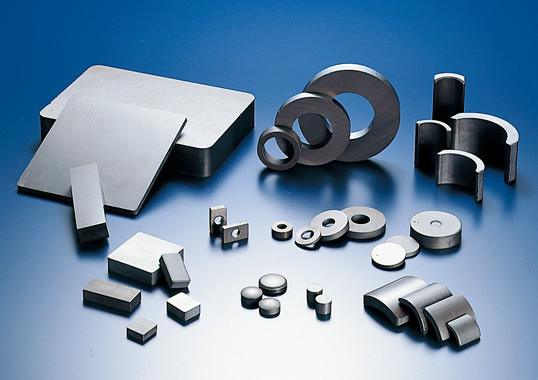

- They are manufactured in the ring, disc, and block standard shape, but they can also be manufactured in the custom specification. This makes ceramic magnets even more helpful in varying applications.

- They do not need to be treated or protected for surface rust. They are naturally resistant to corrosion

- They have high intrinsic coercive force

- They are hard and brittle

-

Cost-Effective – Ceramic magnets are one of the most economical types of permanent magnets due to the abundant availability of raw materials and relatively simple manufacturing process.

-

Good Magnetic Strength – While not as strong as rare-earth magnets (such as neodymium), ceramic magnets provide sufficient magnetic force for many industrial and consumer applications.

-

High Resistance to Corrosion – Unlike metal-based magnets, ferrite magnets do not rust and can function effectively in humid or wet environments.

-

Brittle and Hard – Ceramic magnets are very hard but also brittle, meaning they can chip or break if dropped or handled roughly.

-

Temperature Stability – They perform well in high-temperature environments and maintain their magnetic properties up to 250°C.

-

Electrical Insulation – Unlike metal magnets, ceramic magnets are non-conductive, making them ideal for applications where electrical insulation is required.

Applications of Ceramic Magnets

-

Electronics – Used in speakers, microphones, and sensors.

-

Automotive Industry – Found in motors, ignition systems, and fuel injectors.

-

Medical Equipment – Used in MRI machines and medical sensors.

-

Household Appliances – Common in refrigerator seals, vacuum cleaners, and washing machines.

-

Industrial Applications – Employed in magnetic separators, conveyor systems, and holding devices.

Conclusion

Ceramic magnets are very useful magnetic materials, which come in standard sizes and shapes. While they may not be as strong as rare-earth magnets, their advantages in cost, corrosion resistance, and temperature stability make them an excellent choice for a variety of uses.