NdFeB Magnets for Permanent Magnetic Lifters

Neodymium magnet, also known as NdFeB magnet, is one of the most powerful permanent magnets today and the most commonly used rare earth magnet. NdFeB magnets are widely used in electronic products, such as hard drives, mobile phones, earphones, and battery-powered tools. In this article, we will take a look at the NdFeB magnets for permanent magnetic lifters.

NdFeB Magnets for Permanent Magnetic Lifters

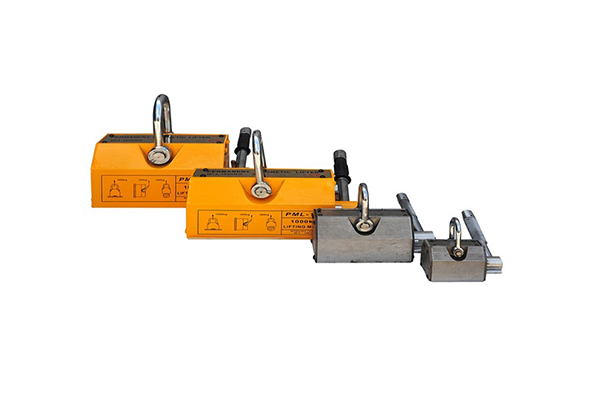

Permanent magnet lifters have the advantages of small size, strong lifting capacity, high safety factor, almost zero remanence, and not easy to demagnetize. They do not need electricity or other energy to drive, only rely on the magnetic force generated by the neodymium iron boron magnets to continuously and stably lift objects. Generally, they can lift several tons of iron blocks, steel plates, and cylindrical iron materials! First, let's take a closer look at NdFeB magnets so that we can better understand the permanent magnet lifters. NdFeB magnets are also called "strong magnets" or "permanent magnets". They are the most commonly used rare earth magnets and can maintain their magnetism for a long time. Usually, the surface of the neodymium magnets we use today needs to be treated, such as electroplating gold, nickel, zinc, and tin, or sprayed with epoxy resin on the surface to avoid corrosion. Then, let's figure out what's a permanent magnetic lifter. The permanent magnetic lifter is such a lifting device that has the advantages of small size, strong lifting capacity, high safety factor, almost zero remanence, not easy to demagnetize, and does not require electricity and other energy to drive, and can continuously and stably hoist objects only by magnetic force. It can generally lift several tons of iron, steel plates, and cylindrical iron materials. Next, let’s take a look at the structure of the permanent magnet lifter to better understand how the neodymium magnet works. Permanent magnet lifters is a strong magnetic system composed of high-performance neodymium iron boron permanent magnets (that is, the magnetic core, composed of multiple neodymium iron boron magnets, is the core component of the entire lifter). The magnetic force of the magnetic core can be changed by turning the handle left and right to hold and release the workpiece. The upper part of the lifter has a hoisting ring for lifting the workpiece, and the bottom part has a V-shaped groove for sucking and holding the corresponding cylindrical object. The permanent magnetic lifter is a new field of permanent magnet application. Taking into account the advantages of permanent magnet lifters, the new direction of the development of lifting technology must be the permanent magnet lifters, while traditional spreaders, electromagnets, and electromagnetic chucks will be gradually eliminated.

Conclusion

Thank you for reading our article and we hope it can help you better understand the NdFeB magnets for permanent magnetic lifters. If you want to learn more about NdFeB magnets or other types of magnets, we would like to advise you to visit Stanford Magnets for more information. As a leading magnet supplier across the world, Stanford Magnets has been involved in R&D, manufacturing, and sales of magnets since the 1990s. It provides customers with high-quality permanent magnets like SmCo magnets, neodymium magnets, AlNiCo magnets, and ferrite magnets (ceramic magnets) at a very competitive price.